Announcement

Collapse

No announcement yet.

16v 1000cc rebuild

Collapse

X

-

Smokinapankake

Smokinapankake

So I've found a place locally that builds lots o hot rods for that crowd; they have time and will test my springs tonite. Interesting to see how it all shakes down. Thanks Ray and Blowerbike for the words of advice; will let you know how it goes.Originally posted by rapidray View Post

-

Forum LongTimerGSResource Superstar

Past Site Supporter

Super Site Supporter- Mar 2006

- 35611

- Torrance, CA

I don't think there is much concern with running the stock springs unless you are going to run this bike super hard - high rpm on a regular basis. In most engine rebuild threads around here the people don't even bother to check the free height of the springs and I've yet to read about anyone bending valves due to float or other similar damage. Yes, checking spring pressure is ideal, but if the engine is stock and not some high mileage hack, I'd just throw it together and call it done. For anyone needing valve springs, I'd get stock although they are quite expensive so it's easy for me to say. I'll bet you a beer that those Ape and/or Kibblewite springs are a good 20% stiffer than stock, even the softer versions of the springs they sell, which is NOT needed or desired for use on a stock valve train. You want the lowest seat pressure necessary to keep the valve from floating to reduce cam/rocker/valve/seat wear and the stock springs are ideal. Keep it simple.Ed

To measure is to know.

Mikuni O-ring Kits For Sale...https://www.thegsresources.com/_foru...ts#post1703182

Top Newbie Mistakes thread...http://www.thegsresources.com/_forum...d.php?t=171846

Carb rebuild tutorial...https://gsarchive.bwringer.com/mtsac...d_Tutorial.pdf

KZ750E Rebuild Thread...http://www.thegsresources.com/_forum...0-Resurrection

Comment

-

Smokinapankake

Smokinapankake

Thanks Ed,

When I went down to Felts' Automotive (they have a machine shop that builds heads, etc...) and explained what I was after, the guy just kind of looked at me funny and asked me why I was even bothering. He pretty much said exactly what you said in that few people ever even bother to check free length, let alone tension at installed height. The people who do need to be especially concerned are those like Ray, who build for others and who dragrace, i.e., those who push their motors to the ragged edge. For a stocker with light service (like mine will be) he said just put 'er together and don't worry about it. He was quite impressed that I went to the trouble to measure free length and suggested that since they were: 1-reasonably well over the limit set in the factory manual; and 2-out of a well running engine before it got stripped apart they should be fine.

We had about a 45 minute conversation about it all; further discussion with my car drag racing buddy Tim and my other buddy Matt have allayed any fears I may have. And if I do bend a valve or ding a piston due to floating valves, so be it.

Thanks again for all the words of advice, I've learned alot. Once again GSR comes through.

Will post pictures after all is said and done.

Comment

-

smokinpankake,

i wish you the best of luck but your above comment is not correct in my opinion.

also an automotive place has no business even discussing motorcycle machine work.

Ed even knows better than to say..

well if it was ok before and you are going to race this bike ect ect ect.

the reason for checking is so that you know how your valve springs are and if they are shot to replace or at least shim the stock springs to get a tighter valve closing.

plus...

if you ever want to install a little larger cam(s) then things will be ok.

i choose to take customer heads to a "performance motorcycle" machine shop and have valve jobs..they also check the springs and shim or replace accordingly.

my post is about doing the right thing and not just "assuming" your seat pressure is ok.

when ever me or ray mentions a certain procedure..

its not always "racing" only.

listen and learn folks or cut corners and save a buck or three.

bust my balls if you want but my statement is 110% true.

i'll check back later so i can feel the love.

Comment

-

Forum LongTimerGSResource Superstar

Past Site Supporter

Super Site Supporter- Mar 2006

- 35611

- Torrance, CA

I found an excellent automotive machine shop that knows what they are doing so be careful painting with a broad brush like that.Originally posted by blowerbike View Postsmokinpankake,

i wish you the best of luck but your above comment is not correct in my opinion.

also an automotive place has no business even discussing motorcycle machine work.

Ed even knows better than to say..

well if it was ok before and you are going to race this bike ect ect ect.

the reason for checking is so that you know how your valve springs are and if they are shot to replace or at least shim the stock springs to get a tighter valve closing.

plus...

if you ever want to install a little larger cam(s) then things will be ok.

i choose to take customer heads to a "performance motorcycle" machine shop and have valve jobs..they also check the springs and shim or replace accordingly.

my post is about doing the right thing and not just "assuming" your seat pressure is ok.

when ever me or ray mentions a certain procedure..

its not always "racing" only.

listen and learn folks or cut corners and save a buck or three.

bust my balls if you want but my statement is 110% true.

i'll check back later so i can feel the love.

Regarding checking the spring pressure again, I think if you are taking someones money to do the work then checking the springs is the right thing to do. For my own bike though, and my advise for friends that won't be flogging the bike and racing, is to slam it together, again, assuming the springs are relatively low mileage and measure out okay.Ed

To measure is to know.

Mikuni O-ring Kits For Sale...https://www.thegsresources.com/_foru...ts#post1703182

Top Newbie Mistakes thread...http://www.thegsresources.com/_forum...d.php?t=171846

Carb rebuild tutorial...https://gsarchive.bwringer.com/mtsac...d_Tutorial.pdf

KZ750E Rebuild Thread...http://www.thegsresources.com/_forum...0-Resurrection

Comment

-

Smokinapankake

Smokinapankake

So my question is this:

If I'd never have taken this motor apart, which was running very well, my valve springs would be in an unknown condition, but the motor would be running well and not floating valves (because it never did before). I took it apart for the sole reason of making it easier to paint, and because it was weeping a smidge of oil at the base gasket.

Should we take every engine apart we ever get be it car or motorcycle or moped or jet ski or whatever just so we can measure the valve spring tension?

And not to be a smarta$$, but if the automotive shop has a spring tester that reads in the increments I need, (both length and kg or lb/ft or whatever) and the technician is competent in its usage, does it really matter if its a car shop vs. a performance motorcycle shop?

My buddies are coming over tonight. I'd like to get this motor together.

I see no real issue here aside from the thought that maybe we're overthinking it a little bit.

I'm not trying in any way to discredit you, Blower, or Ray. I've read many of your posts and they are intelligent, well thought out and obviously come from a background of experience, and I appreciate your input. I really do. I've learned alot these past few days, but I think I'm just going to put in my existing springs and hope for the best. If I bend a valve rolling around town well then I bend a valve. It would have happened had I not ever taken it apart, much like most other users on this forum have never and probably never will take their motors apart. If it's running well why would you?

It would be like removing the wheel, removing the tire to check the bead, and overhauling the wheel bearings just to put some air in the tire.

As always, thanks so much, and I'll be sure to post up pics of the whole ordeal!Last edited by Guest; 05-28-2010, 01:48 PM.

Comment

-

i could have swore that your head was off and the valves was out?????

i never said to take a "running" engine apart to do anything.

i said if its a part why not check the seat pressure and shim or replace the springs...the labor is the same....the heads already a part.

its like taking a clutch basket(large GS) a part to shim the springs...

the labor is the same to install an H/D backing plate.

just a few dollars for better parts and a piece of mind knowing that you have a better product.

as for the automotive machine shops go....

unless they have a motorcycle back ground then they have no idea what seat pressures or much of anything else concerning a GS motorcycle.

again,

please don't put words in my mouth.

i never said anything about taking a "running" bike/moped/jet ski ect.. a part to check the seat pressure.

good luck with your project.

