As I was disassembling the new (to me) set, I discovered that 3 of the 4 mixture screw were broken off in the carb bodies. GRRRRRRR.

Anyway, I devised a plan to fix 'em.

First, I modified one of the broken screws to use as a guide for drilling out the broken

tips.

I machined the ends off & drilled a .025" hole completely through the screw & slotted one end for a screw driver.

Next, I turned a spud to a slip fit in the throat of the carb. Tapped it 1/4 NPT & then made some quick & dirty cuts with the bandsaw.

Back into the lathe, with the pipe plug screwed into the spud to spread the "fingers". Now the part will be parallel to the bore when the carb is fitted onto the spud, & the plug tightened.

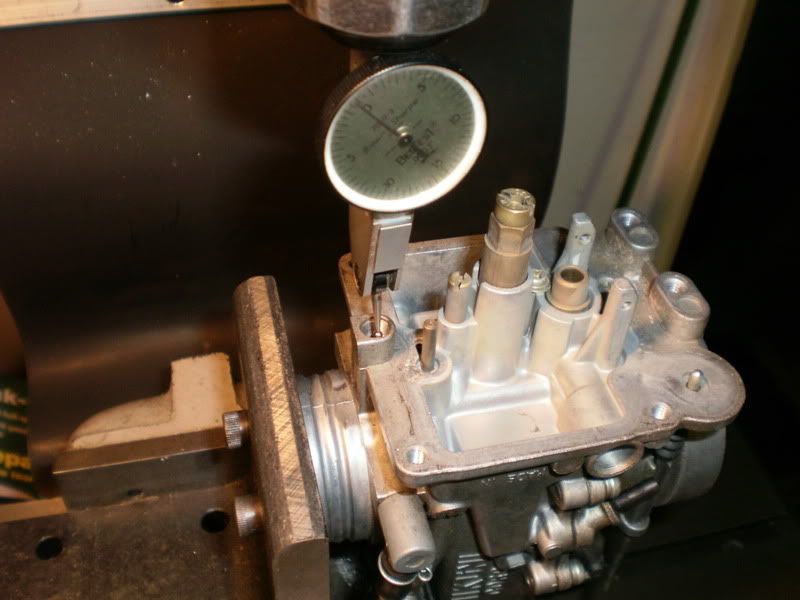

Bolted the spud to a small angle plate on the mill.

Using a gauge pin to ensure the carb body is properly located in both the "X" & "Y" axis.

Finding the center line of the hole. Even though I am using the previously made bushing as a guide, I still want to keep everything a accurately aligned as possible.

A few thousandths mis alignment will be compensated for by the bushing, so a bit of error is allowable.

Once I had everything all locked down & secure, I installed my little guide bushing & drilled out the broken tip.

The bushing is screwed down into the hole, & keeps the drill centered & won't let it flex & wander.

Worked like a charm. The first carb body took about 30 minutes to get all set up and fixed. The other two took all of 5 minutes each since I had the steps all worked out.

Now I can re-assemble the carbs with new O-rings, gaskets & of course brand new mixture screws.

Enjoy.

.png)

I did some machinery work back in high school, but I was never very good at it. Pretty cool to see someone with the machinery fixing something that would stump most everyone else.

I did some machinery work back in high school, but I was never very good at it. Pretty cool to see someone with the machinery fixing something that would stump most everyone else.

Comment