Valve Stem Seals, or maybe throw in the towel

Collapse

X

-

8 down- 8 to go. That went better than I had any right to think that it might.

Leave a comment:

-

All parts ordered, should be here before Xmas. I have vacation scheduled the whole last week of December. So with any luck I’ll be going for a New Years Day ride on a re-re-built GS. We’ll see how it goes. I may be able to get the valves back in the head this week.

I hate scraping gaskets, but at the same time find it very satisfying work. Complete focus on getting it all, and on not gouging the mating surface. Of course, after I took this picture, I dropped the razor blade down the cam chain tunnel. That really got me sweating til I eventually retrieved it with a small needle-nose pliers. I had a rag in the piston hole. No idea why I didn’t put one in the tunnel.

I had a rag in the piston hole. No idea why I didn’t put one in the tunnel.  But, with that, all parts are at least clean and ready for rebuild.

But, with that, all parts are at least clean and ready for rebuild.

Last edited by Rich82GS750TZ; 11-20-2023, 12:01 AM.

Last edited by Rich82GS750TZ; 11-20-2023, 12:01 AM.Leave a comment:

-

-

-

Utterly wrong - it's very easy to damage the lip that way and you won't know it until you've put it all back together and on the road.Leave a comment:

-

Lube is the best way to prevent seal lip damage. The valve stem end is beveled and collet retaining grooves are smooth and not sharp enough to damage the seal unless the seal is old, cold and hard. Best lube to use is molybdenum engine assembly grease. Factory manual says to use it. Assembly lube liquifies on start up and moly has strong anti-seize properties on metal on metal contact which is what you want until engine oil can reach where its needed. Stem seals wipe the valve stem but just enough oil is left on the stem to lubricate it. Just be gentle pushing the stem through the seal.Leave a comment:

-

I personally like to install the seals without the valves installed.

That way i have a better feel for the oiled up seal, i can feel the seal plop in the valve guide groove.

With better feel i mean compared to using pliers.

Remove the spring from the seal, oil the valve stem (GS valves do not have threads like in the movie shown earlier)

and push the valve through the seal.

No way that can cause damage to the lip.

Next, install the spring.

What's in this procedure that you find so risky ?

Last edited by Rijko; 11-01-2023, 04:48 PM.Leave a comment:

-

-

-

Conscious of the danger of damaging the seal lip, I inserted the valve into the head, covered the end of the stem with a bit of polythene that's long enough to cover the collet cut-out, then, with plenty of lube, slowly pushed the seal over the stem and down onto its seat. Not sure about your head, but mine has a seating recess at the base of the shoulder where the seal sits.

I used long cup-nosed pliers to seat the seals properly.

After that, easy enough to re-install the springs and collets.

<edit> pretty much like the video shows.

Frankly, anyone who advocates fitting the seal to the head, then just ramming the valve up through it, is an idiot whose advice on other stuff is probably just as flawed.Last edited by Grimly; 11-01-2023, 02:38 PM.Leave a comment:

-

Spring seats came out with out issue after some of the oil dried up a bit

Making slow progress over last few evenings. I lapped the valves. Got some Prussian blue dye and checked all. After a second go-round of lapping all valves and seats look more or less like the first pic below. First time doing this and learning. Pretty happy so far.

I have these seals in my eBay cart. Only ones I found that actually mention viton. I’ll get these unless someone has a better idea.

https://www.ebay.com/itm/300785685234?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=-nkPeINbTN2&sssrc=4429486&ssuid=EK7fcRW9Q5y&var=&wi dget_ver=artemis&media=COPY

