Announcement

Collapse

No announcement yet.

Backfiring causes?

Collapse

X

-

almarconi

almarconi

I find it hard to believe that the bike was running fine and now there is no compression and it will not start. More than likely something is not assembled correctly. I would remove the valve cover and check your valve clearances and your cam timing. Check over everything you did.

-

Skateguy50

Skateguy50

Okay, keep it simple Ali and focus on what you did so far.

It ran before you got into this mini project, so start with what you did and what could cause the outcome. It sounds to me like the "zip tie" method has caused an issue with the valves seating, this is my big fear with it and why I fuss around with locking them on the top with a drill attachment on the cams... I should really buy the tool.

Anyways the zip tie isn't that hard and should not have been able to bend the valve or scratch it, that's the entire point of using them I guess. However as you said maybe it dislodged some carbon or even cleaned up some carbon but only in one part.

Now the question becomes can you right that wrong without 1) damaging the engine or 2) doing a top end rebuild. I am not so sure there is a good answer to that.

If it was me (I know its not) I would say if you think you are going to park it for a while anyways... find a good spot to park it and take a peak a bit deeper in the engine before you buy any gaskets or spend any money. If you can fix it up you will need a new base and head gasket to button it back up and the whole (while I am here mentality) can kick in and you might consider the rings and honing as well as the valve stem oil seals. Again start small to big and if you get the head off and remove and store the shims and buckets in order to not mix them up, then flip it over and see what the valves look like. If you are getting 0 compression it will be obvious if its the valves fault.

as a ball park on my 650 I am in about $300 for gaskets and 4 sets of rings, then another $45 for the shop to do the cylinder honing (you can order them up for like $35 online and do it yourself). oh and about 3 weeks of not riding and maybe 8 hours of actual wrenching.

Comment

-

No Way!

0 compression? You have to find out why. It don't go to 0 on it's own.Originally posted by Allie View PostRough compression test results, taken with the carbs on, plugs out, wide open throttle.

No oil:

#1 - 100 psi

#2 - 0 psi

#3 - 60 psi

#4 - 100 psi

Oil squirted in cylinders:

#1 - 150 psi

#2 - 0 psi

#3 - 100 psi

#4 - 230 psi !!!!!!!!!!

It seems fairly obvious that I need a rebuild before it ever sees the road again, and that's just not going to happen right now. I guess it's going into storage and I'll think about it again in the spring

Bummer, remember it was running. A little sleep and in a week or so an idea will come to you about how and why. Kind of like figuring out a melody in your sleep.

I think the cam chain is off. Because one cylinder is way high and another is why low, are you dyslexic? Bummer to take it all apart again, but when you're curious you'll unbolt it. It don't cost nothin' to unbolt the top. Try to save the gaskets.

Bill1982 GS1100G- road bike

1990 GSX750F-(1127cc '92 GSXR engine)

1987 Honda CBR600F Hurricane

Comment

-

raistian77

raistian77

+1Originally posted by almarconi View PostI find it hard to believe that the bike was running fine and now there is no compression and it will not start. More than likely something is not assembled correctly. I would remove the valve cover and check your valve clearances and your cam timing. Check over everything you did.

you are missing something.

When I used to rebuild diesel and gas engines for a living I made a habit of tapping each valve spring after assembly. Valves are notorious for hanging slightly open. Using the zip tie method is great but has a bad habit of loosening up carbon and lodging valves open just enough to throw compression in the garbage.

Good luck

Comment

-

Well yeah, I'm trying to figure out why it went to 0, and the 230 has me worried too, that just doesn't seem right.Originally posted by Buffalo Bill View Post0 compression? You have to find out why. It don't go to 0 on it's own.

Bummer, remember it was running. A little sleep and in a week or so an idea will come to you about how and why. Kind of like figuring out a melody in your sleep.

I think the cam chain is off. Because one cylinder is way high and another is why low, are you dyslexic? Bummer to take it all apart again, but when you're curious you'll unbolt it. It don't cost nothin' to unbolt the top. Try to save the gaskets.

