Announcement

Collapse

No announcement yet.

clutch play

Collapse

X

-

clutch play

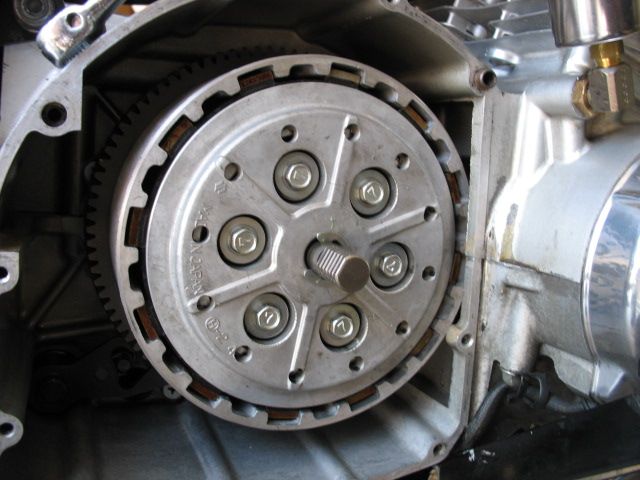

Ok, so today I went ahead and installed a heavy duty clutch hub nut on my 1100. Prior to this I had noticed a lot of physical shaking at idle with the clutch lever out, not just noise. The clutch springs are nice and tight and so is the basket. The hub nut was not loose. When I went to put the new bolt on I noticed there was a lot of in and out play in the clutch basket if you pull and push on it. That cant be normal right?, it almost feels like there is a spacer missing or something but it was all put back together right according to various sources.Tags: None

-

What year? Some of the later models 82-83 1100s sixteen valve have different size shims (washers) under the clutch basket.

I have a little play but I don't know how much you have.1983 GS 1100E w/ 1230 kit, .340 lift Web Cams, Ape heavy duty valve springs, 83 1100 head with 1.5mm oversized SS intake valves, 1150 crank, Vance and Hines 1150 SuperHub, Star Racing high volume oil pump gears, 36mm carebs Dynojet stage 3 jet kit, Posplayr's SSPB, Progressive rear shocks and fork springs, Dyna 2000, Dynatek green coils and Vance & Hines 4-1 exhaust.

1985 GS1150ES stock with 85 Red E bodywork.

-

evan132

evan132

Its an 83, I should probably put that in my sig. Anyway, I would say its about a 16th of an inch. That shim is in there, at least it was when I put it together last year . There was some play then but I only noticed the little side to side movent which I figured was normal.

. There was some play then but I only noticed the little side to side movent which I figured was normal.

Comment

-

evan132

evan132 -

5150/gs

5150/gs -

5150/gs

5150/gs -

zuzu

zuzu

Bump.

I am also interested in how much play there should be in the clutch hub. I just removed the HD springs that were installed back in 1984 and noticed some minimal play in the clutch hub and backing plate. The rivets were welded back when the engine was built. About 13,000 mile ago. The only noise I hear is when you remove the oil filler cap. Then you can hear a rattling, gets better when the clutch lever is pulled in.

Comment

-

To measure the thrust clearance properly I have been instructed to take out the complete clutch basket, pump gears etc.and stack the oil pump gear, clutch basket and the large spacer with the needle bearing on it on a flat surface then install the large washer with the groove in it that faces towards the basket and take a feeler gauge and measure the clearance between the clutch basket and the large washer. Clearance should be .002 to .003 max if I remember correctly. If clearances are tight then install shims as needed. The last one I did a while back required me to take the large center spacer to a machine shop and have in milled a few thousandths to bring it down within specs. With the helical cut gear thrust clearance is critical in keeping the clutch from creeping when revved up, excessive noise when it gets thrust back and forth inwards and outwards, therefore GS's needing the hardened nut in preventing it from being pushed off due to excessive clearance, high horsepower,or even just hard off and on acceleration. Hopefully this might help you some. I would like to hear any other input on this since this is how Greg Cope back when he was crew chief for Dave Schultz discussed this with me years ago. sigpic 82 gs1100ez 1168 Wiseco,Web .348 Cams,Falicon Sprockets,Star Racing Ported Head,1mm o/s Stainless Valves,APE Springs,Bronze Guides,etc.APE Billet Tensioner,36CV Carbs,Stage 3 Dynojet,Plenum w/K&N filter,Trued,Welded,Balanced,Crank w/Katana rods & Billet left end, FBG backcut trans, VHR HD Clutch basket,APE nut,VHR High volume oil pump gears,1150 Oil cooler,V&H Megaphone header w/Competition baffle,Dyna S,Coils,Wires,etc.Other misc.mods.

sigpic 82 gs1100ez 1168 Wiseco,Web .348 Cams,Falicon Sprockets,Star Racing Ported Head,1mm o/s Stainless Valves,APE Springs,Bronze Guides,etc.APE Billet Tensioner,36CV Carbs,Stage 3 Dynojet,Plenum w/K&N filter,Trued,Welded,Balanced,Crank w/Katana rods & Billet left end, FBG backcut trans, VHR HD Clutch basket,APE nut,VHR High volume oil pump gears,1150 Oil cooler,V&H Megaphone header w/Competition baffle,Dyna S,Coils,Wires,etc.Other misc.mods.

Comment

-

zuzu

zuzu

I finally got my clutch torn down and I measured has you posted. I am coming up with about .006 as its a bit hard to measure inside the basket.Originally posted by gs11ezrydr View PostTo measure the thrust clearance properly I have been instructed to take out the complete clutch basket, pump gears etc.and stack the oil pump gear, clutch basket and the large spacer with the needle bearing on it on a flat surface then install the large washer with the groove in it that faces towards the basket and take a feeler gauge and measure the clearance between the clutch basket and the large washer. Clearance should be .002 to .003 max if I remember correctly. If clearances are tight then install shims as needed. The last one I did a while back required me to take the large center spacer to a machine shop and have in milled a few thousandths to bring it down within specs. With the helical cut gear thrust clearance is critical in keeping the clutch from creeping when revved up, excessive noise when it gets thrust back and forth inwards and outwards, therefore GS's needing the hardened nut in preventing it from being pushed off due to excessive clearance, high horsepower,or even just hard off and on acceleration. Hopefully this might help you some. I would like to hear any other input on this since this is how Greg Cope back when he was crew chief for Dave Schultz discussed this with me years ago.

Your are saying that I need to have the large spacer where the needle bearing resides machined down so I only have about .001 .002 clearance ?

Thanks

Comment

-

zuzu

zuzu

Update

I sent my Clutch Hub to APE to get the HD backing plate and springs installed. I also have new hub bearings coming. When I get everything back I will remeasure and see what thrust clearance is. The clutch is in very good condition. The fibers measure around 3.1 mm and the steel plates also measure within specs and look like new.

We have a bunch of nice weather coming up at the end of this week. I hope I can get it back together by the weekend.

I prefer to ride my Gs over this,

Last edited by Guest; 06-24-2013, 10:24 PM.

Last edited by Guest; 06-24-2013, 10:24 PM.

Comment

-

zuzu

zuzu

I got my clutch hub back from APE today. They sure did a great job installing the H/D backing plate and springs. I had ordered a new hub bearing along with the six aluminum spacers that go inside the clutch springs. I also installed three H/D clutch springs and three OEM springs and a heavy duty hub nut.

I got the hub and clutch pack in. All parts were new or well within specs. I still had a small amount of side to side play and end play. I believe this to be normal so I buttoned up the job.

The clutch is butter smooth and all the rattling is gone. The clutch lever pull is just right.

Comment

.png)

Comment