Dodgy torque wrench or dodgy bolt?

Announcement

Collapse

No announcement yet.

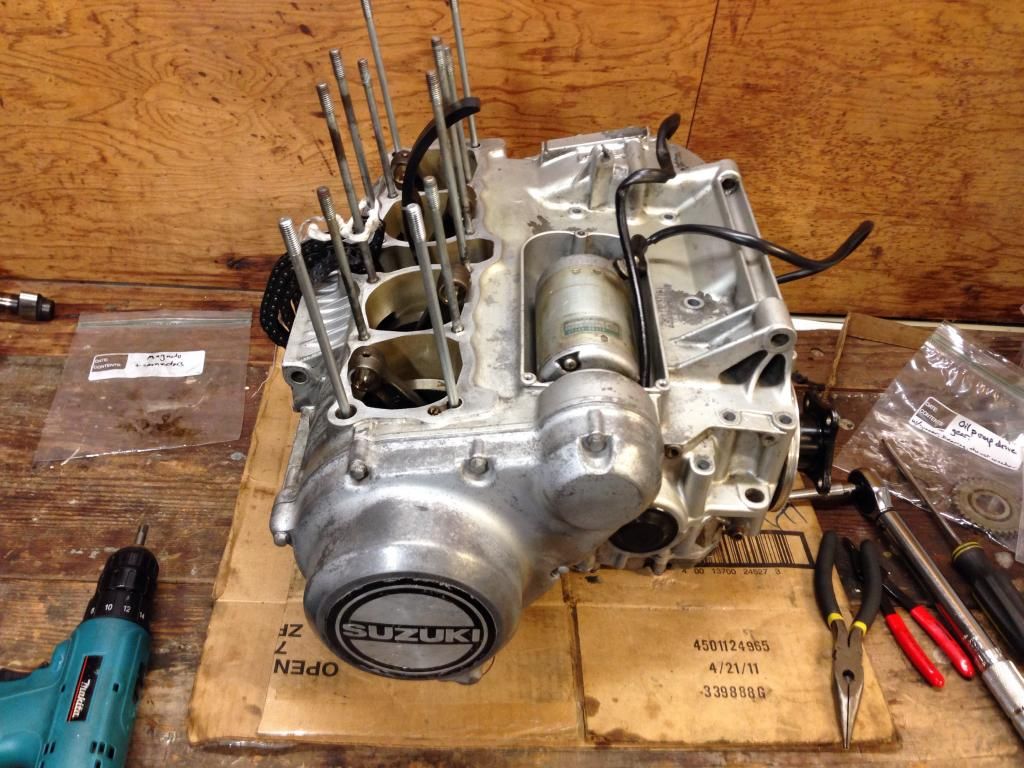

1982 GS650GL. 2nd gear is busted. Time to take apart the engine

Collapse

X

-

William Groebe

William Groebe

eil - It's a new torque wrench, so I'd like to say it's a dodgy bolt, but maybe the wrench is too new. I haven't gotten the feel for it yet.

60ratrod - The manual doesn't say anything about putting anti-seize on the bolts, so I was not planning on using any, but I'm open to suggestions. I just want to stay as close to the "standard operating procedure" as possible. I'm new to this, so I don't want to stray too far or I'm liable to get lost.

Comment

-

barnbiketom

barnbiketom -

60ratrod

60ratrod

anti-sieze is just a good measure to make sure that you don't have this problem in the future. it's worse with stainless steel fasteners. the corrosion reaction is so intense that it happens quickly when moisture is introduced and it's bad. we had a jet on deployment that had a stainless steel patch put in way before we got it and it corroded a huge hole. antiseize is just a good precautionary measure to minimize the dissimilar metals corrosion. i'm guessing that was part of what happened with that bolt

Comment

-

William Groebe

William Groebe

Comment

-

William Groebe

William Groebe

Ok, so I went ahead and attempted to put the cases together again tonight. I'd bought a replacement 6mm bolt for the one that had snapped. I put a little anti-seize on each bolt to help fight future corrosion. Threebond on the mating surfaces. Everything is going as planned. I'm being extra careful torquing down the bolts when CRACK! Another one of the 6mm bolts snapped. This time I was very careful and had not only rotated the wrench slowly and carefully, but had set the initial torque value to 3ft-lb instead of 4.5. It's the damn bolts! Apparently the 6mm bolts have just corroded over time. I'm lucky I was able to get them off in one piece in the first place. Tomorrow I'm going to the autoparts store and I'm going to buy all new 6mm bolts for the case. This is getting ridiculous.

Oh well. Taking it apart again for cleaning and prepping for another go tomorrow... again.

Comment

-

barnbiketom

barnbiketom

I would really try another torque wrench...Ideally you need a 1/4" with 0-50 inchpounds. or zero-100 inchpounds. simply convert the 3 ( or whatever the correct torque) is by multiplying by 12..... 3 ft./lbs. = 36 inchpounds !!!

If you are using a 3/8" or worse yet, a 1/2" torque wrench..you will never get it correct because the reading is so negligible it may be WAAY OFF. if you are using a large torque wrench and trying to use it on the LOWER part of the scale, thats where it will be most incorrect. and I suspect thats why you are snapping bolts, rather than them being bad.

always, on any measuring device, the mid to 3/4 range of the device is the most accurate, not the lowest portion.

at least I would check that wrench against another good one for future knowledge!!!!

forgive me if you are already using a small wrench, i just wanna make sure!!!!Last edited by Guest; 09-18-2014, 11:25 AM.

Comment

-

William Groebe

William Groebe

barnbiketom - I'll go get an inchpound wrench today. I am using a large footpound wrench, and I didn't know about the readings being way off at the lower end.

