I was planning to cut a new windshield and Larry D asked that I take some pics.

So…

Here they are with the story that goes with it. Sorry for the Typos and spelling. English is not my first language. I speak it well enough…Writing well…You be the judge.

I am not by far an expert and this is not meant to be a guide. But if others can comment it could be useful.

My 1100GK never had a new (Or original) windshield. I bought it with a PO made one. It is now crazed and developing cracks. It was made with some Plexiglas about 3mm thick. It did well but when I cut a new one with an extra 5cm it was fluttering at 120kph. Size or different material…not sure but it won’t do.

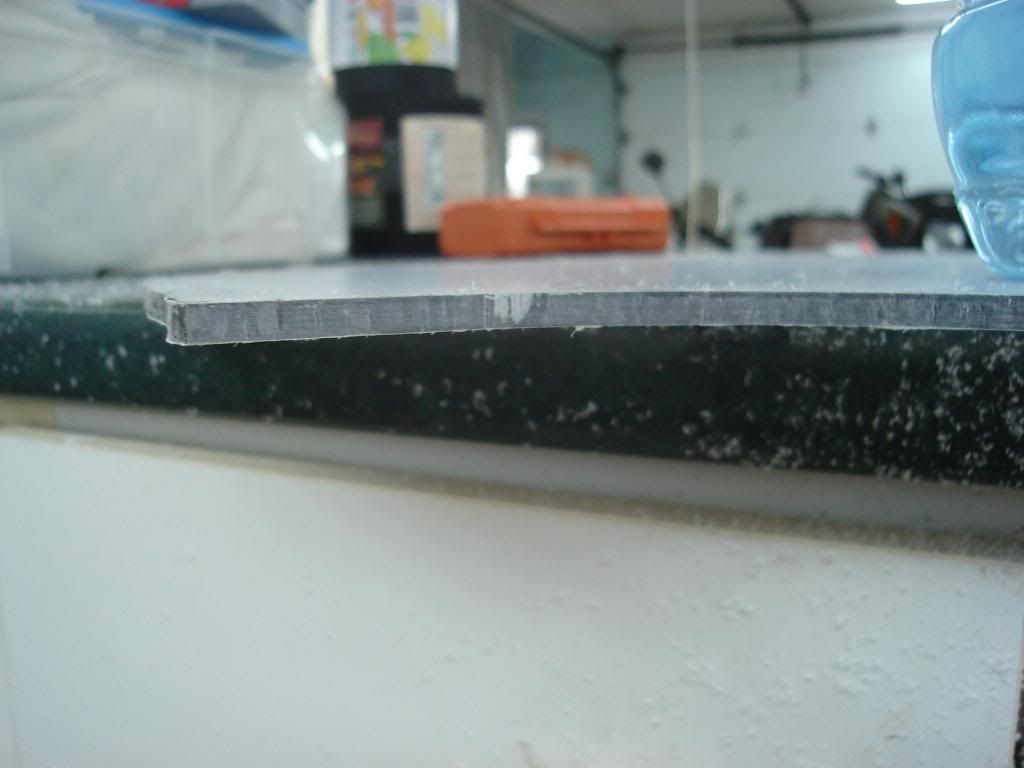

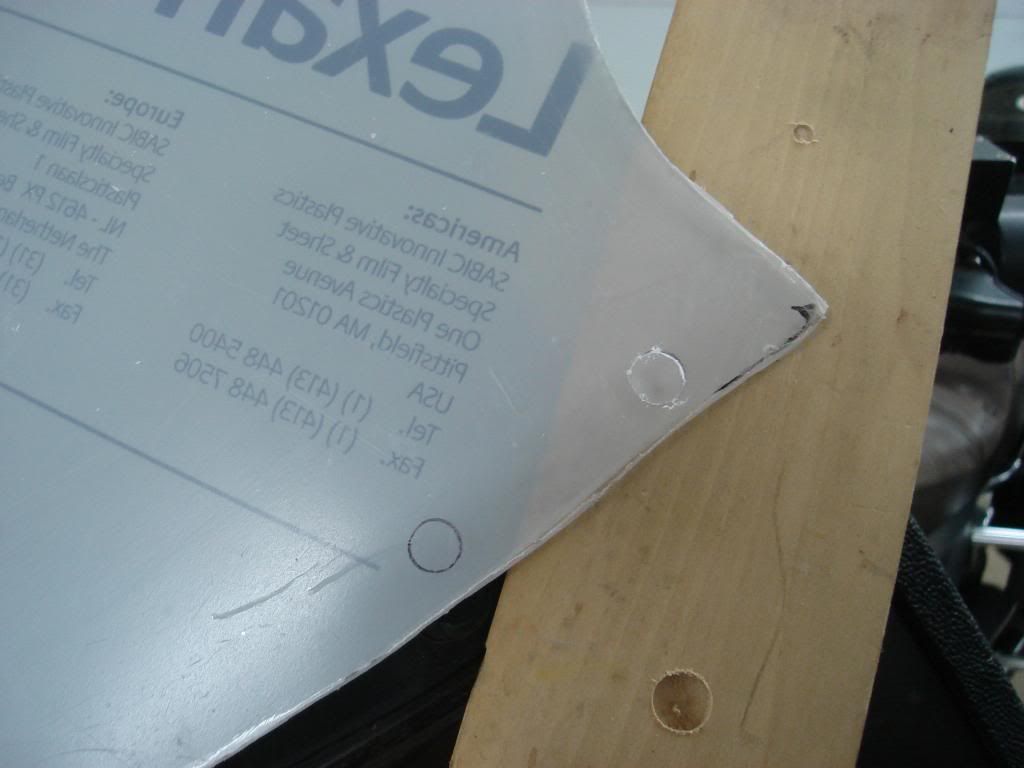

This newer windshield is cut from 4.5mm lexan.

