Announcement

Collapse

No announcement yet.

Please help! 1981 GS450L cam caps binding

Collapse

X

-

osterizer03

osterizer03

Yeah the head is already all torqued down. Both the caps and journals show no bad signs of wear or damage. The cams spin nice and freely when I set them in the journals and when I finger tighten the caps. Everything binds up with the last 1/4 turn of the second bolt on each cap. I'm using a torque wrench and I'm torquing the bolts to 84 in. Lbs as the book calls for.Last edited by Guest; 08-11-2014, 10:28 AM.

-

Are they the original cam caps and what are you torqueing them down to? Ok torque is correct. are they the same caps that came with your head?My stable

84 GSX1100EFG-10.62 @ 125 mph 64'' W/B.

85 GS1150-9.72@146mph stock W/B.

88 GSXR1100-dragbike 9.18@139.92mph/5.68@118mph.

98 Bandit 1200-9.38@146mph/6.02@121mph.

90 Suzuki GS 1425cc FBG Pro Stock chassis 5.42@124mph

06 GSXR750 10.44@135mph

00 Honda elite 80 pit bike

Comment

-

osterizer03

osterizer03

They are the original caps that came with the motor. I'm aware of them needing to be all from the same motor due to the line boring that's done at the factory. All I did to this motor was clean / paint everything, replaced the seals and gaskets, and put in new pistons and rings. Everything else is stock.

Comment

-

can you take a pic of the top of the motor so maybe we can see something you might be missing. Sometime an extra pair of eyes helpMy stable

84 GSX1100EFG-10.62 @ 125 mph 64'' W/B.

85 GS1150-9.72@146mph stock W/B.

88 GSXR1100-dragbike 9.18@139.92mph/5.68@118mph.

98 Bandit 1200-9.38@146mph/6.02@121mph.

90 Suzuki GS 1425cc FBG Pro Stock chassis 5.42@124mph

06 GSXR750 10.44@135mph

00 Honda elite 80 pit bike

Comment

-

osterizer03

osterizer03 -

osterizer03

osterizer03

I tried to torque everything down both with and without the buckets over the valves. When I take the buckets out, there is no change.

Comment

-

osterizer03

osterizer03

Yup. The cams are only touching the journals when the buckets are out. As crazy or dumb as it sounds, I think making shims is the only option left....

Comment

-

Can you make your YouTube "public". It is currently listed as "private" so we can't see it.

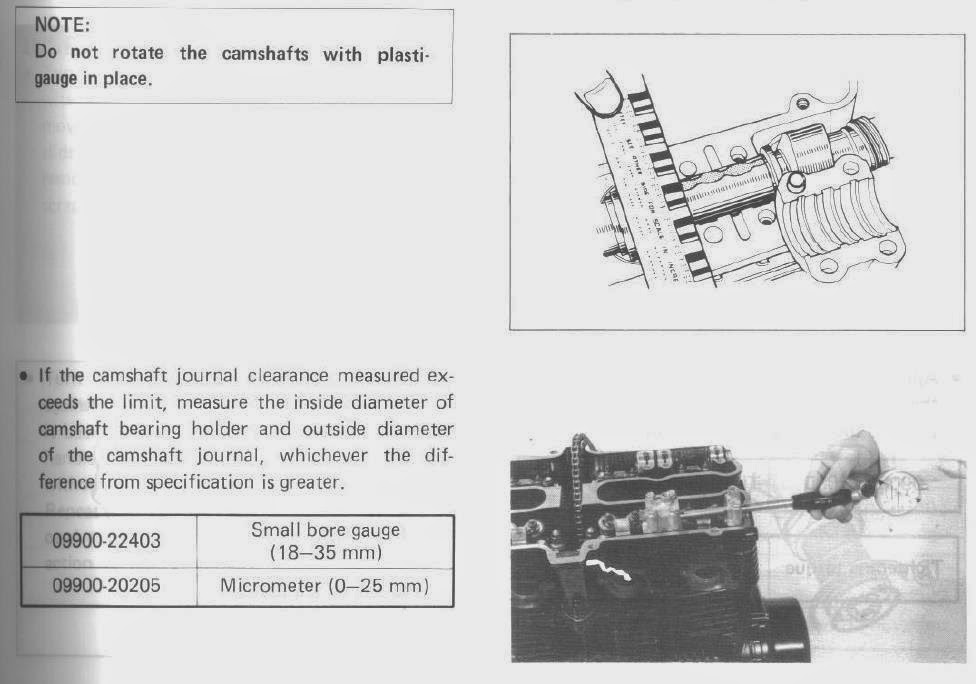

I read somewhere of an OCD engine builder that would set the cams in the saddles before attaching the cam chain and before any valves were installed. He would check to see that they spun nicely before assembling the rest of the motor. In my manual for the GS1150 there is a procedure for using Plastiguage or what we in UK know as Engineers Blue. This will show you where the high and low spots are:

Then, as it says, measure the outside of the cam journal and the inside of the saddles. Is there any difference?

