I ordered the one that says it's for GS750, the 16x1.5 rh thread one. I go to thread it in, and it's too big. Anyone got any ideas? Could someone have swapped one off another bike? It does not have thread on the outside like the later model 1100's do. I'll try to get pictures for you guys later...

I ordered the one that says it's for GS750, the 16x1.5 rh thread one. I go to thread it in, and it's too big. Anyone got any ideas? Could someone have swapped one off another bike? It does not have thread on the outside like the later model 1100's do. I'll try to get pictures for you guys later...

Announcement

Collapse

No announcement yet.

Help with flywheel puller?

Collapse

X

-

Justonv

Justonv

Help with flywheel puller?

Well, I took offmy left side cover on my 81 GS750LX today planning on having a look at the starter clutch to see if it's the source of a mystery knock that developed at the end of last summer. The starter clutch has acted a little funny since I got it anyway, not always engaging, etc. I ordered my rotor puller from Z1, waited for it, go to use it today, and it doesn't fit I ordered the one that says it's for GS750, the 16x1.5 rh thread one. I go to thread it in, and it's too big. Anyone got any ideas? Could someone have swapped one off another bike? It does not have thread on the outside like the later model 1100's do. I'll try to get pictures for you guys later...

Last edited by Guest; 08-01-2010, 08:55 AM.Tags: None

I ordered the one that says it's for GS750, the 16x1.5 rh thread one. I go to thread it in, and it's too big. Anyone got any ideas? Could someone have swapped one off another bike? It does not have thread on the outside like the later model 1100's do. I'll try to get pictures for you guys later...

Last edited by Guest; 08-01-2010, 08:55 AM.Tags: None

-

I think a swingarm bolt is suppoded to work from your same bike.Originally posted by Justonv View PostWell, I took offmy left side cover on my 81 GS750LX today planning on having a look at the starter clutch to see if it's the source of a mystery knock that developed at the end of last summer. The starter clutch has acted a little funny since I got it anyway, not always engaging, etc. I ordered my rotor puller from Z1, waited for it, go to use it today, and it doesn't fit I ordered the one that says it's for GS750, the 16x1.5 rh thread one. I go to thread it in, and it's too big. Anyone got any ideas? Could someone have swapped one off another bike? It does not have thread on the outside like the later model 1100's do. I'll try to get pictures for you guys later...

I ordered the one that says it's for GS750, the 16x1.5 rh thread one. I go to thread it in, and it's too big. Anyone got any ideas? Could someone have swapped one off another bike? It does not have thread on the outside like the later model 1100's do. I'll try to get pictures for you guys later...

-

Suzuki_Don

Suzuki_Don

I think you will find it is 14 x 1.5mm, just buy a bolt of this size and weld a long shaft onto it with some kind of sliding weight so you can use it as a slide hammer to remove the rotor.Originally posted by Justonv View PostWell, I took offmy left side cover on my 81 GS750LX today planning on having a look at the starter clutch to see if it's the source of a mystery knock that developed at the end of last summer. The starter clutch has acted a little funny since I got it anyway, not always engaging, etc. I ordered my rotor puller from Z1, waited for it, go to use it today, and it doesn't fit I ordered the one that says it's for GS750, the 16x1.5 rh thread one. I go to thread it in, and it's too big. Anyone got any ideas? Could someone have swapped one off another bike? It does not have thread on the outside like the later model 1100's do. I'll try to get pictures for you guys later...

I ordered the one that says it's for GS750, the 16x1.5 rh thread one. I go to thread it in, and it's too big. Anyone got any ideas? Could someone have swapped one off another bike? It does not have thread on the outside like the later model 1100's do. I'll try to get pictures for you guys later...