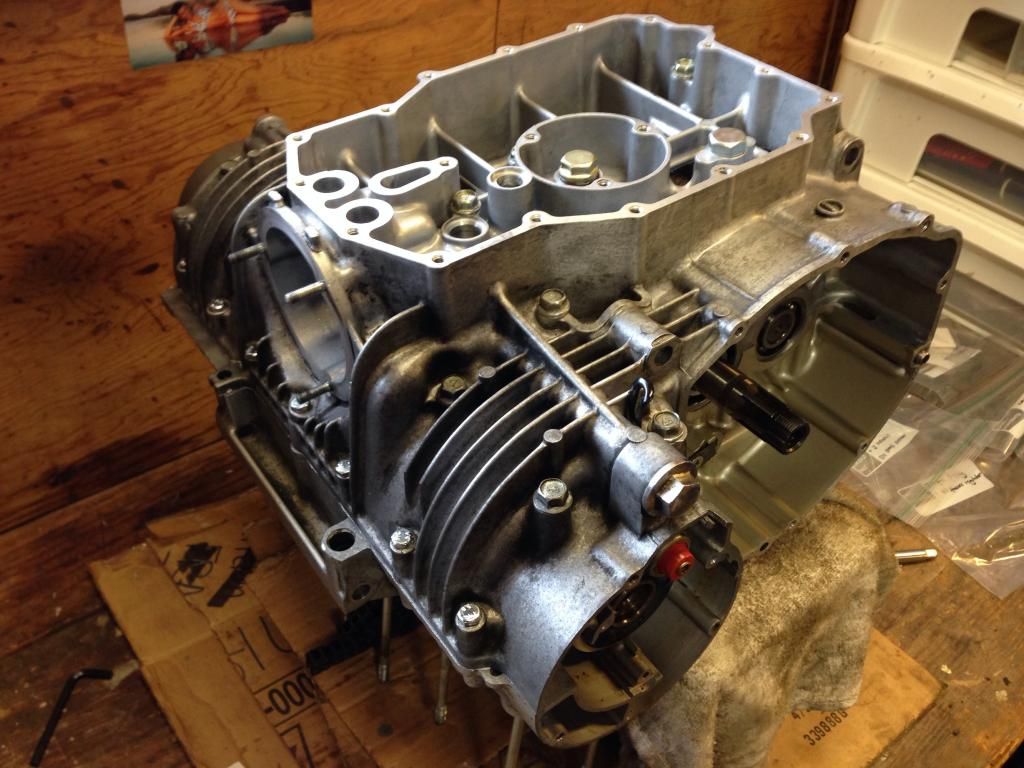

But on a better note. I did get the cases together this morning before heading off to work. Went to the autoparts store first thing in the morning, got the new 6mm bolts, went home, torqued everything down slowly and it all worked great. Can't wait to get back home tonight and see how far I can get putting everything back together.

Of course with all the trouble I've been going through I bet that after I get the bike all together I'll take it out for its first ride and there will be a Bellagio fountain of oil leaks spraying out of my engine. Well, that will be for another day. For now, it's reconstruction time.

Comment

-

William Groebe

William Groebe

Alright.

Thanks to barnbiketom for explaining torque wrenches for me. Nowhere on the 5-80ft-lb wrench packaging does it say 'this doesn't actually accurately work for 5ft-lbs. I bought myself an in-lb wrench today after work.

I'm making some good progress. If all goes well I may be riding to work on Monday.

Comment

-

barnbiketom

barnbiketom

lookin good! after re-looking at you pics, I think my 650L's whine may be normal.. there's a few things in there that might be the source but I've just accepted the noise for now, and it's for sale anyway hahah. Good work.. you can work on my engine Anytime!!

Comment

-

60ratrod

60ratrod

i kinda agree with barnbike and thinking about the vibration you talk about. my 650g does the same thing. it don't bother me that much. it is coming together nicely. i'll be tearing into mine after i'm done tinkering with my kz1000m1. i'm trying to salvage my season with my kz. i'm hoping that my throttle shaft seals fix my problemLast edited by Guest; 09-19-2014, 12:52 PM.

Comment

-

William Groebe

William Groebe

Look who's ready to ride to work tomorrow!

Thanks to everyone for the helpful hints. This was my first foray into the world of motorcycle maintenance. I started with a pretty hefty task, but took baby steps the whole way. She's running well with no visible leaks, and a working 2nd gear. There's a lot more needed to make her pretty, but for now she runs.

Life is good.

Comment

-

I agree. William, you've done a great job. If your first foray into motorcycle maintenance includes successfully rebuilding your engine easily enough then you're a natural. I like your path of clean but not too shiny. Glad it all worked out. The pictures and descriptions were great and will certainly help others down the road. Tell us how the ride to work was.Originally posted by barnbiketom View Postlookin good! after re-looking at you pics, I think my 650L's whine may be normal.. there's a few things in there that might be the source but I've just accepted the noise for now, and it's for sale anyway hahah. Good work.. you can work on my engine Anytime!!Erik

1982 GS550M

Dyna S, Dyna greens, coil relay mod w/LED, Sonic Springs (.90)

Comment

-

barnbiketom

barnbiketom

+1 on motorcycle "maintenance??" hahahaha, like I said, you can work on my bike any time..hope she goes well for you!!Originally posted by Missile99 View PostI agree. William, you've done a great job. If your first foray into motorcycle maintenance includes successfully rebuilding your engine easily enough then you're a natural. I like your path of clean but not too shiny. Glad it all worked out. The pictures and descriptions were great and will certainly help others down the road. Tell us how the ride to work was.

Comment

.png)

Comment