Ive got some MP-50 soaking in there but what are my options if I can not get them out?

Announcement

Collapse

No announcement yet.

2 pilot screws wont come out

Collapse

X

-

AlTheKiller

AlTheKiller

2 pilot screws wont come out

In the middle of re-jetting and ive got two pilot screws that refuse to budge. Its looking like someone was into the carbs not long ago and did a half assed job re-jetting and tried to get these two out (some what stripped the tops) then gave up and just did the other two.

Ive got some MP-50 soaking in there but what are my options if I can not get them out?Tags: None

-

koolaid_kid

koolaid_kid -

cableguy

cableguy

Maybe you've tried this already, but sometimes if the slots aren't totally shot grind down the tip of your screwdriver so that the tip fits exactly into slot. I think half the strip-outs happen because a thin screwdriver can't fill up the slot. After that it's drill time baby.

Comment

-

AlTheKiller

AlTheKiller

the screw driver fits nice and snug and id rather not grind down a snap on screw driver haha. but if I have to ill find a cheap screw driver and go that route.

so it is possible to drill them out? any links off hand to a new set? ill go look around now too

Edit: nevermind. Ive got three extras. Ill probably just drill them outLast edited by Guest; 03-15-2012, 07:08 PM.

Comment

-

Propane torch and heat the dog snot out of them...then a few drops of oil or a squirt of penetrating oil will usually loosen them up. If they move then work them back and forth with another dose of oil to work it in there.MY BIKES..1977 GS 750 B, 1978 GS 1000 C (X2)

1978 GS 1000 E, 1979 GS 1000 S, 1973 Yamaha TX 750, 1977 Kawasaki KZ 650B1, 1975 Honda GL1000 Goldwing, 1983 CB 650SC Nighthawk, 1972 Honda CB 350K4, 74 Honda CB550

NEVER SNEAK UP ON A SLEEPING DOG..NOT EVEN YOUR OWN.

I would rather trust my bike to a "QUACK" that KNOWS how to fix it rather than a book worm that THINKS HE KNOWS how to fix it.

Comment

-

AlTheKiller

AlTheKiller

im sending the lady to go pick up a torch.

the PO left all sorts of new parts apparently. enough that I no longer care about the state of the ones that are in the carbs, I just need to get them out now haha.

Thanks for all the help guys. I really appreciate it

Edit: one last question, can I drill out the pilot jets too?? Ive got 4 new ones and these are in the same boat as the pilot screws.Last edited by Guest; 03-15-2012, 07:58 PM.

Comment

-

cableguy

cableguy

That might be the last time she asks you if you need anything while she's out. You were specific about the variety I hope (propane, butane, MAP, tiki, flashlight if she's british, olympic)Originally posted by AlTheKiller View Postim sending the lady to go pick up a torch.

Brass can drilled easily but as soon as you so much as touch the bit to the threads you've got a bigger problem. Better off with whatever heat source your wife brings you and work it slow.

Comment

-

AlTheKiller

AlTheKiller

She brought back a butane torch. should work i hope. Im done for the day though so i sprayed more MP-50 onto everything then ill try tomorrow while at work.

Comment

-

thkbaron

thkbaron

Althekiller............

So I hope you don't have this problem. I just ran into the same exact problem you are having with your pilot jets. I am most certain I caused my problem. I have a jet that won't back out. My bike is running just fine but I knew that I had a sticky jet so I wanted to back it out and clean it so it would twist smooth. Of course it stuck and like a moron, I tried to press hard and only managed to strip the head out. I left the carbs on the bike and it's the hardest jet to get straight at. Anyways, what I think I did was messed up the threading on the side of the (port wall if you want to call it that) so I can't back it up due to poor threading. I hope that's not the case with you, but I know it is with mine. I was going to try and drill it, but just left mine seeing that it runs fine. Let me know how everything goes with your project and how you get them out.

Comment

-

AlTheKiller

AlTheKiller

I don't believe the threads on the walls are messed up but it is entirely possible as someone before me has tried to take them out before. I do have a tap and die set but not sure if there is one specific for this application. I'll keep you all up dated through out the day.