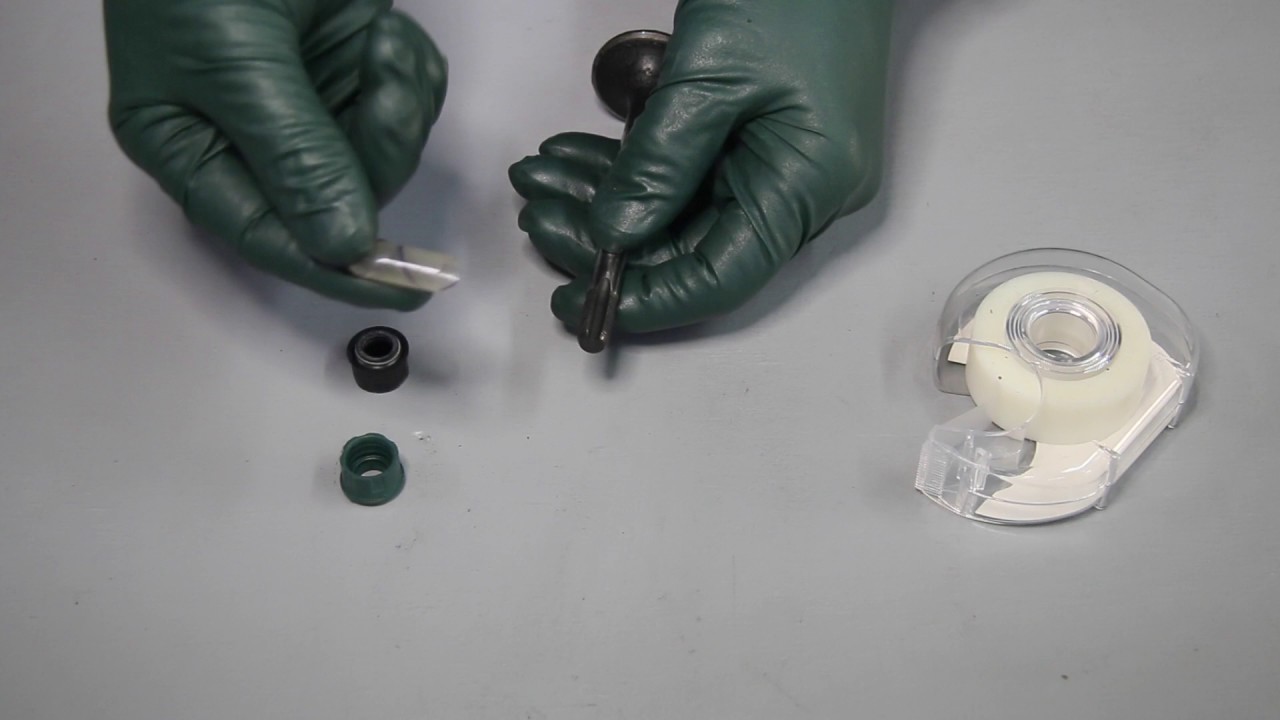

I have a question about installing the seals. Various videos show 2 different ways. Clymer manual says to push or drive the seals into place then insert the valve stems up through from the bottom through seat and seal. I’ve seen videos where they inset the stem through the seat first then install the seal over the stem. Is one way better? Does it matter. Dumb question?

edit: this seems like a good idea:

Anyway, thanks for the help. We’ll get there.

Last edited by Rich82GS750TZ; 10-31-2023, 08:40 PM.

Last edited by Rich82GS750TZ; 10-31-2023, 08:40 PM.Leave a comment:

-

You can lift the valve spring seats out without damage with a pair of pliers. There will be a film of oil underneath them that is sticking them in place. They aren't an interference fit.or anything like that.Leave a comment:

-

Thanks Ed. That’s a much better deal at $52.15 than the OEM head gasket, which partshark has for $90.44 I’ll be shopping for valve stem seals, base, head, valve cover, stator cover, clutch cover, and oil pan gaskets for this whole engine soon enough. Guess I know what to ask for for Christmas. Hmm, rebuild bits for the GS, or a top box for the Tiger.

I’ll be shopping for valve stem seals, base, head, valve cover, stator cover, clutch cover, and oil pan gaskets for this whole engine soon enough. Guess I know what to ask for for Christmas. Hmm, rebuild bits for the GS, or a top box for the Tiger. Last edited by Rich82GS750TZ; 10-19-2023, 05:13 PM.

Last edited by Rich82GS750TZ; 10-19-2023, 05:13 PM.Leave a comment:

Leave a comment: