Before you fit up the replacement hub, use a fine flat file to smooth out any ridges that the clutch plate tabs have left behind. Your old one has some pretty deep ridges, which make the clutch operation not as free.

Announcement

Collapse

No announcement yet.

Camshaft Top End Rattle

Collapse

X

-

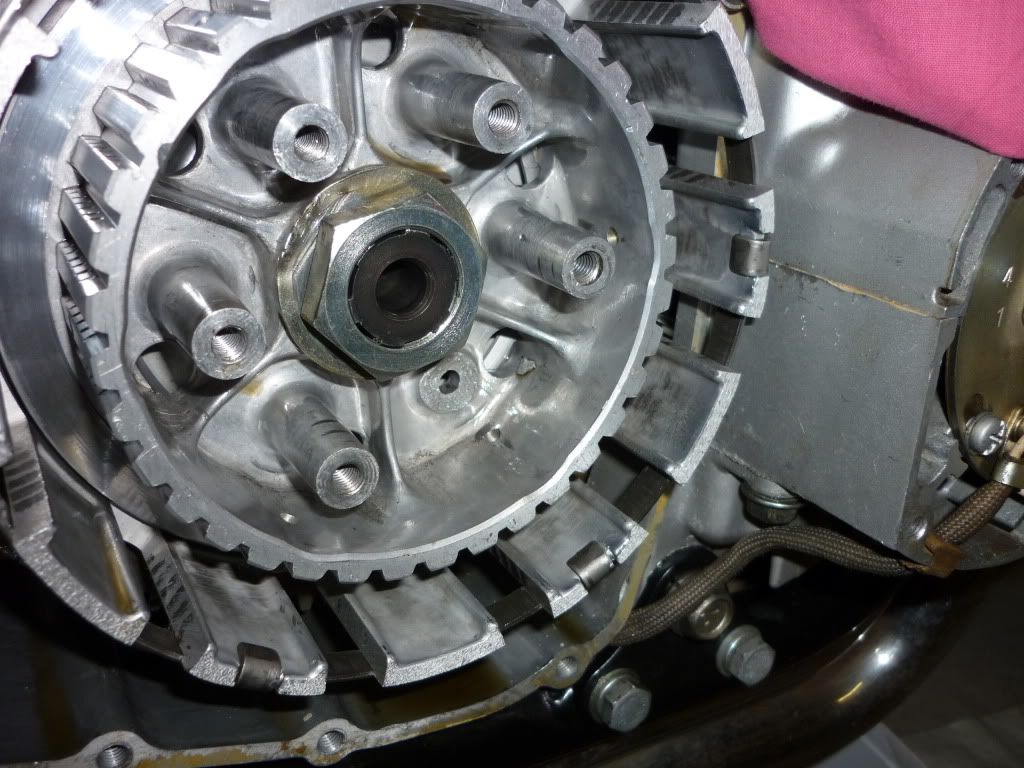

Don, that hubs a mess alright.Originally posted by Suzuki_Don View Post

Before you fit up the replacement hub, use a fine flat file to smooth out any ridges that the clutch plate tabs have left behind. Your old one has some pretty deep ridges, which make the clutch operation not as free.:) The road to hell is paved with good intentions......................................

GS 850GN JE 894 10.5-1 pistons, Barnett Clutch, C-W 4-1, B-B MPD Ignition, Progressive suspension, Sport Demons. Sold

GS 850GT JE 1023 11-1 pistons. Sold

GS1150ES3 stock, V&H 4-1. Sold

GS1100GD, future resto project. Sold

http://i155.photobucket.com/albums/s...s/P1000001.jpg

http://i155.photobucket.com/albums/s...s/P1000581.jpg

-

Suzuki_Don

Suzuki_Don

Thanks Ian, will do. It's a funny thing that when the clutch is playing up because of ridges in the hub, etc. lack of free movement of the clutch plates when the lever is pulled in, it is always in the lower gears that it shows itself. 4th, 5th & 6th change alright but the lower gears particularly 1st & 2nd are very notchy and at times hard to get out of gear when changing gears.Originally posted by 49er View PostDon, that hubs a mess alright.

Before you fit up the replacement hub, use a fine flat file to smooth out any ridges that the clutch plate tabs have left behind. Your old one has some pretty deep ridges, which make the clutch operation not as free.

The new EBC fibre plates I am using seem to be a tight fit where the tongues fit into the clutch basket. In fact It took a bit of effort and wiggling to get them to fit in the corresponding slots in the basket. I was wondering if tightness here causing binding would cause the clutch to cause notchiness in the lower gears that i have been experiencing since I fitted the new EBC plates.

I will measure the width of the tongues on the old clutch plates and compare with the EBC plates to see if there is any difference and dress the tongues with a file to give more clearance if necessary.

What do you think.

Comment

-

That's a bit of a bugger Don but at least you found it! Did you try to get a new basket here at all? I would imagine they're hard to find and expensive if you can...Originally posted by Suzuki_Don View PostThis will probably explain my clutch and gear changing problems the other day.

I took the clutch apart, when the pressure plate came off these parts fell into my hands.

You can see where one of the clutch spigots broke away from the clutch hub. When I inspected the part I could see half of the broken surface was old (previous break) and the other portion was new. There was a definite demarcation between earlier fracture and the later one.

I am now waiting on a used part to arrive from the USA before I can reassemble the clutch, but have plenty of other stuff to go on with, changing a few shims, dressing the clutch plate tabs, etc.1982 GS450E - The Wee Beastie

1984 GSX750S Katana 7/11 - Kit Kat - BOTM May 2020

sigpic

450 Refresh thread: https://www.thegsresources.com/_foru...-GS450-Refresh

Katana 7/11 thread: http://www.thegsresources.com/_forum...84-Katana-7-11

Comment

-

Forum LongTimerGSResource Superstar

Past Site Supporter

Super Site Supporter- Oct 2006

- 14217

- London, UK to Redondo Beach, California

Manual quotes a wear limit for those tongues if I remember correctly.

+1 on the Avons. The cracking was a rogue batch. You can use them with tubes. I do on my skunk. Any new tyre will work with a tube if necessary in my experience. They usually say "use tube on tube type rim" or something on the sidewall.

120 is perfect for your rear, 130 is good on the 2.5.1980 GS1000G - Sold

1978 GS1000E - Finished!

1980 GS550E - Fixed & given to a friend

1983 GS750ES Special - Sold

2009 KLR 650 - Sold - gone to TX!

1982 GS1100G - Rebuilt and finished. - Sold

2009 TE610 - Dual Sporting around dreaming of Dakar..... - FOR SALE!

www.parasiticsanalytics.com

TWINPOT BRAKE UPGRADE LINKY: http://www.thegsresources.com/_forum...e-on-78-Skunk/

Comment

-

Yeah, I'd file those tongues until they move freely and you should be good to go. I hope those spring mounts don't make a habit of breaking!Originally posted by Suzuki_Don View PostThanks Ian, will do. It's a funny thing that when the clutch is playing up because of ridges in the hub, etc. lack of free movement of the clutch plates when the lever is pulled in, it is always in the lower gears that it shows itself. 4th, 5th & 6th change alright but the lower gears particularly 1st & 2nd are very notchy and at times hard to get out of gear when changing gears.

The new EBC fibre plates I am using seem to be a tight fit where the tongues fit into the clutch basket. In fact It took a bit of effort and wiggling to get them to fit in the corresponding slots in the basket. I was wondering if tightness here causing binding would cause the clutch to cause notchiness in the lower gears that i have been experiencing since I fitted the new EBC plates.

I will measure the width of the tongues on the old clutch plates and compare with the EBC plates to see if there is any difference and dress the tongues with a file to give more clearance if necessary.

What do you think.:) The road to hell is paved with good intentions......................................

GS 850GN JE 894 10.5-1 pistons, Barnett Clutch, C-W 4-1, B-B MPD Ignition, Progressive suspension, Sport Demons. Sold

GS 850GT JE 1023 11-1 pistons. Sold

GS1150ES3 stock, V&H 4-1. Sold

GS1100GD, future resto project. Sold

http://i155.photobucket.com/albums/s...s/P1000001.jpg

http://i155.photobucket.com/albums/s...s/P1000581.jpg

Comment

-

mlinder

mlinder

Just for future reference for anyone else doing this, Dons needing to use a thicker base gasket is not an anomaly.

