Announcement

Collapse

No announcement yet.

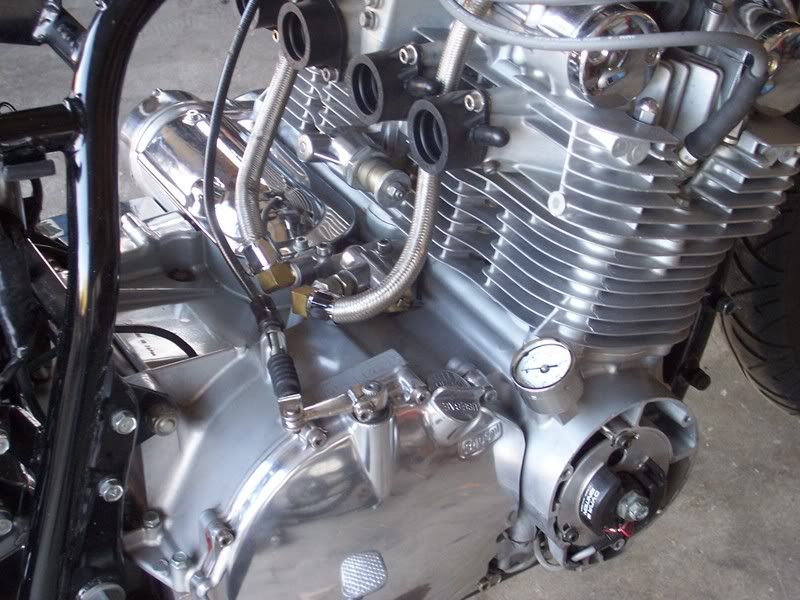

How to clean up the aluminum cases

Collapse

X

-

I have done just a very little bit of buffing. Two recommendations: eye protection and welding glovesOriginally posted by William Groebe View PostThis thread is timed perfect for me. I've got my engine in pieces and was researching what to do to clean it up before putting everything back together. wahoo!

Comment

-

80GS850GBob

80GS850GBob

Adding something behind the wheel{s} isn't a bad idea either....there's all sorts of "stuff" on the side of my toolbox at work from using the polishing wheel a little over a foot away from the back of it.Originally posted by Cipher View PostThe way you hold the pieces is very important. You can do yourself a serious mischief. A stout apron is also advised.

And yes, a good grip and angle of attack is very important when polishing....

Comment

-

80GS850GBob

80GS850GBob

Thanks, I'll check there for the color.Originally posted by Nessism View PostSears sells the black cutting compound. I didn't see a sisal wheel there though.

Did you start, usually, with a sisal wheel...then finish up with either a lighter sewn wheel or a loose unsewn wheel? {and lessor grit rouge of course}....curious.

Comment

-

So you have no problem with the cam chain tensioner or the oil pressure sensor?Originally posted by loud et View PostThat starter cover doesn't count Steve!

How about a breather cover?

Cam retainers?

Oil cooler manifolds?

Sorry, but if it's there, it deserves to shine.

.sigpic

mine: 2000 Honda GoldWing GL1500SE and 1980 GS850G'K' "Junior"

hers: 1982 GS850GL - "Angel" and 1969 Suzuki T250 Scrambler

#1 son: 1986 Yamaha Venture Royale 1300 and 1982 GS650GL "Rat Bagger"

#2 son: 1980 GS1000G

Family Portrait

Siblings and Spouses

Mom's first ride

Want a copy of my valve adjust spreadsheet for your 2-valve per cylinder engine? Send me an e-mail request (not a PM)

(Click on my username in the upper-left corner for e-mail info.)

Comment

-

loud et

loud et

I was just making a joke that the starter cover is already chrome. Of course all those other bits look great. I've seen your work before. Thumbs up.

Comment

-

And my point is that you should have a hard time telling the difference.