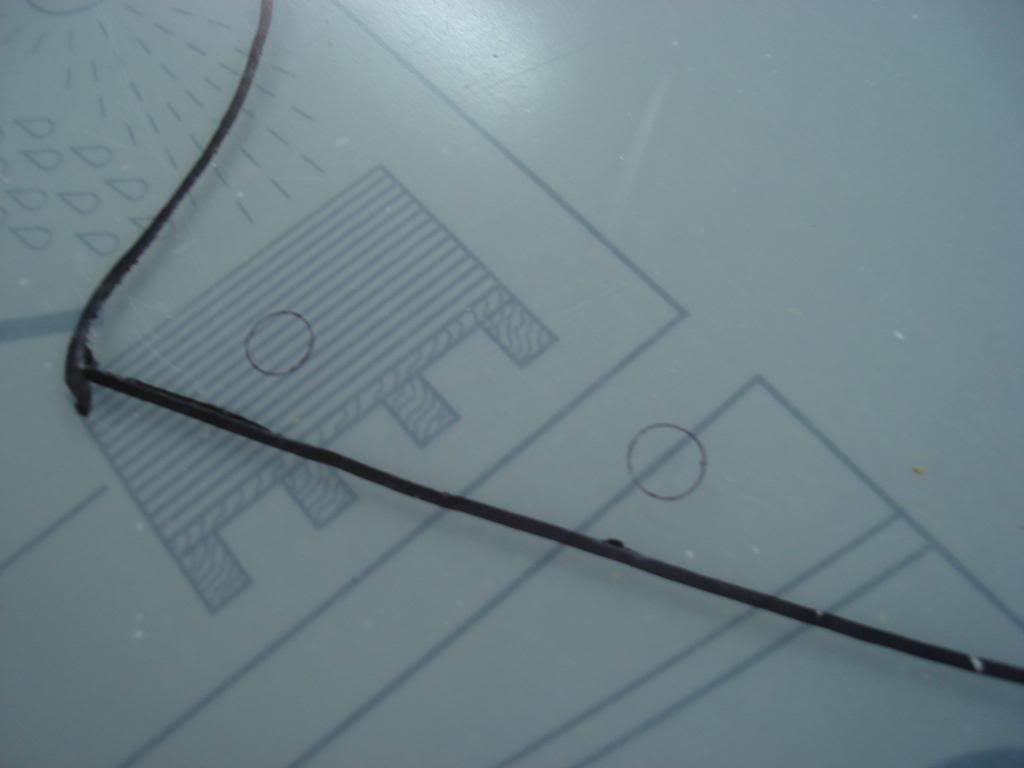

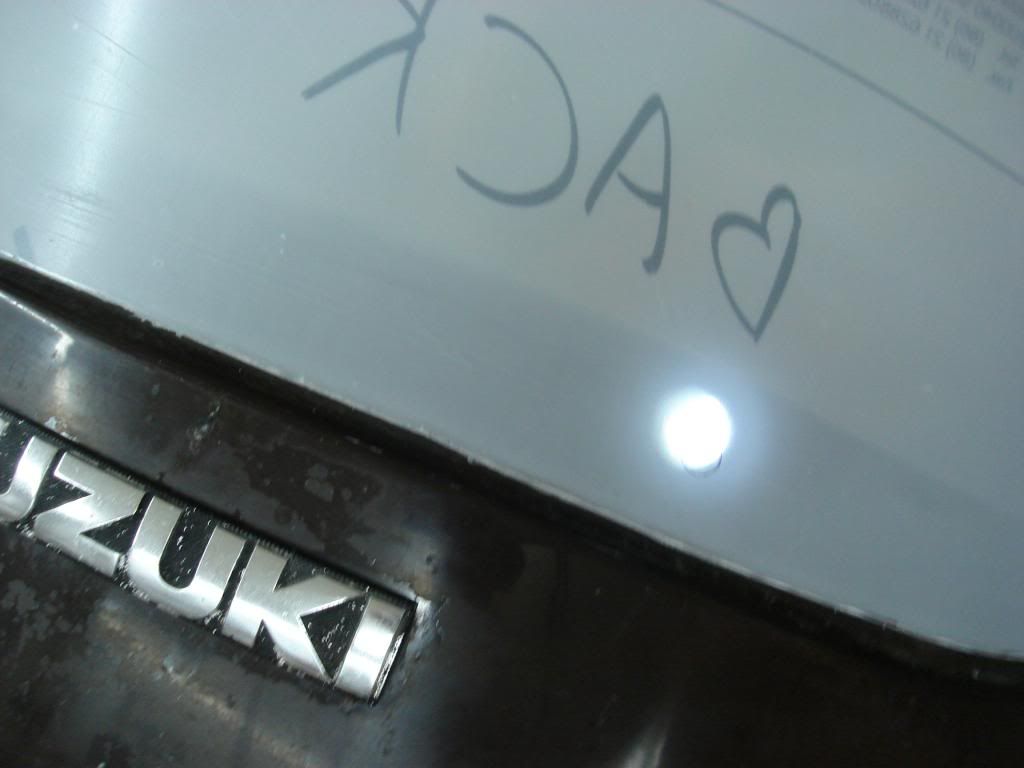

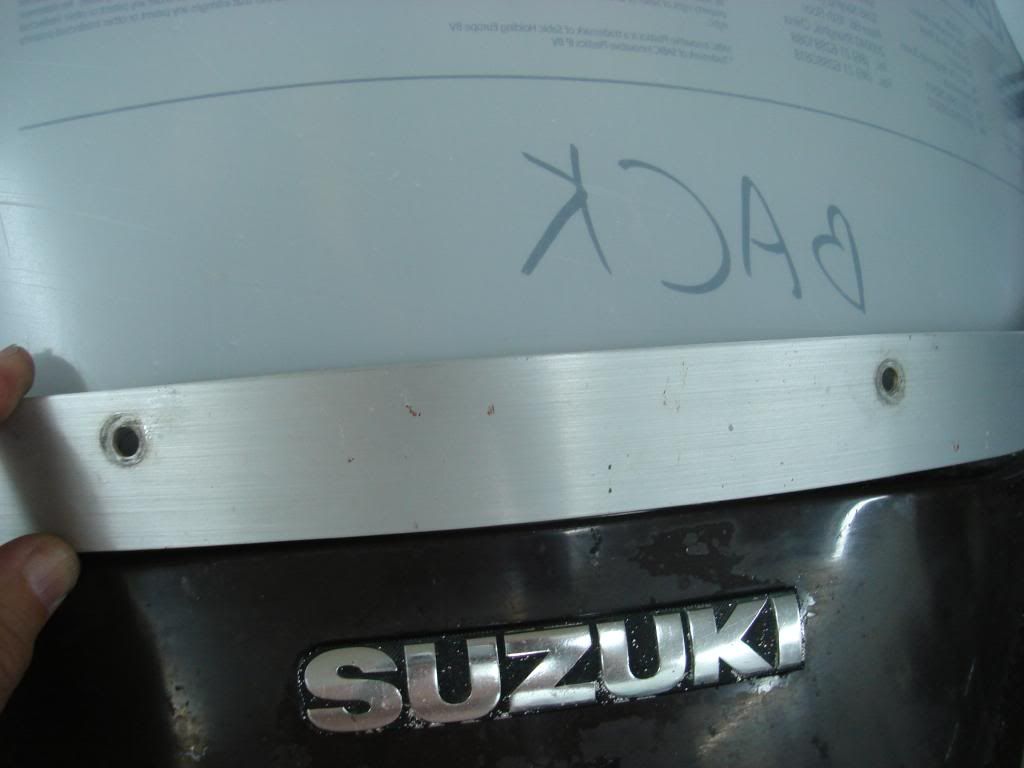