Comment

-

Smokinapankake

Smokinapankake

Agreed, why would anyone ever take apart a good running motor?Originally posted by blowerbike View Posti could have swore that your head was off and the valves was out?????

i never said to take a "running" engine apart to do anything.

i said if its a part why not check the seat pressure and shim or replace the springs...the labor is the same....the heads already a part.

its like taking a clutch basket(large GS) a part to shim the springs...

the labor is the same to install an H/D backing plate.

just a few dollars for better parts and a piece of mind knowing that you have a better product.

as for the automotive machine shops go....

unless they have a motorcycle back ground then they have no idea what seat pressures or much of anything else concerning a GS motorcycle.

again,

please don't put words in my mouth.

i never said anything about taking a "running" bike/moped/jet ski ect.. a part to check the seat pressure.

good luck with your project.

But what I was trying to say is what is the problem with replacing my springs back into the same motor? It will be like I never took it apart in the first place, so why get all worked up about whether or not the springs are serviceable? They were before the motor came apart, they should be serviceable when I put it back together, right?

I understand wanting to know what condition everything is in, but didn't I already know that?

Not trying to put words in anybody's mouth; just trying to clarify my position. I'm getting the impression that I should just replace my springs because its apart when they don't necessarily need to be. Nobody said that explicity, but the impression is there.

Wouldn't the automotive shop ask what the service limits are? And if they didn't, wouldn't you tell them?

I plan to spend the rest of this motorcycle's life shuttling me back and forth to work with an occasional run up and down the highway to friend's houses..... No modding and hot rodding and cams and overbores or anything else. If I ever did that I would replace the valves and springs and whatever else to accomodate my end needs.

Thanks for the well wishes, I hope it all comes out ok too.Last edited by Guest; 05-28-2010, 02:39 PM.

Comment

-

Smokinapankake

Smokinapankake

As promised, photos of last nights progress:

Honing cylinders. Matt said he had a ball hone, and he did, but it was too big. So, since it was past closing time, we just went ahead and used my 3 stoner:

After hone:

Pistons with new rings installed:

Installing Pistons into cylinders:

Comment

-

Smokinapankake

Smokinapankake

Piston install continued - we didn't use any tools whatsoever, just our hands and they went in really nicely:

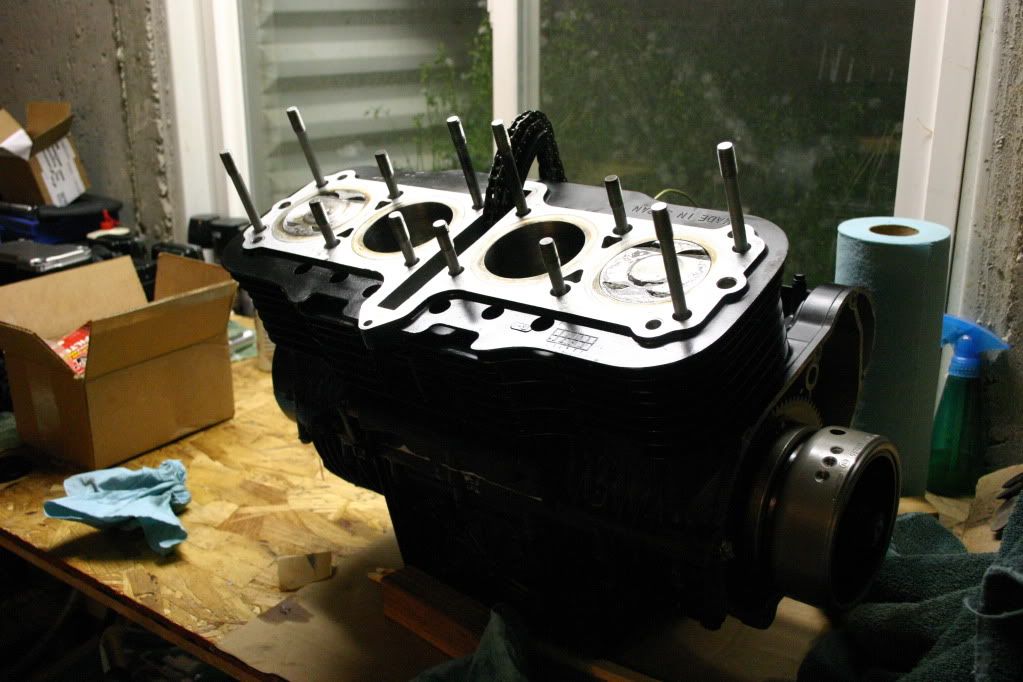

Cylinders install:

This is as far as we got. They were later in getting here, and Matt had to work in the morning, so we didn't get as far as I'd hoped we would. Oh well, there's always another day for that:

Still need to clean and lap valves and reassemble the head.

Comment

-

Forum LongTimerGSResource Superstar

Past Site Supporter

Super Site Supporter- Mar 2006

- 35611

- Torrance, CA

Sorry if this sounds critical but I don't like the look of that hone job. The hone marks need to be crisscross pattern - at 45 degrees. Also, I'm not a fan of heavy oil on the rings. Hope the hone is better than the photos show otherwise I'd pull the cylinder back off and get a proper ball hone in there.Ed

To measure is to know.

Mikuni O-ring Kits For Sale...https://www.thegsresources.com/_foru...ts#post1703182

Top Newbie Mistakes thread...http://www.thegsresources.com/_forum...d.php?t=171846

Carb rebuild tutorial...https://gsarchive.bwringer.com/mtsac...d_Tutorial.pdf

KZ750E Rebuild Thread...http://www.thegsresources.com/_forum...0-Resurrection

Comment

-

Turtleface

Turtleface

Originally posted by Nessism View PostSorry if this sounds critical but I don't like the look of that hone job. The hone marks need to be crisscross pattern - at 45 degrees. Also, I'm not a fan of heavy oil on the rings. Hope the hone is better than the photos show otherwise I'd pull the cylinder back off and get a proper ball hone in there.

I'm in agreement with Nessism, but all my engine building experience is with high performance small block Fords and Chevys, so take anything I have to say with a grain of salt. Always used a ball hone, and usually got pretty good results the first time around. I like to keep it moving up and down the bore fairly quickly, relative to the speed of the rotational movement of the hone. That 45 degree crosshatch pattern is fairly crucial to proper ring sealing during initial break-in.

Always used a ball hone, and usually got pretty good results the first time around. I like to keep it moving up and down the bore fairly quickly, relative to the speed of the rotational movement of the hone. That 45 degree crosshatch pattern is fairly crucial to proper ring sealing during initial break-in.

Comment

-

Smokinapankake

Smokinapankake

Ima pull it apart and do it again (hopefully Monday).

Didn't notice the hone isn't at more of a 45 degree crosshatch.

Comment

-

Forum LongTimerGSResource Superstar

Past Site Supporter

Super Site Supporter- Mar 2006

- 35611

- Torrance, CA

Bite the bullet and get a ball hone. You need to use a medium-slow drill and move it in and out quite quickly to get the proper 45 degree pattern. When doing this you should never allow the hone to stop while it's inside the cylinder. Also, don't hone any more than necessary to get the proper surface finish you need. A 240 grit hone is about right for our GS engines so don't get anything rougher than this.Originally posted by Smokinapankake View PostIma pull it apart and do it again (hopefully Monday).

Didn't notice the hone isn't at more of a 45 degree crosshatch.

Some good info here... http://www.enginehones.com/technical.htmlEd

To measure is to know.

Mikuni O-ring Kits For Sale...https://www.thegsresources.com/_foru...ts#post1703182

Top Newbie Mistakes thread...http://www.thegsresources.com/_forum...d.php?t=171846

Carb rebuild tutorial...https://gsarchive.bwringer.com/mtsac...d_Tutorial.pdf

KZ750E Rebuild Thread...http://www.thegsresources.com/_forum...0-Resurrection

Comment

.png)

Comment