Announcement

Collapse

No announcement yet.

engine stand

Collapse

X

-

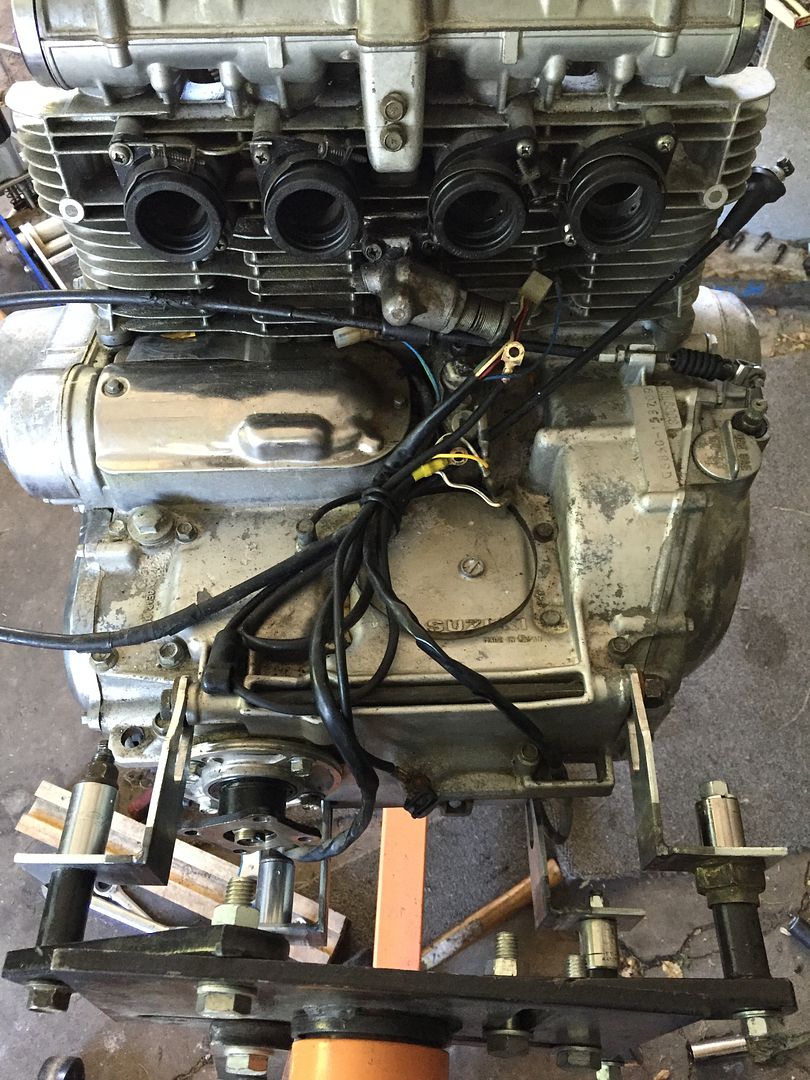

No reason not to. I used the rod so I could tighten everything up without the need for spacers.83 GS1100ES rebuild:

http://www.thegsresources.com/_forum...d.php?t=170032

Budget GSXR Conversion:

http://www.thegsresources.com/_forum...d.php?t=200563

New to me bike: 2008 B-KING

-

Didn't think so, just making sure you felt the same. I have a spare engine so even if there were concerns I could use those. Just need to slot/notch my brackets and make sure they fit before I have 2 more fabbed up and will post some pictures when I do.

For now, it hangs, ratchet strapped from the rafters:

----------------------------------------------------------------

----------------------------------------------------------------

2014 BMW F800GSA | 1981 GS850GX | 1982 GS750T (now the son-in-laws) | 1983 GS750ES | 1983 Honda V45 Magna (needs some love) | 1980 Yamaha GT80 and LB80 "Chappy" | 1973 and 1975 Honda XL250 projects

Comment

-

When doing full tear down don't you need another arm attached to the top part of the upper case? That way you can flip the upper case to empty and fill it with the crank and tranny.Originally posted by ShadowFocus603 View PostNic I think your setup is the most common method I have seen. Ill be using it when I do the full tear down on 750L #1.

Once the lower case has been removed thats when you would need the additional arm.

What everyone has posted so far would be fine for painting or external work on a complete engine, including R/R of jugs and head.

Nic, do you just split the cases on a bench once you have the head and jugs off?

Another way of doing it is using two cheap harbor freight stands mounted to a common base member. Gives you ability to rotate by attaching to front and rear upper motor mounts as well as split cases. You loose some front access. It's also a bigger thing to have around although this guy's bracket could be shorter. He says he had to weld things to make it but it looks like it could be done by just cutting pieces and bolting in a sleeve.

