Announcement

Collapse

No announcement yet.

Finally took the plunge.

Collapse

X

-

Forum LongTimerGSResource Superstar

Past Site Supporter

Super Site Supporter- Mar 2006

- 35900

- Torrance, CA

Very nice. Keep going.Ed

To measure is to know.

Mikuni O-ring Kits For Sale...https://www.thegsresources.com/_foru...ts#post1703182

Top Newbie Mistakes thread...http://www.thegsresources.com/_forum...d.php?t=171846

Carb rebuild tutorial...https://gsarchive.bwringer.com/mtsac...d_Tutorial.pdf

KZ750E Rebuild Thread...http://www.thegsresources.com/_forum...0-Resurrection

-

Flaggo60

Flaggo60

I hope you're going to continue progress reports with pictures! I'm planning the same project in the near future and would love to see the process.

Comment

-

J_C

J_C

Yeah man, a new powdercoat makes day and night difference, if your old one has some wear & tear. Mine definitely needed it; I'm so glad I stripped it down to do it.

Comment

-

Matchless

Matchless

Thanks! I will try to post some pictures as it progresses.Originally posted by Nessism View PostVery nice. Keep going.

Can anyone advise me on the next step. I want to powdercoat the wheels and my powdercoater says he cannot mask the metal rim and outsides of the spokes and can only do the complete wheel. I think it means he usually sandblasts the complete wheel and then powdercoats it. I would like to keep it stock. Does anyone have any advice on how to mask this off easily?

Comment

-

Matchless

Matchless

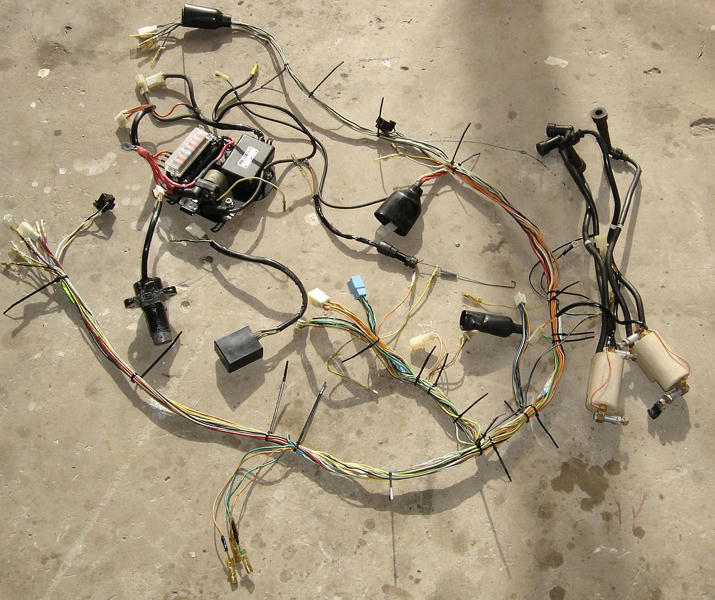

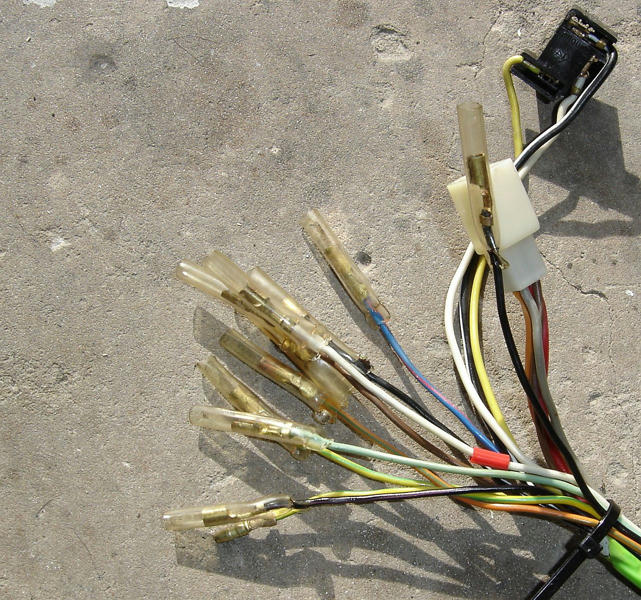

Pulled the tape off the wiring loom, removed the two redundant wires for the third phase charging and cleaned each wire full length with benzine.

Sprayed out all connectors and bullet connector boots with brake cleaner. Then dipped contacts in hydrofluoric acid for 5 minutes to clean the brass, dipped in clean water, sprayed with brake cleaner and finally sprayed with contact cleaner, left overnight and again cleaned each connector and conector block with brake cleaner. All connectors are now bright brass and the bullet connector boots look close to new.

Next step is to add new wires for coil and horn relay mod as well as a 12v accessory point and then wrap the loom up.

As the most problems on these old bikes are usually electrical or fuel related I am trying to do this properly.

Last edited by Guest; 06-29-2008, 12:14 PM.

Comment

-

seuadr

seuadr

wow man, you are making me feel tired just reading about it! awesome job! i really should do something like this over the winter. i already plan on hand polishing all my covers and stripping/cleaning and repainting all my brake parts.