Bill

Okay forgetting all about the carbs for the moment, the ONLY thing I did under the valve cover was measure all the clearances (all but two were under .05mm, the smallest I can measure atm), and then using the zip tie method I removed one valve shim at a time, measured it and wrote it down, then put the shim back in its bucket. Then moved on to the next shim. All valve shims went back in their buckts and were seated flat. I did not botch this, period.

Nonetheless no one has more trouble believing this whole thing than me, and obviously I AM missing something. Something happened between starting the project and now to make the bike not run, and I'd love to know what it is.

As I said, when I started doing this job I had the cam chain tensioner out, and turned the crank by hand a few times. All of this really does have the smell of the cam chain being off, and Bill has me really believing this. I want to believe that's why cylinder number 1 is so high. So here's what I did to check and double check the cam timing, and believe me I hope somebody says (lovingly if they ever want baked goods) Look ninny, you missed a step go do it again.

First I rotated the crankshaft so that the number 1 arrow is pointing straight ahead directly at the front gasket face, the area next to the tach drive. The T mark for cylinders 1 and 4 on the advance mechanism is lined up with the timing mark under the breaker plate (with no slack down the front of the chain between the exhaust cam sprocket and the crankshaft sprocket). If I understand correctly, this is what I want. It means the exhaust cam is properly timed. Step two, I removed the idler from the head revealing the entire top run of the cam chain. I counted the pins between the number two arrow on the exhaust cam and the number three arrow on the intake cam. Starting with the pin directly over the number two mark I counted twenty (20) pins; pint number 20 being directly over the number 3 mark on the intake cam. I counted several times, I did not miscount. According to what I understood from the manual this is exactly what I want, 20 pins means the intake cam is properly timed. The reference seems to be starting from the crankshaft, up the front of the chain to the exhaust cam, back to the intake cam. These distances must be precise; the run from the intake cam down the back of the engine to the crankshaft is taken care of by the tensioner. This is the way I bolted everything back together. Again if I did something wrong please tell me because I'd love to go out there and change the cam timing and have the bike run again.

As far as the carbon on the number two exhaust valve, I did a little banging with a plastic toothbrush handle today, to no avail. I'm not quite done trying that though, I'd like to find something a little sturdier to bang with. I also switched the shim from a 2.70 down to a 2.65 to see if I could relieve the clearance a little - still tight, and still no compression.

I also may be a little hasty with the assumption that it MUST need rings right now, though it seems obvious there is some wear there. I think ideally it would be good to get all the valve clearances within spec, solve the mystery with the cam timing, and take another set of compression readings.

Bill you're right sleeping and thinking is good, that's why I didn't mess with it too much today.

I sincerely thank you all for your interest, patience, ideas and advice. It's hard to do those things when you can't see the bike I imagine. Sooner or later someone will hit on it and the bike will at least run again, because it ran before.

Gnight,

Allie"Men will never be free until Mark learns to do The Twist."

-Denis D'shaker

79 GS750N

Comment

-

almarconi

almarconi

First start by holding the front of the timing chain and rotating the crank so that the T mark on the 1-4 side aligns with the timing mark. Install the exhaust cam so that the 1 on the cam sprocket is aligned with the edge of the cylinder head. Hold the cam in that position and pull up the chain, removing the slack, engage the timing chain with the sprocket. The number 2 on the cam sprocket should be pointing straight up. The pin that is aligned with the #2 will be the first pin, count 20 pins from there. Install the intake cam so that the #3 on the intake cam is aligned with pin #20. Do not rotate the engine until the bearing caps are installed. Make sure the timing marks are still aligned. You can now install the tach gear, idler and tensioner.First I rotated the crankshaft so that the number 1 arrow is pointing straight ahead directly at the front gasket face, the area next to the tach drive. The T mark for cylinders 1 and 4 on the advance mechanism is lined up with the timing mark under the breaker plate (with no slack down the front of the chain between the exhaust cam sprocket and the crankshaft sprocket). If I understand correctly, this is what I want. It means the exhaust cam is properly timed. Step two, I removed the idler from the head revealing the entire top run of the cam chain. I counted the pins between the number two arrow on the exhaust cam and the number three arrow on the intake cam. Starting with the pin directly over the number two mark I counted twenty (20) pins; pint number 20 being directly over the number 3 mark on the intake cam. I counted several times, I did not miscount. According to what I understood from the manual this is exactly what I want, 20 pins means the intake cam is properly timed. The reference seems to be starting from the crankshaft, up the front of the chain to the exhaust cam, back to the intake cam. These distances must be precise; the run from the intake cam down the back of the engine to the crankshaft is taken care of by the tensioner. This is the way I bolted everything back together. Again if I did something wrong please tell me because I'd love to go out there and change the cam timing and have the bike run again.