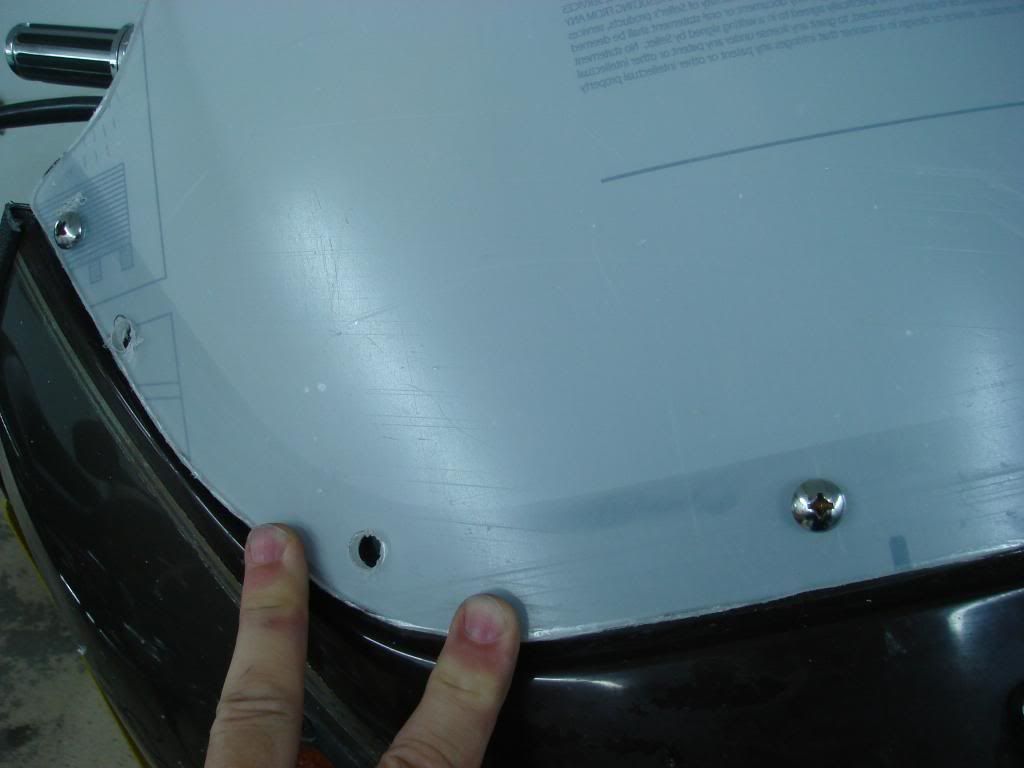

This is what the holes on my original windshield looks like.