Comment

-

If you are simply re-jetting, the pilot jets are usually OK, unless you have gone all-out Gonzo on cams, pistons, etc. that REALLY changes the breathing capability of the engine.

However, if you are doing a full CLEAN of the carbs along with the jetting, removing all the jets is a good idea.

HOWEVER, ... my guess is that you are not dealing with "pilot jets" at all.

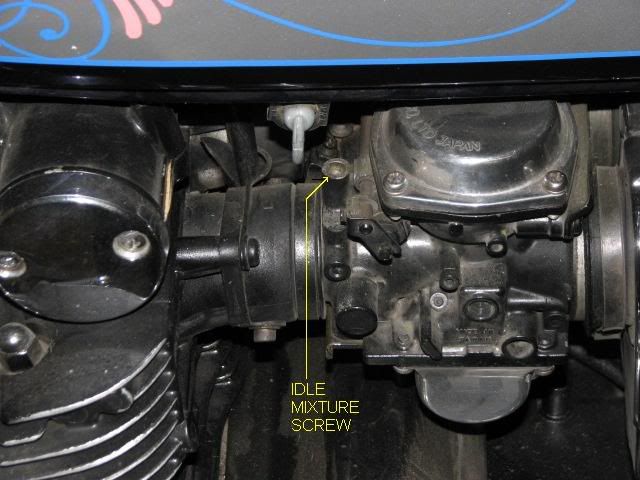

My guess is that you are trying to remove the IDLE MIXTURE ADJUSTMENT SCREWS.

Am I right?

Again, they don't need to be removed for re-jetting, but they do need to be adjusted when it's all done, and the little o-rings down near the tip should be replaced in the course of cleaning and re-habbing the carbs.

.sigpic

mine: 2000 Honda GoldWing GL1500SE and 1980 GS850G'K' "Junior"

hers: 1982 GS850GL - "Angel" and 1969 Suzuki T250 Scrambler

#1 son: 1986 Yamaha Venture Royale 1300 and 1982 GS650GL "Rat Bagger"

#2 son: 1980 GS1000G

Family Portrait

Siblings and Spouses

Mom's first ride

Want a copy of my valve adjust spreadsheet for your 2-valve per cylinder engine? Send me an e-mail request (not a PM)

(Click on my username in the upper-left corner for e-mail info.)

Comment

-

AlTheKiller

AlTheKiller

yeah thats what I am having troubles with currently. For some reason the walk through I was using was calling them pilot screws :dunno:

And yes I am doing a full clean and check of everything while re jetting and I saw that you use those to adjust the carbs when all is done and them not budging is a problem.

I did get an extractor kit today from Snap On but the screws are not brass and are extremely tough to drill in to. Im hoping to have more luck with getting them out tomorrow while at work.

also one other thing I noticed while cleaning everything up, is that the float seat that is in my carbs looks a bit different than the one showed in the tutorial. Instead of having the round mesh, its just flat and straight. Is that normal? or did the OP put something in there that isnt suppose to be?

also, with the DynoJet jet kit they want you to drill out the slide lift hole. Before I drill something I want to make sure Im drilling the right thing. Its the cylinder that has the rubber diaphragm on it along with the needle? so not the center hole where the needle goes but the one off to the side correct?

Edit: here are the old parts (Left) the PO replaced with the ones that are in the carbs now. Brand new needle and seat on the right.

the ones that are in the carbs do not have the half circle mesh, but a style of mesh that sits flush across the opening. Is that bad? Should i switch out the mesh screens or even the needle seats themselves?Last edited by Guest; 03-16-2012, 09:14 PM.

Comment

-

Sorry about that, it's a rather unfortunate, and common, mistake.Originally posted by AlTheKiller View Postyeah thats what I am having troubles with currently. For some reason the walk through I was using was calling them pilot screws :dunno:

You only use them for adjusting the mixture. Synchronizing the carbs is done with the adjusted on the throttle shaft between the carbs.Originally posted by AlTheKiller View PostAnd yes I am doing a full clean and check of everything while re jetting and I saw that you use those to adjust the carbs when all is done and them not budging is a problem.