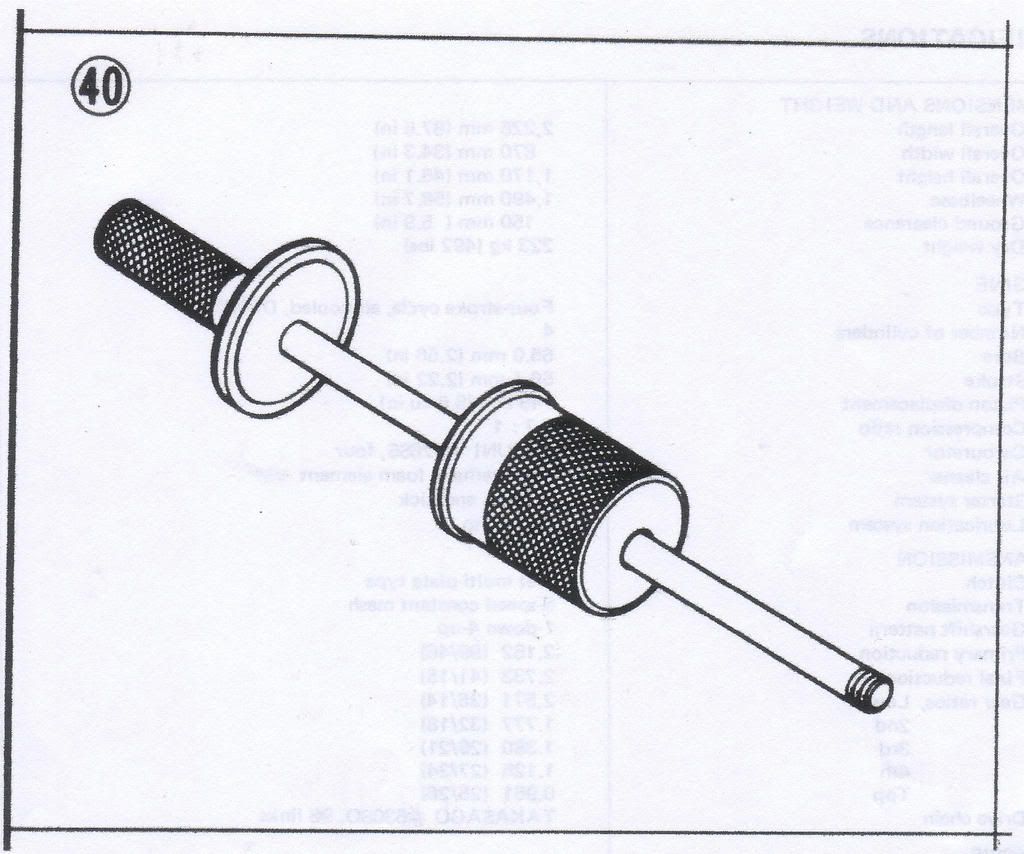

THE SUZUKI TOOL:

MY TOOL:

Good luck

Comment

-

Justonv

Justonv

Thank you Don, that's exactly what I was going to do, but then I found the other tool for only 10 bucks and though, eh, why mess with it. Apparently because it doesn't work, haha. Why is it that these are a different size than what they are supposed to be? Anyone know?

Comment

-

Hey there is even a grease trick if you do a search and search and search........................

Apparently IIRC, when you put grease under the end of the bolt (in the hole), as you tighten the bolt the grease transfers a force from the head of the bolt to the end of the crank and the rotor pops right off.

My GS750 rotor almost just fell off as it was not anywhere near as stuck as a GS1100E rotor.

Comment

-

you can use the same trick on a pilot bearing in the end of a car crank shaft.Originally posted by posplayr View PostHey there is even a grease trick if you do a search and search and search........................

Apparently IIRC, when you put grease under the end of the bolt (in the hole), as you tighten the bolt the grease transfers a force from the head of the bolt to the end of the crank and the rotor pops right off.

My GS750 rotor almost just fell off as it was not anywhere near as stuck as a GS1100E rotor.

i believe its a hydraulic kinda thing..can't compress the grease ect.. when dealing with a "bottom hole".

Comment

-

I was afraid to read on Don when you stated you had posted a picture of your tool. 1983 GS 1100E w/ 1230 kit, .340 lift Web Cams, Ape heavy duty valve springs, 83 1100 head with 1.5mm oversized SS intake valves, 1150 crank, Vance and Hines 1150 SuperHub, Star Racing high volume oil pump gears, 36mm carebs Dynojet stage 3 jet kit, Posplayr's SSPB, Progressive rear shocks and fork springs, Dyna 2000, Dynatek green coils and Vance & Hines 4-1 exhaust.