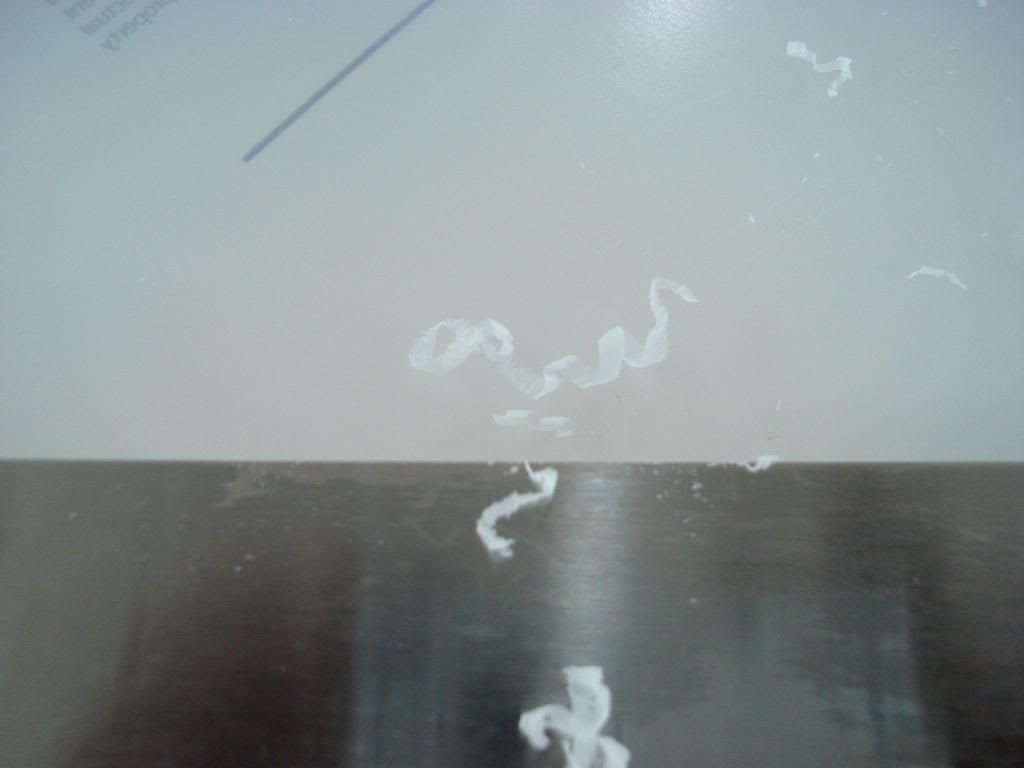

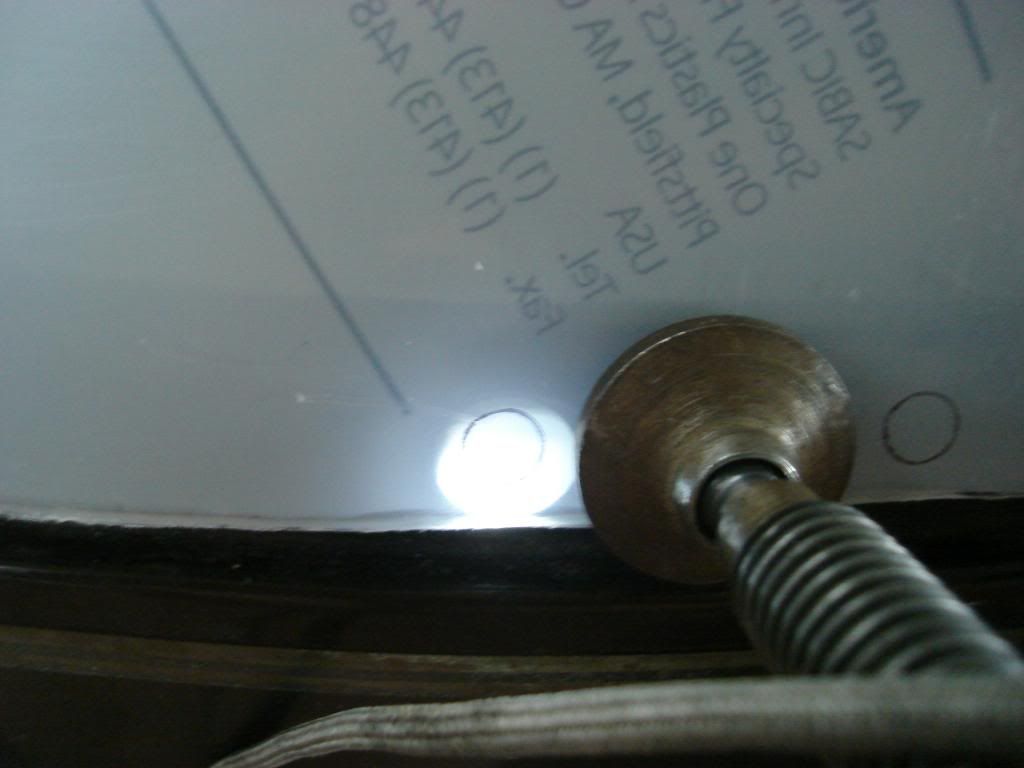

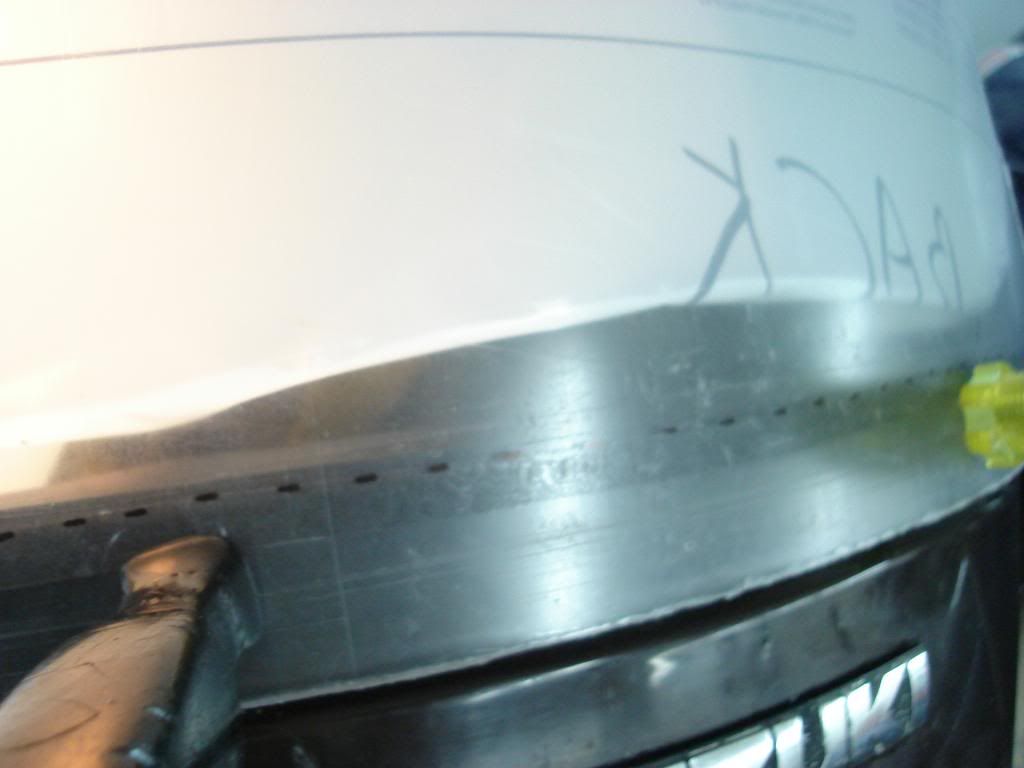

The inside of the windshield has this “Tape”. I think the original had a water barrier there. And the PO put some tape to emulate it. Unsuccessfully.

Comments?