Comment

-

But... then it would look exactly as it does now, wouldn't it? I'd be taking it apart and putting it back together in exactly the same position as I already have, wouldn't I?Originally posted by almarconi View PostFirst start by holding the front of the timing chain and rotating the crank so that the T mark on the 1-4 side aligns with the timing mark. Install the exhaust cam so that the 1 on the cam sprocket is aligned with the edge of the cylinder head. Hold the cam in that position and pull up the chain, removing the slack, engage the timing chain with the sprocket. The number 2 on the cam sprocket should be pointing straight up. The pin that is aligned with the #2 will be the first pin, count 20 pins from there. Install the intake cam so that the #3 on the intake cam is aligned with pin #20. Do not rotate the engine until the bearing caps are installed. Make sure the timing marks are still aligned. You can now install the tach gear, idler and tensioner."Men will never be free until Mark learns to do The Twist."

-Denis D'shaker

79 GS750N

Comment

-

almarconi

almarconi

What I am suggesting is that you remove the cams and start over. From your description, it sounds like the cams were in place when you rotated the crank. I would not have rotated the crank with the tensioner removed.

Just out of curiosity, when the timing mark is aligned with the T, where is the location of the #1 piston? Is it at the top of the stroke, bottom of the stroke, or somewhere in between. You can remove the #1 plug to see the top of the piston.

Comment

-

Do some obsevations before disassembly…

With just the cam and crank end covers off you can rotate the crank slowly and see when the cams open and close the valves in relation to all the timing marks and piston movements. You're looking for anomalies or nonsense in any of the movements.

Bill1982 GS1100G- road bike

1990 GSX750F-(1127cc '92 GSXR engine)

1987 Honda CBR600F Hurricane

Comment

-

Skateguy50

Skateguy50

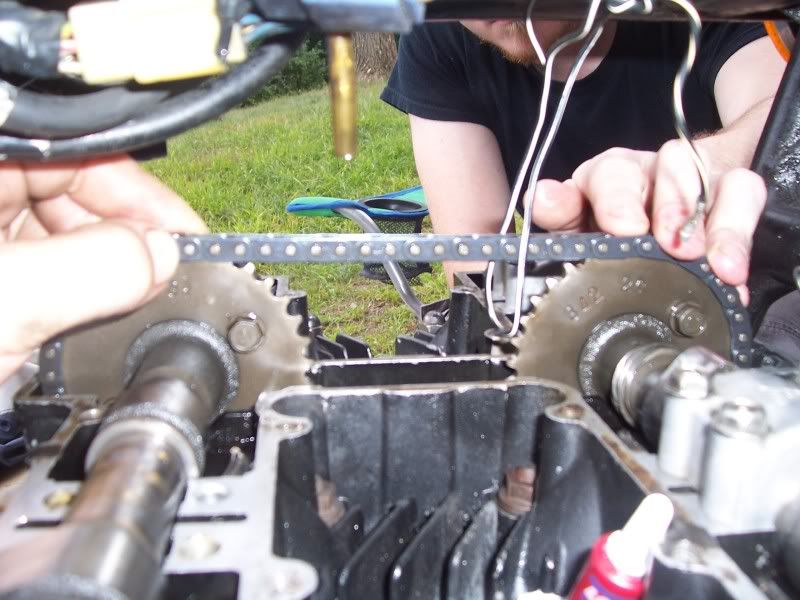

Hey Allie, I just did this last night and I will tell you an extra set of hands is very important for this to stay where it should. The step he is trying to point out is to removed the chain from the exhaust cam and be sure to pull all the tension up the front and over the cam. It could appear to be timed but be off by a link if you missed that step. I could not snap a good picture of the top dead center mark through the view window but here is the top of mine...Originally posted by Allie View PostBut... then it would look exactly as it does now, wouldn't it? I'd be taking it apart and putting it back together in exactly the same position as I already have, wouldn't I?

