Announcement

Collapse

No announcement yet.

Billet clutch baskets are, well..... Fake?

Collapse

X

-

Forum LongTimerGSResource Superstar

Past Site Supporter

Super Site Supporter- Mar 2006

- 35712

- Torrance, CA

Blocks of billet are not forged. I'm repeating myself but they are cast or extruded and then (possibly) roll formed. These blocks then can be machined into a useful part. The finished part grain structure will NOT possess the aligned grain of a forged part.Ed

To measure is to know.

Mikuni O-ring Kits For Sale...https://www.thegsresources.com/_foru...ts#post1703182

Top Newbie Mistakes thread...http://www.thegsresources.com/_forum...d.php?t=171846

Carb rebuild tutorial...https://gsarchive.bwringer.com/mtsac...d_Tutorial.pdf

KZ750E Rebuild Thread...http://www.thegsresources.com/_forum...0-Resurrection

-

Looking at the pic posted, I'd say it's a pressure die casting. Given the surface finish which is way better than a sand casting I'd also pick that it's been properly done with a chilled former for the interior surfaces.

Given a choice between "as machined" billet basket from possibly a good quality 6000 series alloy and a good diecast one, I'd go for the diecasting.

Unless you're running a top fuel dragbike you're not going to need anything better than the good diecasting.

Comment

-

This is how I read it....Originally posted by JJ View PostWhich part did YOU not grasp

Advantages of billet:

- Cost effective in low quantities

- High degree of precision

- Very short lead times

- Structurally the parts are stronger

I form and heat treat aluminum parts all day. 6061 and 2024. 2024 is a stronger metal but not as corrosive resistant as 6061. We have a HAAS Mill and I could actually mow a basket out if I had the program.....

Last edited by bonanzadave; 09-04-2017, 11:14 AM.82 1100 EZ (red)

"You co-opting words of KV only thickens the scent of your BS. A thief and a putter-on of airs most foul. " JEEPRUSTY

Comment

-

I would guess he can not grasp how you can't even properly relate the reference your posted. Your article did not mention forging once.Originally posted by JJ View PostWhich part did YOU not grasp, Ed? I understood it just fine.

This is not to suggest that the article is necessarily authoritative, just you have read much more into it.

Comment

-

Forum LongTimerGSResource Superstar

Past Site Supporter

Super Site Supporter- Mar 2006

- 35712

- Torrance, CA

There are some nifty youtube videos showing engine blocks and heads being milled out of a huge block (billet) of aluminum. Very cool stuff. I suppose JJ is going to tell us that the block was "forged", even though it was about 3' square to begin with?

I'll take a forged part over a milled from billet part any day if strength and toughness is one of the critical needs. Aircraft landing gear parts are typically forged. The forging process aligns the material grain structure and typically adds toughness (ability to absorb impact forces without failing) as well as ductility (not brittle).

This discussion has gone off the farm now though. I agree with Greg T in his assessment that a quality cast clutch basket is more than strong enough for it's intended usage.Ed

To measure is to know.

Mikuni O-ring Kits For Sale...https://www.thegsresources.com/_foru...ts#post1703182

Top Newbie Mistakes thread...http://www.thegsresources.com/_forum...d.php?t=171846

Carb rebuild tutorial...https://gsarchive.bwringer.com/mtsac...d_Tutorial.pdf

KZ750E Rebuild Thread...http://www.thegsresources.com/_forum...0-Resurrection

Comment

-

Forum LongTimerBard Award Winner

GSResource Superstar

Past Site Supporter

Super Site Supporter- Oct 2003

- 17459

- Indianapolis

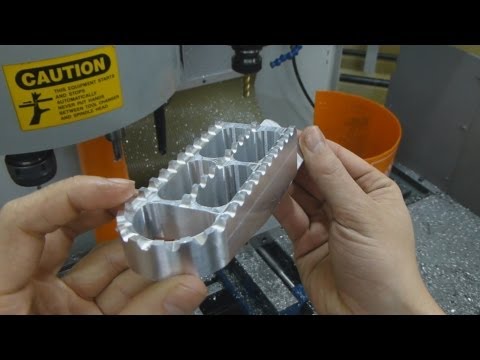

We have one small photo of the part, but I'll just point out that the object in the photo could very well have been machined from <<whatever the hell you lot of nitpickers want to call a chunk of aluminum>> then bead blasted. Or it could have been forged or cast then blasted. And blasting can have some strength benefits as well, or allow the part to better retain an oil coating, allow the clutch plates to move a little easier, etc. No way to tell for sure from one small low-quality photo. Frankly, it would be hard to tell for sure how it was made with it sitting on front of you.