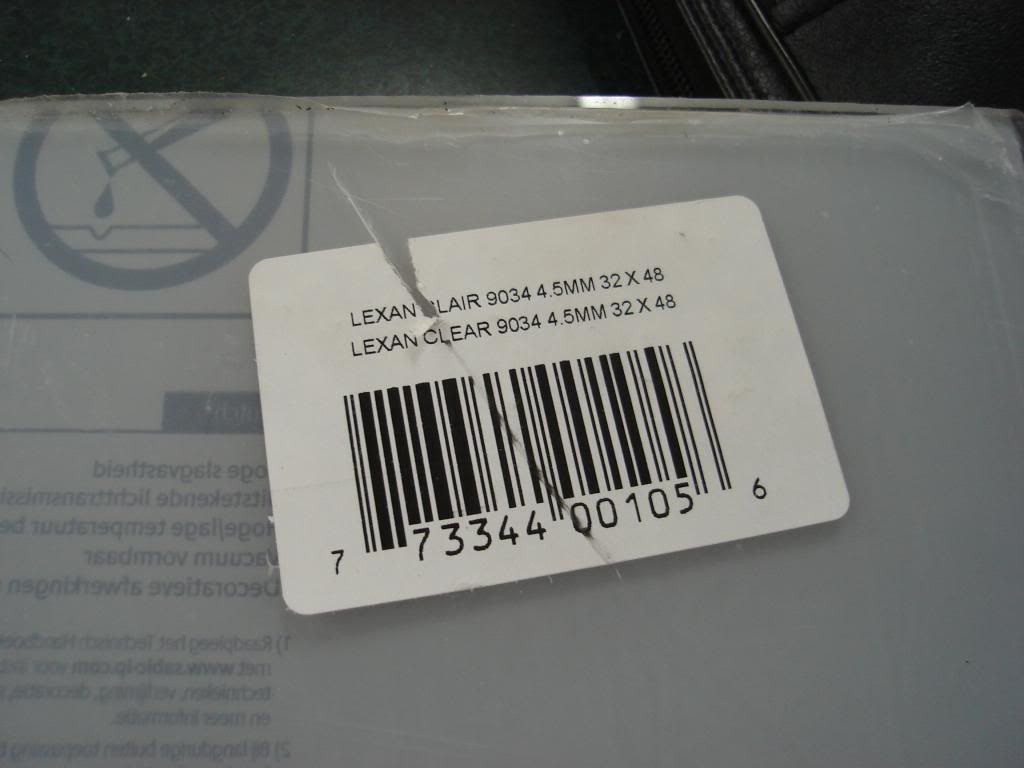

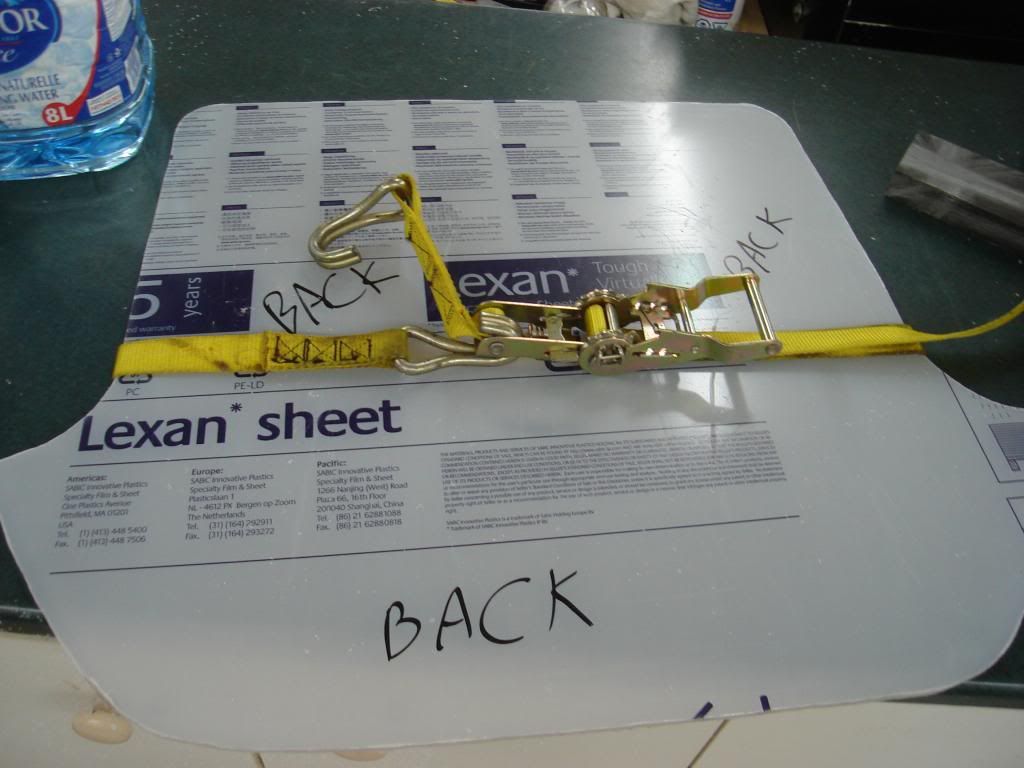

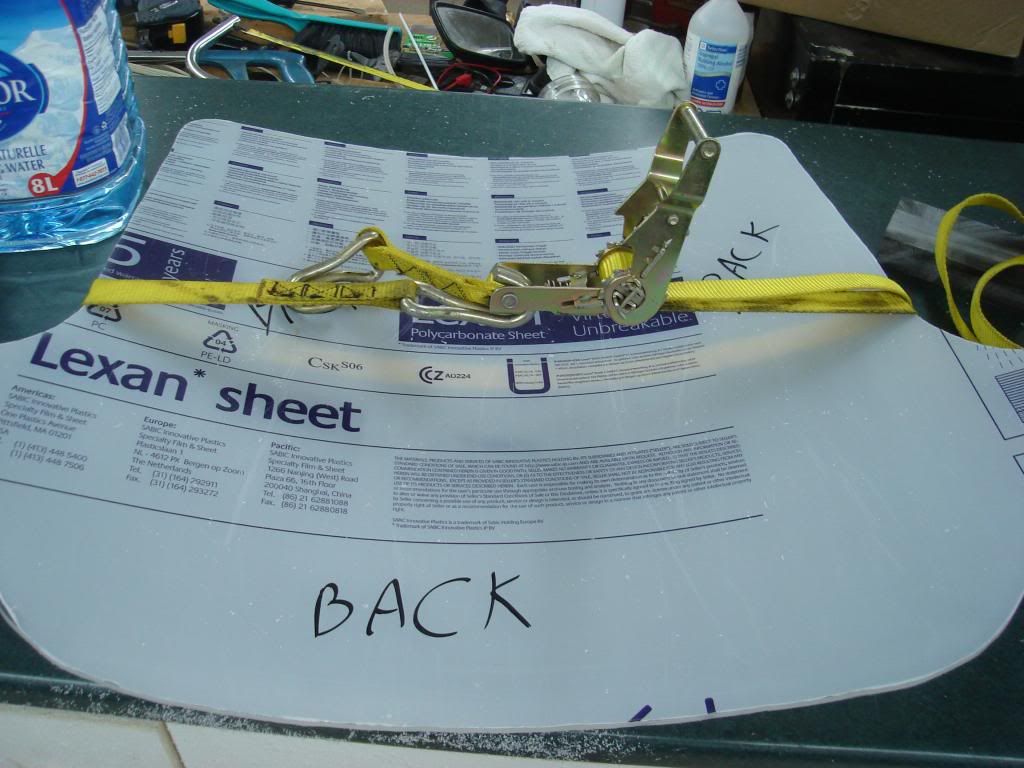

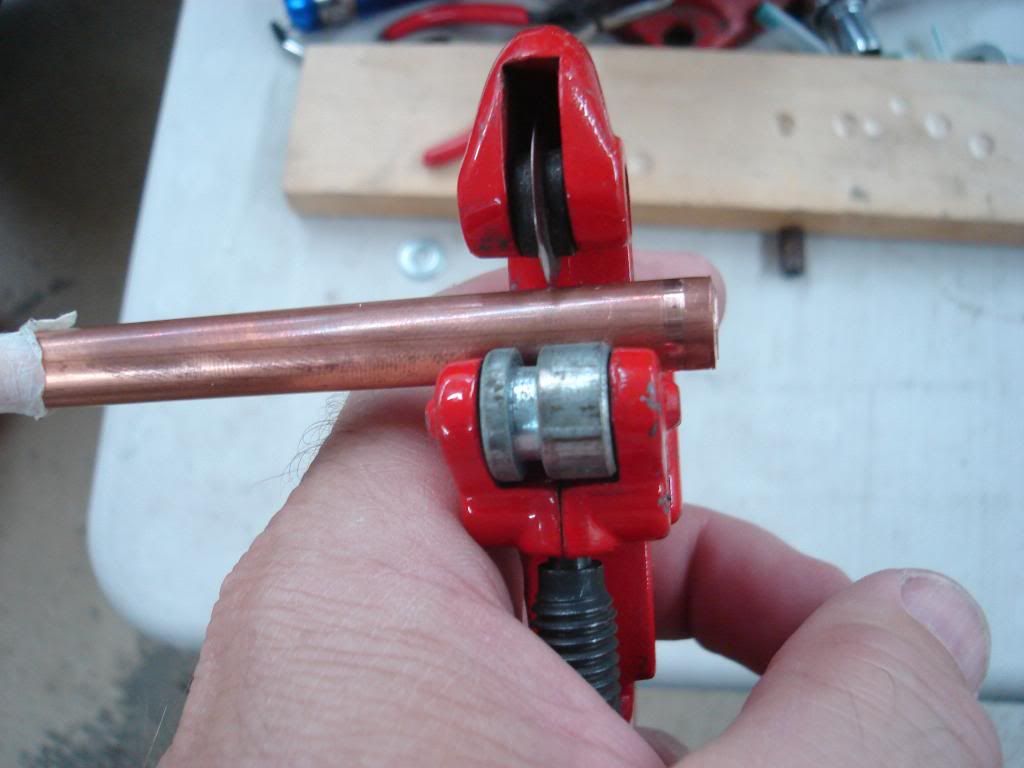