1983 GS 1100E w/ 1230 kit, .340 lift Web Cams, Ape heavy duty valve springs, 83 1100 head with 1.5mm oversized SS intake valves, 1150 crank, Vance and Hines 1150 SuperHub, Star Racing high volume oil pump gears, 36mm carebs Dynojet stage 3 jet kit, Posplayr's SSPB, Progressive rear shocks and fork springs, Dyna 2000, Dynatek green coils and Vance & Hines 4-1 exhaust.

1985 GS1150ES stock with 85 Red E bodywork.

Comment

-

Suzuki_Don

Suzuki_Don

I'm not shy, you know that Bill.Originally posted by chef1366 View PostI was afraid to read on Don when you stated you had posted a picture of your tool.

Blower, the reason that your idea would not work in my case was that the taper on the end of the shaft had been Loctited in place and took a lot of effort to remove it. Even with the slide hammer it would not come off. I had to hit the hammer head on the long bolt with a 2lb lump hammer and it eventually came off on the third hit. I tried your idea and it would not budge. Besides it is only a 5 min. effort to make this tool if you have a welder.

Comment

-

rkubik

rkubik

want to sell it?

I am just in the process of ordering that very one, the 16 x 1.5 RH puller. Check your PM, or please reply here! Thx.

R

Comment

-

Justonv

Justonv

Well, here is what I ended up doing. After hunting around town with no success for a 14x1.5 bolt, I remembered that was the size of the lug studs on my pickup. So, I went and knocked a lug out of an extra rear end I have, cleaned it up good on the wire wheel and went to check and make sure it threaded. Perfect. Then I went and found an old weight bar that had been in our junk pile, and it was fabrication time. Fired up the old lincoln welder (welds much better than the wire welder) and went to town. Here's what I came out with, (I know, the welds are a little bit ugly, but my dad is the pro welder, leaves me without much opportunity to practice ) lol I'm working on it though!

) lol I'm working on it though!

Comment

-

Justonv

Justonv

Oh yeah, lol, this is what I found when I got it off. First off, you will notice the two cracks in the starter clutch... not normal, right? Secondly, when I was pulling it apart, I pulled out the 3 bolts that bolt it to the flywheel, and to my surprise, they were all 3 covered in a very coarse, whitish sand. Holes had it in there, all 3 bolts covered. So, I cleaned it all up good. I haven't found this anywhere else on the bike, or in the oil anytime I've changed it, so I have no clue what to make of this. Also, the first time I pulled out the main bolt, it was fairly loose, and apparently my flywheel had slipped a little at one time, as the crank has a slight groove in it, with a corresponding burr on the flywheel.

Anybody got any suggestions on where to come up with a new starter clutch? I'm on a very tight budget right now, so if I have to order a new one, it will probably be this winter before I get to do it. I guess if that's what I have to do, it's not that big a deal, but I would love to get to ride my bike a bit! haha

Comment

-

i'm still not sure why a person would make a slide hammer when a bolt and a torch would do the job...Originally posted by Justonv View PostOh yeah, lol, this is what I found when I got it off. First off, you will notice the two cracks in the starter clutch... not normal, right? Secondly, when I was pulling it apart, I pulled out the 3 bolts that bolt it to the flywheel, and to my surprise, they were all 3 covered in a very coarse, whitish sand. Holes had it in there, all 3 bolts covered. So, I cleaned it all up good. I haven't found this anywhere else on the bike, or in the oil anytime I've changed it, so I have no clue what to make of this. Also, the first time I pulled out the main bolt, it was fairly loose, and apparently my flywheel had slipped a little at one time, as the crank has a slight groove in it, with a corresponding burr on the flywheel.

Anybody got any suggestions on where to come up with a new starter clutch? I'm on a very tight budget right now, so if I have to order a new one, it will probably be this winter before I get to do it. I guess if that's what I have to do, it's not that big a deal, but I would love to get to ride my bike a bit! haha

but to answer your question on parts location.....

PM TCK/josh...i believe he has a complete assembly..

Comment

.png)

Comment