650 head:

Port diameter: 42mm

Space between 1/2, 3/4: 44mm

1/2, 3/4 Center to center: 86mm

Space between 2/3: 68 mm

2/3 Center to center: 110mm

Center to center measurements obtained by math not measurement

Notes:

- Ports 1 and 4 are not perpendicular to the block they are angled slightly outward.

-Exhaust collar bolt pattern alternates; 1+3 the bolts are 2 o'clock and 8 o'clock, 2+4 are 10 o'clock and 4 o'clock

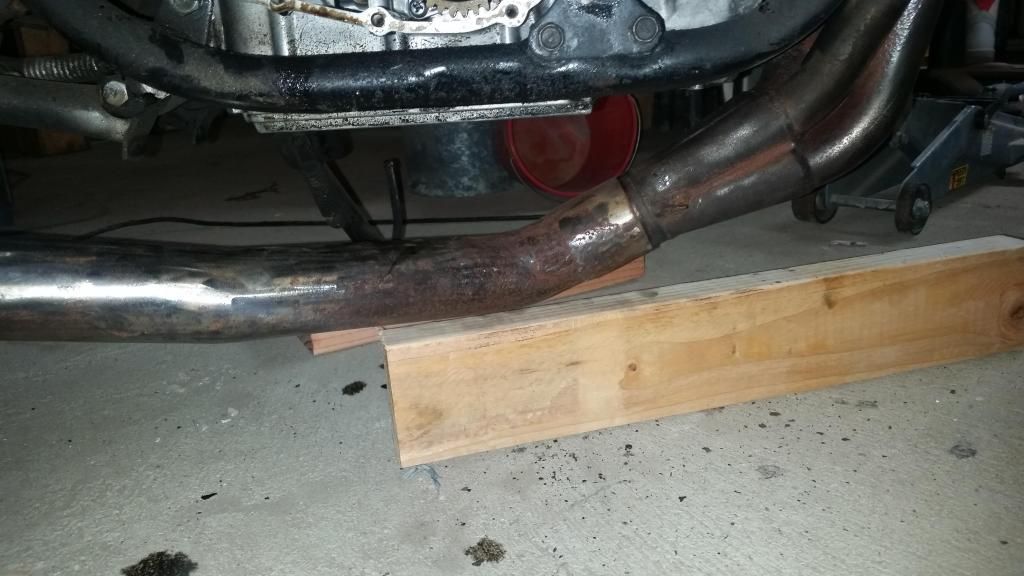

Kat 600 header:

Diameter: 38mm flared to 42mm at end. Actual pipe OD 36mm.

Spacing 1/2, 3/4: 50.5mm, 48.5mm (old pipe possibly bent)

1/2, 3/4 Center to center: 92.5mm, 90.5mm

Spacing 2/3: 72mm

2/3 Center to center: 114mm

Notes:

- pipes 2+3 slightly lower and slightly out.

- Exhaust collar bolt patterns do NOT alternate, 1+2 2 o'clock and 8 oclock, 3+4 10 and 4.

The Kat header is wider by 4-5mm at every port, 15mm overall. I know what you're thinking, "5mm is nothing! Muscle that suckered in", easy popeye; I did. However it took a LOT of muscle, there's no way I'd run it like that. I am optimistic with some gentle bending it will work. Seems to clear the oil pan and even the oil filter. Time will tell, I'll throw up some pics if I work it out.

I'll also add that 36mm (OD of pipes) is the port diameter of the 550 which shares the center to center port spacing of the 650 head, someone with some welding skill could probably cut and weld some new ends on and make it work for a 550.

.png)

Comment