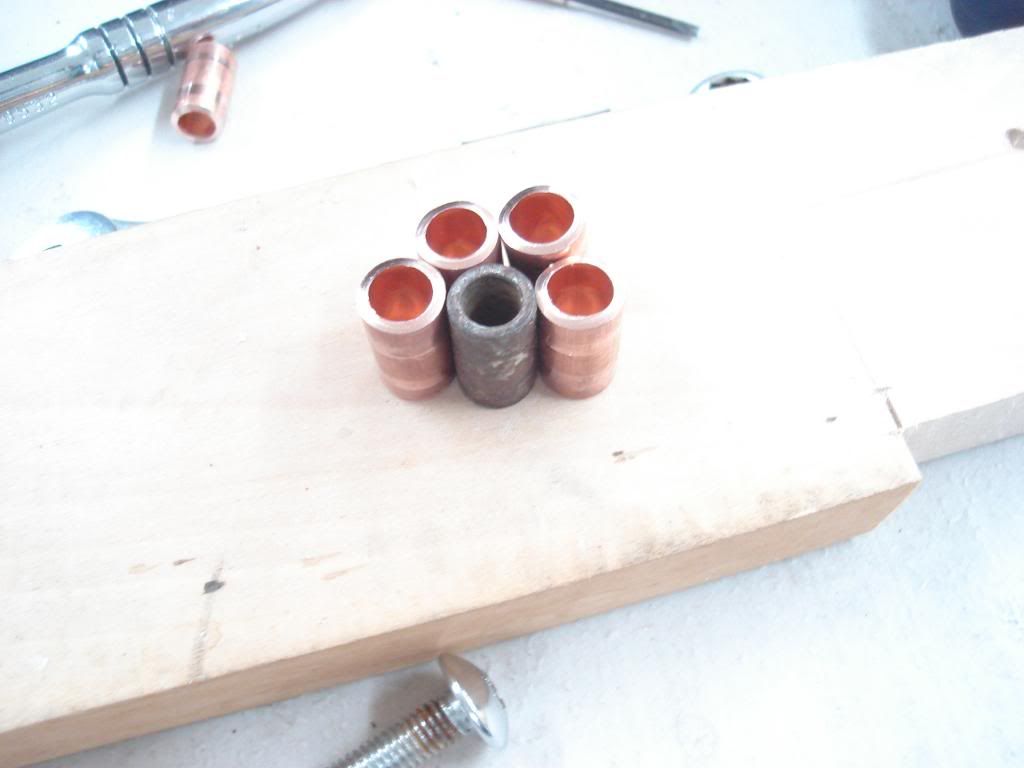

This is the stuff I purchased. Made 2 windshield with it. One for a Honda Helix one for the GK.