I too will need to cut a base gasket to get the shoulders of the pistons about flush with deck, which will give somewhere around .040 squish clearance.

I'm a little surprised at just how easy this is turning out, though. Generally speaking, a 50% bump in power costs a lot more and requires a lot more work.

Comment

-

Suzuki_Don

Suzuki_Don

And you'll be very pleased with the end result. Good luck with it Mark.Originally posted by mlinder View PostJust for future reference for anyone else doing this, Dons needing to use a thicker base gasket is not an anomaly.

I too will need to cut a base gasket to get the shoulders of the pistons about flush with deck, which will give somewhere around .040 squish clearance.

I'm a little surprised at just how easy this is turning out, though. Generally speaking, a 50% bump in power costs a lot more and requires a lot more work.

Comment

-

mlinder

mlinder

I'm sure I will, Don.

I'm excited to tell you about the upcoming project that will eventually be going on this 550 bottom end.

Comment

-

janner

janner

Suzuki Don, I read you thread from end to end as it sounded like the same rattle as mine, listening to your final video , your tickover was quite high so disguising the noise somewhat, but ! listening to the first video , your noise was conatant whereas mine is more clack,clack,clack...........clack,clack,clack on tickover, it was a brilliant thread and had me hanging on till the bitter end hoping that you found the cause, it does sound much better now with the carb sync, but do you think it was more cltch related???, cant wait to sync my carbs now to hope mine inproves, it is a bloody annoying rattle though thats driving me mad...

Comment

-

Suzuki_Don

Suzuki_Don

Final solution

I've been a bit slack in closing this thread off. So here goes.

After I replaced the inner clutch hub which I purchased used from the States, I then purchased the outer clutch basket from the same business as he'd given me excellent service, and a good price on the item and freight on the previous purchase.

I had purchased the used basket so I could remove mine and do the clutch basket modification by stacking the springs with hardened washers and rewelding the back of the clutch basket.

I replaced my old basket with the other one I purchased from the States. I also found that the EBC clutch fibre plates were too wide on the tongues/tangs that fit into the slots in the outer basket. So I filed these tangs down on one side only to the specifications hilited by Dan in my Suzuki manual.

The trick here is to file down the side of the tang that does not take up on the basket slot when the drive is applied. So there is still a nice square shoulder/surface to bear against the basket slot as the drive is taken up. Do the filing on the other side of the tang to provide enough clearance for the plates to slide freely when activating the clutch.

Doing this modification eliminated the problem I mentioned earlier where I had trouble shifting in the lower gears when coming to a stop.

Anyway when it was all back together with new/2nd hand centre clutch hub, clutch outer basket and clutch fibre plates filed down appropriately the bike shifted gears beautifully up and down the range, neutral was easy to find when stopped, etc.

Also the rattling noise has disappeared from the motor completely. In fact other riders now comment on how quiet my motor is. A friend on his Duke ST3 this last weekend made that exact comment. BTW you should hear the noisy clutch on his bike, it makes a real racket, he said the clutch on his Ducati runs dry and is vented to the atmosphere with many slots in the clutch cover and this is the reason for the noise. He said all Dukes are like that. It was news to me. Oh well I'll keep my Suzuki if that's the case.

So it turns out that the clutch basket that replaced my original one was obviously in much better condition internally and the rattle was obviously coming from my old basket at idle. Now everything is quiet and operating as it should I have not even given another thought to having the modification done to my original clutch basket. That can wait until the motor starts to rattle again. Hopefully never.

So the long and the short of it is I did not need to strip the motor the second time to look for this rattle, all I needed to do was replace the clutch basket and all would have been well.

If nothing else I had a chance to become more conversant with another total stripdown of the motor. Right down to the cases split, crankshaft and transmission shafts out, and another rebuild. Only this time it only took two weeks to strip and rebuild it compared with eight months the first time (I did have a lot of breaks in between to do other things though).

Comment

.png)

Wil give (some)* details as soon as it starts.

Wil give (some)* details as soon as it starts.

Comment