The slower you redo this process the better, also follow the steps carefully for resetting the tension. I recall after its all torqued down you turn it a few times and recheck the positions then, turn the engine counterclockwise slowly while turning the knob slowly counterclockwise on the tensioner, then release and turn the engine regular again.

Also Steve's suggestion of tapping the top of the valves to reseat them is much easier with the cams off. You would want to remove the shim and bucket and tap the valve in the center with a large wood dowel or block, if you use say a socket and hit the part around the valve in the center you would likely pop out the keepers and have to take the head off to reinstall the valves. So be sure you are hitting the actual top of the valve (center piece under the buckets)

So just for the sake of being able to really push in the valves and let the springs seat them better it might be worth repeating this procedure... and if you can get a set of hands to keep the chain tight and in positions its a HUGE help.Last edited by Guest; 08-18-2010, 08:17 AM.

Comment

-

Well it looks as though those cams are coming off - hey I wanted to learn, I guess I got my wish. Yes it sure would be nice to be able to smack straight down on those valves. And even though nothing is visibly off with the cam timing something still has to be off, there's really no other explanation is there?

With the T mark for 1-4 aligned, by the way, pistons 1 and 4 are at TDC, 2 and 3 are at BDC (is there such a term?). I also notice the cams look quite symmetrical - the lobes on the exhaust cam point as follows: 4 straight ahead, 3 straight up, 2 straight down, 1 straight back. The intake lobes are a mirror image - 4 straight back, 3 straight down, 2 straight up, 1 straight forward. How does that sound to you engine geeks? It sure looks cool to me, and may even be a manifestation of the metaphysical underpinnings of appliantology.

I was thinking of taking the head off for a peek while the cams are off, but maybe I'll just do the cams first and see what happens. It was probably unwise of me to even pop the valve cover while I did the intake stuff, I like doing one thing at a time and recording results much better. It may take longer but it's more thorough."Men will never be free until Mark learns to do The Twist."

-Denis D'shaker

79 GS750N

Comment

-

Skateguy50

Skateguy50

wish i snapped a better pick but from what I can see in mine those cam positions are roughly correct.

You can do it, I was without the GS for 2 and a half weeks but its buttoned up and fired right up tonight. Felt great to get a ride after all that work getting it going, YOU will have your ride soon just keep the wrenches turning.

Comment

-

SteveN

SteveN

Does the 79 have points? if the cam chain tensioner was off might be worth a look and make sure the points are opening at the right time. I'm lazy and check the easiest stuff first. That's also why I have twins instead of 4 cyl.

Comment

-

Fudge…

You're right, each step compounds the variables of the previous step. I'm no longer bold about rebuilds. Going forward I'll wait for good running bikes, before I buy. No more “Learning Experiences” if I can avoid them.Originally posted by Allie View PostI was thinking of taking the head off for a peek while the cams are off, but maybe I'll just do the cams first and see what happens. It was probably unwise of me to even pop the valve cover while I did the intake stuff, I like doing one thing at a time and recording results much better. It may take longer but it's more thorough.

Taking the head off will allow you to examine the ignition chambers, the valves from all sides, and the piston rings. I think the rings are fine. It could be you bent a valve.

However a new head gasket will be $100. You are a musician, right? Hope nothing has to go on Ebay.

Hope nothing has to go on Ebay.

Bill1982 GS1100G- road bike

1990 GSX750F-(1127cc '92 GSXR engine)

1987 Honda CBR600F Hurricane

Comment

-

Skateguy50

Skateguy50

Totally, start with just the cams and give the top of the valves a good hit to rebound and set. However watch the TDC marks and make sure you do 2and3 with 1-4 tdc.

Also if you did not remove the cams you would not really be able to pull the tension off the chain to set that exhaust cam. If it slipped a notch you need to remove them to reset the chain, at the very least the intake cam to get the slack.

Putting it all together after that step saves you the $150-$200 in gaskets taking a peak one level lower will cost you, so its definitely worth the time to see if that's enough to get you rolling again.

Comment

.png)

Comment