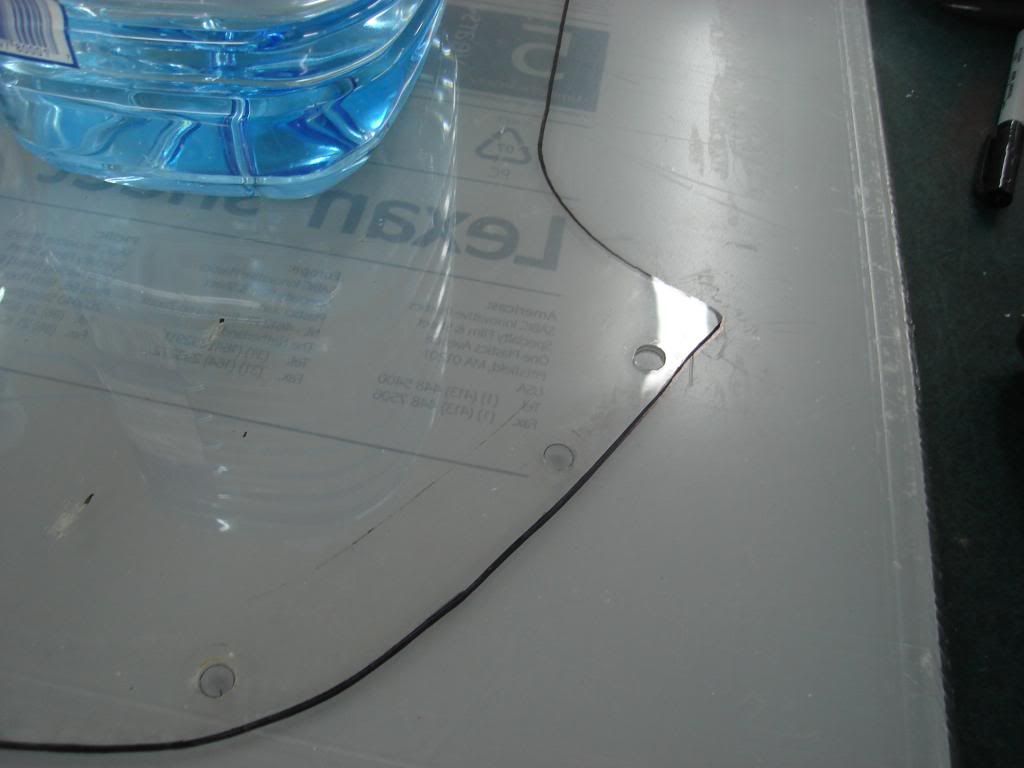

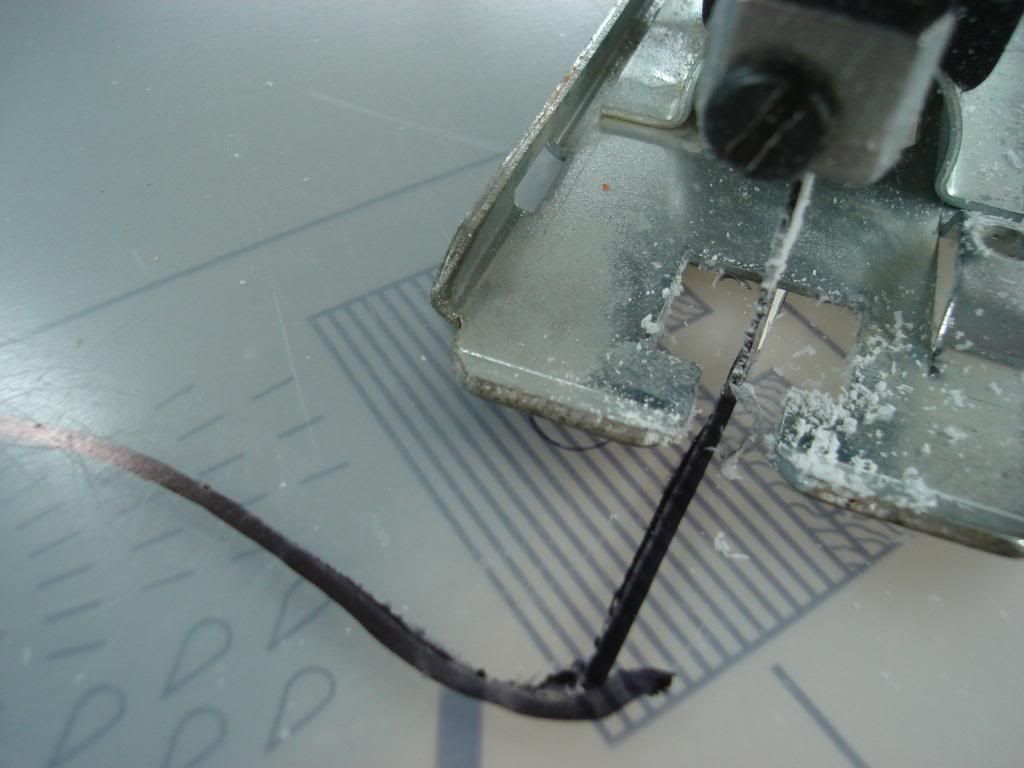

My working setup Lexan covered with my master and two jugs of water for weight.

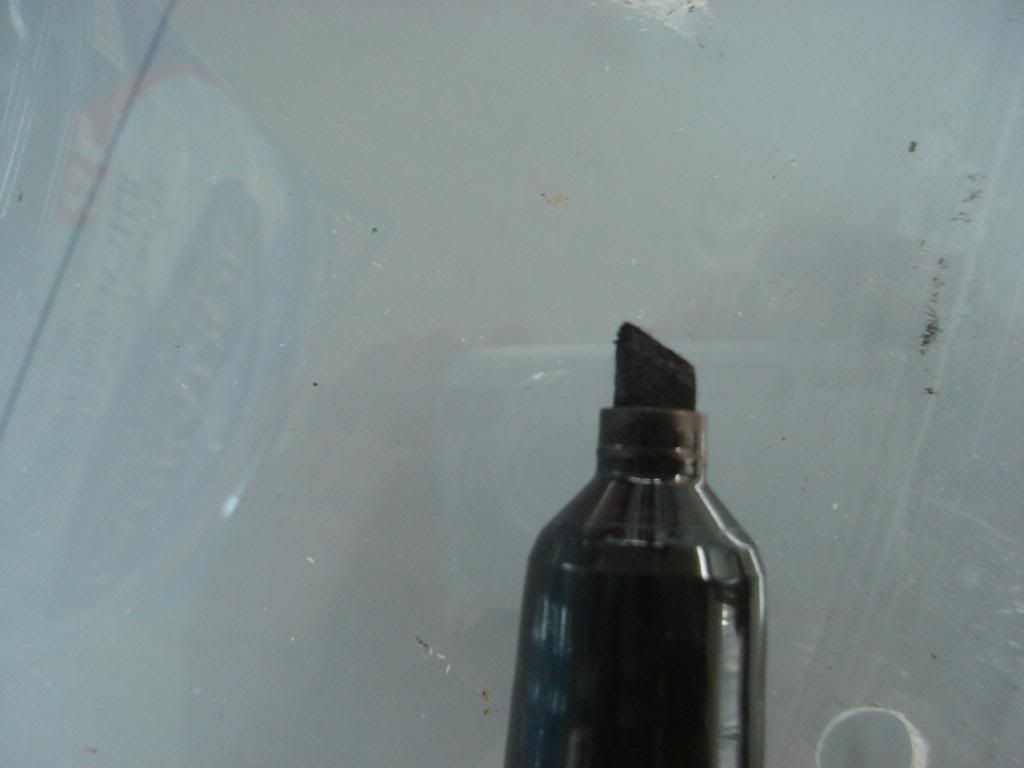

I used the pointy tip of a large permanent marker. I found that you should not “Press” the tip to your master as it squeezes the ink out and it wick under the master. It blurs the line.