.sigpic

mine: 2000 Honda GoldWing GL1500SE and 1980 GS850G'K' "Junior"

hers: 1982 GS850GL - "Angel" and 1969 Suzuki T250 Scrambler

#1 son: 1986 Yamaha Venture Royale 1300 and 1982 GS650GL "Rat Bagger"

#2 son: 1980 GS1000G

Family Portrait

Siblings and Spouses

Mom's first ride

Want a copy of my valve adjust spreadsheet for your 2-valve per cylinder engine? Send me an e-mail request (not a PM)

(Click on my username in the upper-left corner for e-mail info.)

Comment

-

Forum LongTimerGSResource Superstar

Past Site Supporter

Super Site Supporter- Mar 2006

- 35640

- Torrance, CA

No, I don't use any other wheel. The sisal w/cutting compound brightens the aluminum more than enough for my tastes. It's actually brighter than that of the OEM Suzuki finish.Originally posted by 80GS850GBob View PostThanks, I'll check there for the color.

Did you start, usually, with a sisal wheel...then finish up with either a lighter sewn wheel or a loose unsewn wheel? {and lessor grit rouge of course}....curious.Ed

To measure is to know.

Mikuni O-ring Kits For Sale...https://www.thegsresources.com/_foru...ts#post1703182

Top Newbie Mistakes thread...http://www.thegsresources.com/_forum...d.php?t=171846

Carb rebuild tutorial...https://gsarchive.bwringer.com/mtsac...d_Tutorial.pdf

KZ750E Rebuild Thread...http://www.thegsresources.com/_forum...0-Resurrection

Comment

-

BurntKittyForge

BurntKittyForge

I had good luck on my GSX1100G using 500 grit wet/dry and then the brown "Tripoli" on a stitched wheel from harbor freight. Lastly I applied "Mother's Polish" and that really brings out a nicer shine or tone.

Without even using the finer grade polish stick/tubes I could see my own reflection in the pics of motor case.

Some sunny days I'd like to rub wax on and leave it for less sun glare. Looks great at night though.

My "Bit" for the buffer wheel is a long 3/8th inch bolt (All-thread would work same) , and a couple washers and nuts. Care is needed that the tip NEVER touches the metal. I use this bolt in a fairly powerful hand-drill and I really have to hold the drill firm. I notice my biceps really flexing and keep my left hand gripped to the drill body just behind the chuck. Really have to "man-handle" the drill to prevent slips, tip hitting ever/ injury. I DON'T wear gloves with that because they could possibly get caught in...

In past I made my own buffer portion for this bit out of carpet scraps cut close to round. That worked good on fork tubes.

The rotary tool (Dremel or similar) is essential for the small places. I avoided polishing anything I can't get to to apply some type of protectant and underneath sides (Unseen , unreachable Or subject to more road crud).

For some reason I've found the green scotch-brite pads too abrasive , leave more scratches, harder to get scratches out, so didn't use . Except for on the carb bowls ...

Hadn't started the rims yet but noticed cleaning vinegar takes the white corrosion right off. It flash rusts steel so been just doing small test sections of aluminum w/ care using that...(?)

Definately need safety glasses with the wire wheel (more w/ rotary tool) ...works great on the small bits, but low speed so the little needles don't shoot off ...

One time I tried a homemade denim wheel in an angle grinder , it just exploded apart and flapped ...amusing though.

Oh, I'm not polishing the hadlebar parts or top of triple trees , experience tells me it's a nuisance riding in sun with that stuff shiny.

Good Luck, and maybe post some pics ?

Comment

-

SVSooke

SVSooke

I have used walnut shells to good effect.Not great for getting any corrosion off but if there's a fine pattern on a piece you want to keep it's the way to go.Originally posted by Steve View PostI have tried glass bead, aluminum oxide and walnut shells, all at about 90psi. The walnut shells didn't do anything except waste some time (OK, a LOT of time), the other two looked pretty much like shibby's picture.

.

The GPz peg brackets have just such a pattern in them,to keep that it was great.Tried on the rest of the bits and quickly changed out media.It's nice to have when needed though.

Comment

.png)

Comment