Could also be cam run out (they are slightly bent).

I have never done it but there are threads here about lightly sanding down (you know with the highest grade wet and dry with water) the high spots on any saddles that are binding. You might try the Engineers Blue first and see if there are high and low spots.

Make sure you are using the correct torque settings. Use this converter if you are not sure:

GreetingsRichard

sigpic

GS1150 EF bought Jun 2015

GS1150 ES bought Mar 2014: ES Makeover Thread AND blog: Go to the Blog

GS1100 G (2) bought Aug 2013: Road Runner Project Thread AND blog: Go to the Blog

GS1100 G (1) Dad bought new 1985 (in rebuild) see: Dad's GS1100 G Rebuild AND blog: Go to the Blog

Previously owned: Suzuki GS750 EF (Canada), Suzuki GS750 (UK)(Avatar circa 1977), Yamaha XT500, Suzuki T500, Honda XL125, Garelli 50

Join the United Kingdom (UK) Suzuki GS Facebook Group here

Comment

-

osterizer03

osterizer03

Sorry about that. I've changed the video to public now. I will try the plastigage later tonight to see where I'm at. I've heard of people sanding the caps' base down to decrease the clearance but I need more material.

Comment

-

Sorry to say this but looks like you should do as Earl said a while back .pull the head and send it to a shop. If the cam is binding is it because your head is now warped? If so you will probably just blow a head gasket.Originally posted by osterizer03 View PostYup. The cams are only touching the journals when the buckets are out. As crazy or dumb as it sounds, I think making shims is the only option left....

I watched the video, did not realize that was such a small head. Same advice, pull the head and check the flatness of the compression surface. As strange as it may seem, by the way it binds on the last torque settings it looks like that head is warped. Since there are only two caps maybe a line bore will not be that much.Last edited by posplayr; 08-13-2014, 01:44 PM.

Comment

-

OK seen the video now.

I would oil up those bearings before tightening them down. The lubrication is what allows them to spin and they should never be allowed to get dry.

You say you need to "build them up". I don't understand why you need to build them up when they are too tight. Surely you need to sand them down to make the saddles and caps slightly larger?

Edit: I see what you mean now about sanding them down. I'm not talking about the bases, I'm talking about the round parts. Basically, boring them out a little using grit.

GreetingsLast edited by londonboards; 08-13-2014, 12:35 PM.Richard

sigpic

GS1150 EF bought Jun 2015

GS1150 ES bought Mar 2014: ES Makeover Thread AND blog: Go to the Blog

GS1100 G (2) bought Aug 2013: Road Runner Project Thread AND blog: Go to the Blog

GS1100 G (1) Dad bought new 1985 (in rebuild) see: Dad's GS1100 G Rebuild AND blog: Go to the Blog

Previously owned: Suzuki GS750 EF (Canada), Suzuki GS750 (UK)(Avatar circa 1977), Yamaha XT500, Suzuki T500, Honda XL125, Garelli 50

Join the United Kingdom (UK) Suzuki GS Facebook Group here

Comment

-

osterizer03

osterizer03

GregT, yes that's what I tried. Everything gets oiled up and cranked down to the proper 84 in lbs as the book calls for. I just tried this with the plastigage and found that I have absolutely no clearance. The book called out for 0.15mm clearance for the cams and the only readable one was 0.05mm BARELY. The rest just squished out and was not measurable. So now knowing this, Idk if it's the head that's warped because that should effect something that bolted down over a long, continuous plane. I'm bolting it down in only 2 spots and if this plastigage is showing fairly consistent "no clearance" readings, then something else might be causing this. The only thing I can think it might be is that when I used that 3M abrasive rubber bristle to clean up the gasket surface, I must have removed too much material. I tried to be SUPER carefull with it but any touching must be too much touching and now the caps clamp down too far. So it looks like either shims, or a new head and completely rebuild that one :/Last edited by Guest; 08-14-2014, 06:43 AM.

Comment

.png)

Comment