Windshield marked

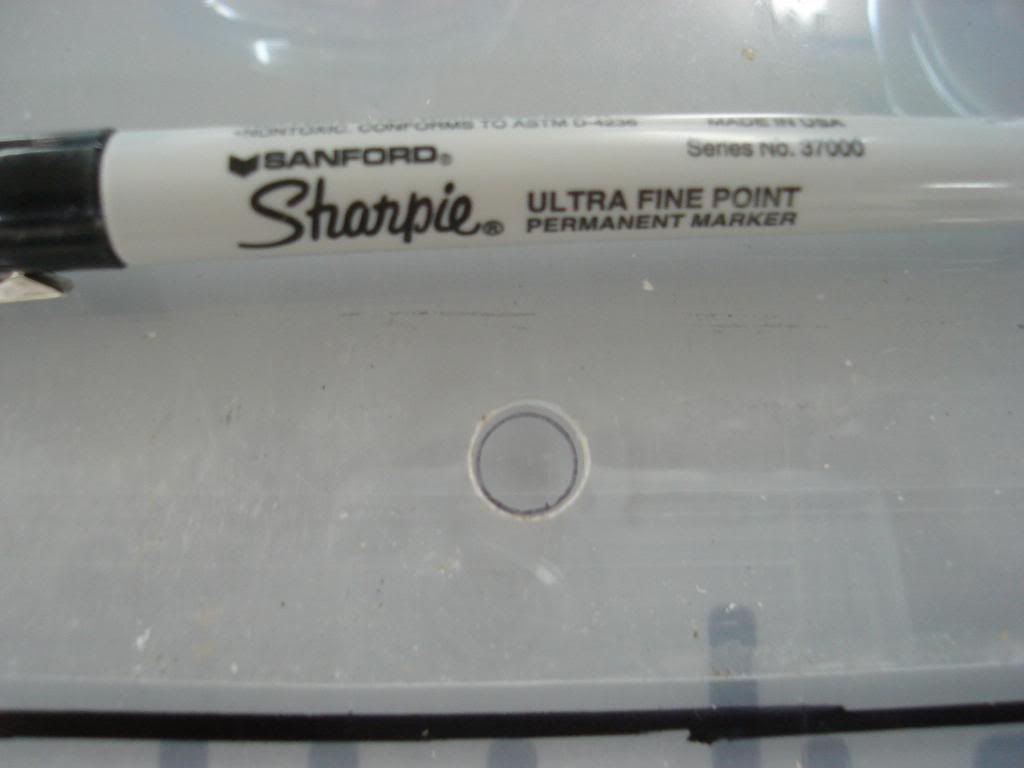

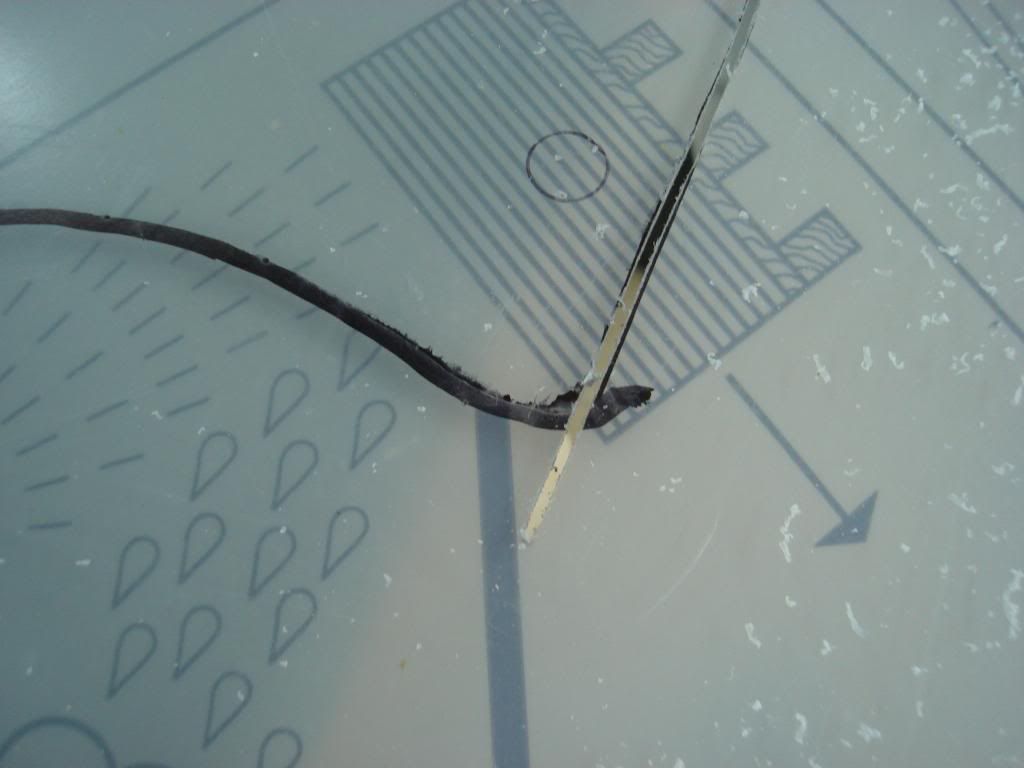

Holes marked with a fine point permanent marker. I would like to note that permanent or not, working with the sheet, the fine marker would start erasing. Not blur, erasing.

EDIT: In retrospect I should have filled in the hole. Made it a large dot.

More to come.

.png)

.

. . I will practice and try.

. I will practice and try. .

.

Comment