The main beef seemed to be that tool marks weren't visible. Well, bear in mind that tool marks are actually defects, but over time people have come to associate the regular tool marks from automated machining with costly custom parts.

That Hays basket has heavy tool marks, which some people like the look of, but if they're deep enough they could cause a problem because the plates might not be able to move smoothly, same as a worn and notched stock basket. I'd much rather have the smooth finish on the Falicon basket.

I'm also trying to figure out why the Hays basket is anodized black -- or is that some sort of hard coating?Last edited by bwringer; 09-04-2017, 12:03 PM.1983 GS850G, Cosmos Blue.

2005 KLR685, Aztec Pink - Turd II.3, the ReReReTurdening

2015 Yamaha FJ-09, Magma Red Power Corrupts...

Eat more venison.

Please provide details. The GSR Hive Mind is nearly omniscient, but not yet clairvoyant.

Celeriter equita, converteque saepe.

SUPPORT THIS SITE! DONATE TODAY!

Co-host of "The Riding Obsession" sport-touring motorcycling podcast at tro.bike!

Comment

-

I need more popcorn and beer....Current Rides: 82 GS1100E, 00 Triumph 955 Speed Triple:twistedevil:, 03 Kawasaki ZRX1200, 01 Honda GL1800, '15 Kawasaki 1000 Versys

Past Rides: 72 Honda SL-125, Kawasaki KE-175, 77 GS750 with total yosh stage 1 kit, 79 GS1000s, 80 GS1000S, 82 GS750e,82 GS1000S, 84 VF500f, 86 FZR600, 95 Triumph Sprint 900,96 Triumph Sprint, 97 Triumph Sprint, 01 Kawasaki ZRX1200, 07 Triumph Tiger 1050, 01 Yam YFZ250F

Work in progress: 78 GS1000, unknown year GS1100ES

Comment

-

sharpy

sharpy

Comment

-

Since no parting or casting lines are visible, my guess is the Falicon basket is forged and the blasted finish also leads me to believe it's been shot peened. Forging and shot peening (in most cases) usually mean a very durable part.

Clutch baskets aren't exactly precision/close tolerance pieces, a closed die forging can produce a part that needs very little finish machining.

Don't know much about Hays clutches, but MTC hard anodizes their slider baskets. Would assume Hays does the same thing.Thieves.....kill them all.

Comment

-

Forum LongTimerGSResource Superstar

Past Site Supporter- Oct 2006

- 13999

- London, UK to Redondo Beach, California

The bead blasting could have been done to take away the surface stresses in the material... (I.e. microscopic hard edges) which would also improve the parts strength

It's definitely been blasted at some point. That's not a machine finish of any type.

1980 GS1000G - Sold

1980 GS1000G - Sold

1978 GS1000E - Finished!

1980 GS550E - Fixed & given to a friend

1983 GS750ES Special - Sold

2009 KLR 650 - Sold - gone to TX!

1982 GS1100G - Rebuilt and finished. - Sold

2009 TE610 - Dual Sporting around dreaming of Dakar..... - FOR SALE!

www.parasiticsanalytics.com

TWINPOT BRAKE UPGRADE LINKY: http://www.thegsresources.com/_forum...e-on-78-Skunk/

Comment

-

80GS850GBob

80GS850GBob

In my 25yrs of making rivets, the wire is rolled round to it's shape and inherits a long straight grain {to an extent}...but all bets are off when one reforms it via the various blows it takes to get to the finished product. Stress relieving helps there.{heated up to relax the metal after it's been formed}

I agree about the billet slang...but you'll never hear of a handmade wooden table made from a billet of hardwood - lol - that term is generally reserved for the metal type crowds....as in "this piece was made from a chuck of billet" {whatever type it might've been}.

One of the truly neat things I've seen is powder casting....a dry powdered metal mixture is poured into a mold and pressed at high pressure {multi-ton}...if defective for some reason it can be ground back to powder. Then, if everything is ok on said part, it's ran thru heat treating to make for razor sharp edges as well as hard as heck. {Burgess Norton} I worked in a different plant across town though, but visited that one once and got to see it 1st hand. I worked in extrusion - 500/1000 ton vertical presses and a short hop on the 6 die National 750C former {wrist pins and tappets}.

Comment

.png)

Comment