Comment

-

These guys operate that service in the UK, and polish the outsides as well. Might be worth giving them a call and asking for a quote. If it's too dear with the shipping they might tell you how it's done.Originally posted by Matchless View PostThanks! I will try to post some pictures as it progresses.

Can anyone advise me on the next step. I want to powdercoat the wheels and my powdercoater says he cannot mask the metal rim and outsides of the spokes and can only do the complete wheel. I think it means he usually sandblasts the complete wheel and then powdercoats it. I would like to keep it stock. Does anyone have any advice on how to mask this off easily?

79 GS1000S

79 GS1000S (another one)

80 GSX750

80 GS550

80 CB650 cafe racer

75 PC50 - the one with OHV and pedals...

75 TS100 - being ridden (suicidally) by my father

Comment

-

Matchless

Matchless

I painted the calipers with high gloss black, 2 part (2k), a few months ago, messed some brakefluid on it during this tear down and the paint is lifting. I am definitely going to rather spend time on masking it off and having it powdered coated as well, just so much more durable.Originally posted by seuadr View Posti already plan on hand polishing all my covers and stripping/cleaning and repainting all my brake parts.

If you want to polish your covers, get a bench grinder and fit a mulilayer cotton wheel and get some paste. You have to remove the covers, but the end result is so easy and good that it is really worth it.

Comment

-

Matchless

Matchless

Thanks, but the shipping cost may cripple the rest of the project! I am hoping for a method that I can apply in conjunction with my local powdercoater as they do not really do those specialised type of jobs. If I can prepare it properly for sandblasting and powdercoating they will do it, but..Originally posted by hampshirehog View PostThese guys operate that service in the UK, and polish the outsides as well. Might be worth giving them a call and asking for a quote. If it's too dear with the shipping they might tell you how it's done.

http://www.triple-s.co.uk/

Comment

-

Forum LongTimerGSResource Superstar

Past Site Supporter

Super Site Supporter- Mar 2006

- 35900

- Torrance, CA

More excellent work on the harness. I love to see a job that is being done the RIGHT way.:-)

Since your wheels are for a G (shaft drive), you can easily get away with a liquid paint on the wheels since no chain lube will be used. I like PPG two part urethane paint; holds up very well to paint chips and chemicals. If you have the rims sandblasted, after proper masking, the finish will hold up just fine if you use some proper paint (not rattle cans).

As a side note, I've heard of a special type of tape for powercoating but don't have any personal experience. The edge of the rims could be covered I think but the ribs on the spokes would be difficult for sure.

Good luck.Ed

To measure is to know.

Mikuni O-ring Kits For Sale...https://www.thegsresources.com/_foru...ts#post1703182

Top Newbie Mistakes thread...http://www.thegsresources.com/_forum...d.php?t=171846

Carb rebuild tutorial...https://gsarchive.bwringer.com/mtsac...d_Tutorial.pdf

KZ750E Rebuild Thread...http://www.thegsresources.com/_forum...0-Resurrection

Comment

-

Matchless

Matchless

Thanks for that suggestion. I have also been toying with the idea to have the rims sandblasted and powdercoated in silver and then just painting the inner parts of the rims over the powdercoating a charcoal color. I will obviously lose the bare polished metal affect and was wondering if this would not 'look' wrong.

Comment

-

Forum LongTimerGSResource Superstar

Past Site Supporter

Super Site Supporter- Mar 2006

- 35900

- Torrance, CA

Powder coat is not magic so don't be afraid of liquid paint - just use the right stuff.

FYI, you might want to check BassCliff's instructions on how to post photos. Very informative. http://members.dslextreme.com/users/...t_pictures.pdfEd

To measure is to know.

Mikuni O-ring Kits For Sale...https://www.thegsresources.com/_foru...ts#post1703182

Top Newbie Mistakes thread...http://www.thegsresources.com/_forum...d.php?t=171846

Carb rebuild tutorial...https://gsarchive.bwringer.com/mtsac...d_Tutorial.pdf

KZ750E Rebuild Thread...http://www.thegsresources.com/_forum...0-Resurrection

Comment

-

Matchless

Matchless

Thanks for the pointer. Unfortunately my pictures have a different process, but I managed to figure it out and reposted them. Hope it looks better now.

Comment

-

J_C

J_C

Dude... nice. I wish I had done that when my harness was off. Whats the benzine for, just to clean the insulation? And the hydroflouric acid got off any tarnish or corrosion from the wires and/or connectors?Originally posted by Matchless View PostPulled the tape off the wiring loom, removed the two redundant wires for the third phase charging and cleaned each wire full length with benzine.

Sprayed out all connectors and bullet connector boots with brake cleaner. Then dipped contacts in hydrofluoric acid for 5 minutes to clean the brass, dipped in clean water, sprayed with brake cleaner and finally sprayed with contact cleaner, left overnight and again cleaned each connector and conector block with brake cleaner. All connectors are now bright brass and the bullet connector boots look close to new.

Comment

.png)

Comment