Comment

-

That works and gives you even more tip over margin. Not sure where I got the spare pipe from, but it wouldn't take much to overrun the cost of a new stand.Originally posted by isleoman View PostWhen doing full tear down don't you need another arm attached to the top part of the upper case? That way you can flip the upper case to empty and fill it with the crank and tranny.

Once the lower case has been removed thats when you would need the additional arm.

What everyone has posted so far would be fine for painting or external work on a complete engine, including R/R of jugs and head.

Nic, do you just split the cases on a bench once you have the head and jugs off?

Another way of doing it is using two cheap harbor freight stands mounted to a common base member. Gives you ability to rotate by attaching to front and rear upper motor mounts as well as split cases. You loose some front access. It's also a bigger thing to have around although this guy's bracket could be shorter. He says he had to weld things to make it but it looks like it could be done by just cutting pieces and bolting in a sleeve.

Comment

-

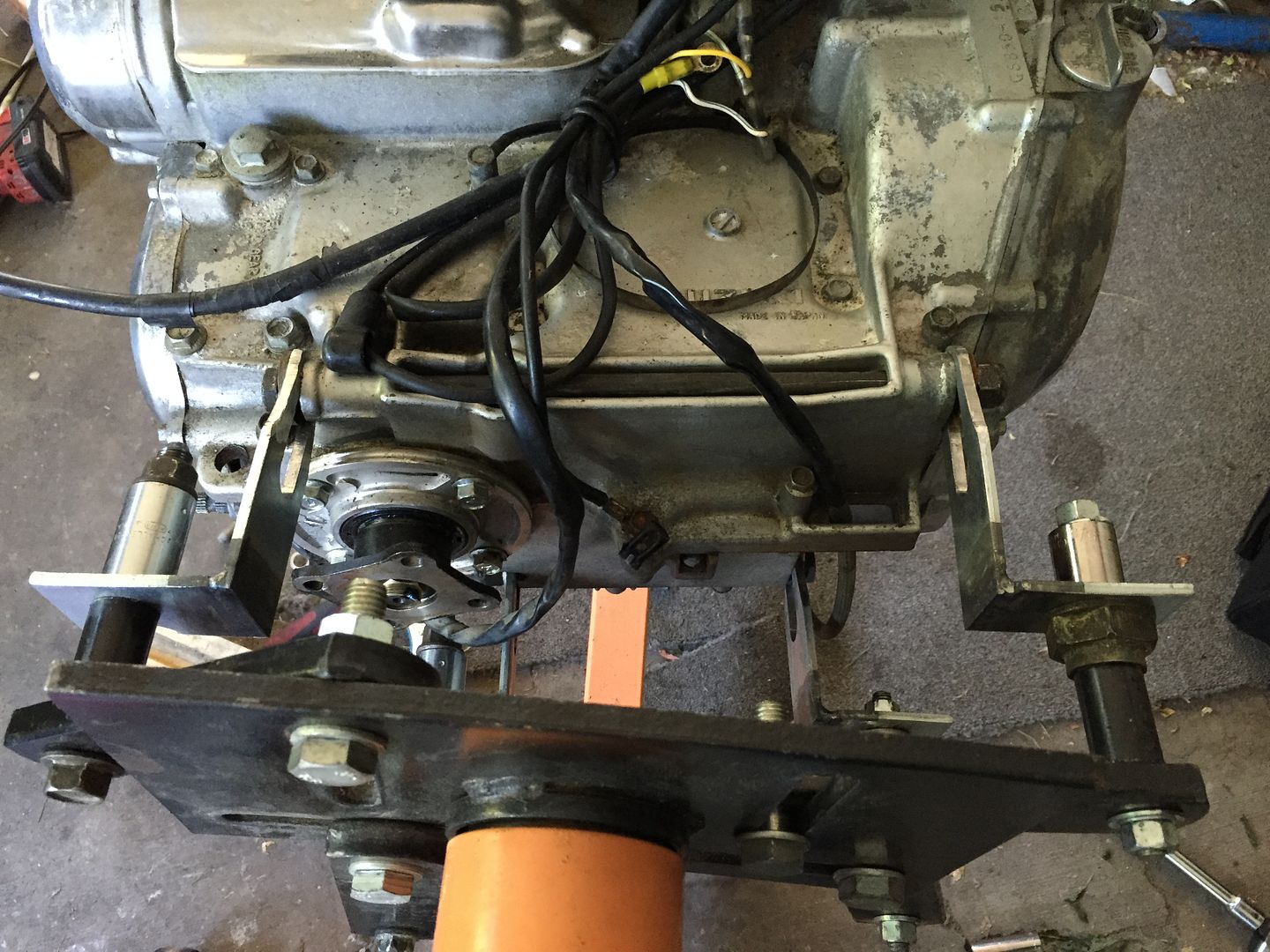

I cut my brackets in half and slotted them tonight, best tool I had handy for the Bridgeport was an 11/16" so the slot is a little big but I'll just use some big fender washers:

Also need to trim a little meat around the corners so it follows the contour of the transmission case better - stock mount shown over the top of my bracket:

----------------------------------------------------------------

----------------------------------------------------------------

2014 BMW F800GSA | 1981 GS850GX | 1982 GS750T (now the son-in-laws) | 1983 GS750ES | 1983 Honda V45 Magna (needs some love) | 1980 Yamaha GT80 and LB80 "Chappy" | 1973 and 1975 Honda XL250 projects

Comment

-

https://drive.google.com/open?id=0B9zH8w8Civs8ejBJWjdvYi1LNTg&resourcekey=0-hlJp0Yc4K_VN9g7Jyy4KQg&authuser=fussbucket_1%40msn.com&usp=drive_fs

1983 GS750ED-Horsetraded for the Ironhead

1981 HD XLH

Drew's 850 L Restoration

Drew's 83 750E Project

Comment

-

Nice!

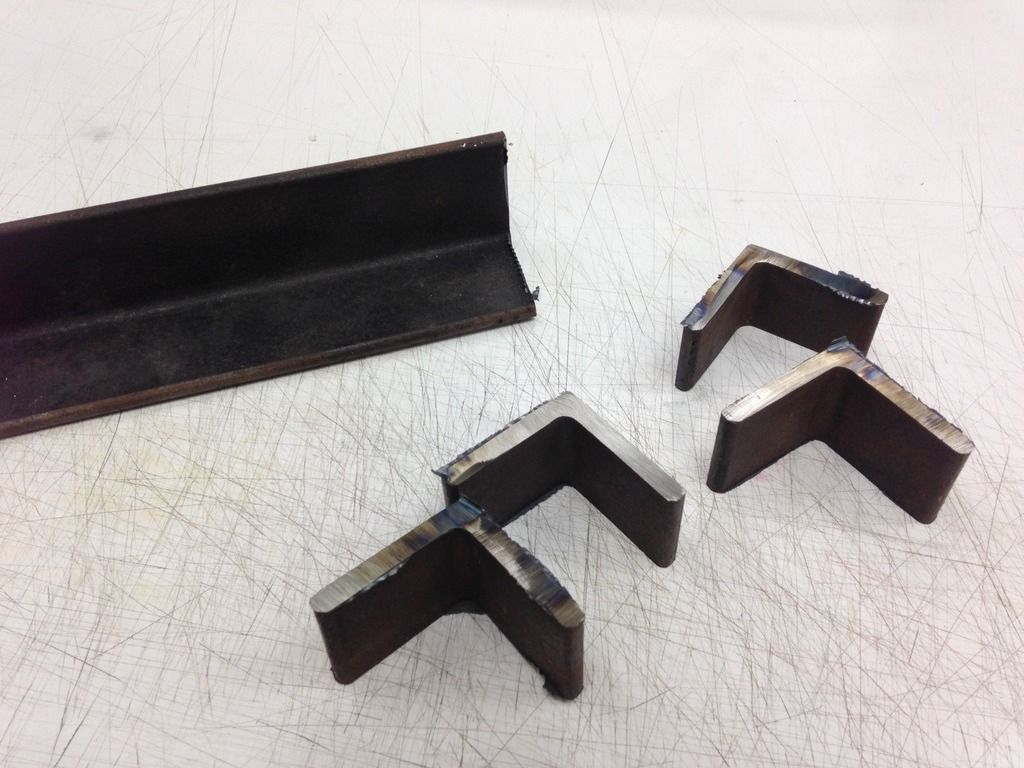

That looks perfect - simple and effective.I have the feeling that mine are going to a be a little long. I didn't have an angle on hand so I had to improvise.----------------------------------------------------------------

2014 BMW F800GSA | 1981 GS850GX | 1982 GS750T (now the son-in-laws) | 1983 GS750ES | 1983 Honda V45 Magna (needs some love) | 1980 Yamaha GT80 and LB80 "Chappy" | 1973 and 1975 Honda XL250 projects

Comment

-

Got my mounts finished, not pretty but will work just fine.

----------------------------------------------------------------

----------------------------------------------------------------

2014 BMW F800GSA | 1981 GS850GX | 1982 GS750T (now the son-in-laws) | 1983 GS750ES | 1983 Honda V45 Magna (needs some love) | 1980 Yamaha GT80 and LB80 "Chappy" | 1973 and 1975 Honda XL250 projects

Comment

.png)

Comment