The two adjustments are commonly done together, but neither one replaces the other.

Before you get too far along with your drilling and mangling, get out your Dremel tool and a large cut-off wheel. Cut a slot down the tower and cut a fresh slot in the top of the screw. You should then have a good "bite" on the screw and can remove it. Don't worry about the slot in the tower, it's all in an area where it doesn't matter.Originally posted by AlTheKiller View PostI did get an extractor kit today from Snap On but the screws are not brass and are extremely tough to drill in to. Im hoping to have more luck with getting them out tomorrow while at work.

Not the best shot, but if you look closely, you can see that both carbs have had slots cut to get the mixture screws out.

If the flat screens look fine enough to be the filters they are supposed to be, they should be no problem. If you are not comfortable with them, move your round ones over to the new seats. They just clip right off.Originally posted by AlTheKiller View Postalso one other thing I noticed while cleaning everything up, is that the float seat that is in my carbs looks a bit different than the one showed in the tutorial. Instead of having the round mesh, its just flat and straight. Is that normal? or did the OP put something in there that isnt suppose to be?

That is correct, they want you to drill the holes that are off-center in the bottom of the slide. Do yourself a favor before you drill.Originally posted by AlTheKiller View Postalso, with the DynoJet jet kit they want you to drill out the slide lift hole. Before I drill something I want to make sure Im drilling the right thing. Its the cylinder that has the rubber diaphragm on it along with the needle? so not the center hole where the needle goes but the one off to the side correct?

Put a piece of wire or a smaller drill bit through the hole and notice that IT IS NOT DRILLED STRAIGHT, IT IS AT AN ANGLE.

.sigpic

mine: 2000 Honda GoldWing GL1500SE and 1980 GS850G'K' "Junior"

hers: 1982 GS850GL - "Angel" and 1969 Suzuki T250 Scrambler

#1 son: 1986 Yamaha Venture Royale 1300 and 1982 GS650GL "Rat Bagger"

#2 son: 1980 GS1000G

Family Portrait

Siblings and Spouses

Mom's first ride

Want a copy of my valve adjust spreadsheet for your 2-valve per cylinder engine? Send me an e-mail request (not a PM)

(Click on my username in the upper-left corner for e-mail info.)

Comment

-

AlTheKiller

AlTheKiller

Originally posted by Steve View PostSorry about that, it's a rather unfortunate, and common, mistake.

You only use them for adjusting the mixture. Synchronizing the carbs is done with the adjusted on the throttle shaft between the carbs.

The two adjustments are commonly done together, but neither one replaces the other.

Before you get too far along with your drilling and mangling, get out your Dremel tool and a large cut-off wheel. Cut a slot down the tower and cut a fresh slot in the top of the screw. You should then have a good "bite" on the screw and can remove it. Don't worry about the slot in the tower, it's all in an area where it doesn't matter.

Not the best shot, but if you look closely, you can see that both carbs have had slots cut to get the mixture screws out.

If the flat screens look fine enough to be the filters they are supposed to be, they should be no problem. If you are not comfortable with them, move your round ones over to the new seats. They just clip right off.

That is correct, they want you to drill the holes that are off-center in the bottom of the slide. Do yourself a favor before you drill.

Put a piece of wire or a smaller drill bit through the hole and notice that IT IS NOT DRILLED STRAIGHT, IT IS AT AN ANGLE.

.

thank you so much for all the help and quickly too!

I did notice that I will not be able to drill straight. What I plan on doing is putting the slide in a vice (carefully with rags to prevent messing up the slide) and angling the slide so the hole is "straight" to help prevent me from drilling it incorrectly. No idea if thatll work but figured Id give it a look tomorrow.

also I will try the dremel approach tomorrow. Ive got a nice big cut off wheel that should do the trick

Comment

.png)

Comment