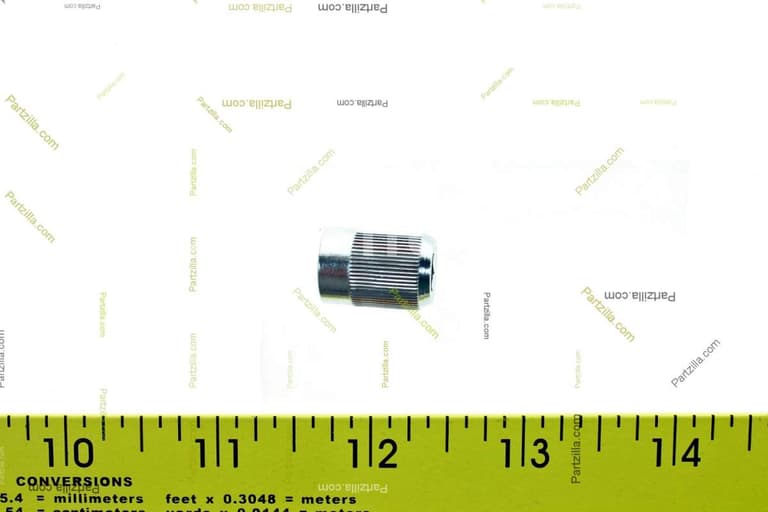

This is what they look like:

Announcement

Collapse

No announcement yet.

Exhaust bolt replacement?

Collapse

X

-

Exhaust bolt replacement?

I recently got a 77 750B and I plan on keeping it. I think I will eventually need or want to remove the exhaust for one reason or another. I am considering soaking the bolts for a week or so with PB blast and giving it a go or leaving them alone and try to remove them when I have to. I plan on replacing them with studs or use stainless bolts and anti-seize. I just imagine they will get more corroded if I wait but by how much is anybody's guess. Looking for advice.

This is what they look like:1977 GS750BTags: None

-

Forum GuruPast Site Supporter

Super Site Supporter- Jun 2018

- 5768

- Mifflinburg, PA / Land of Tar & Chip

A soak in PB certainly wont hurt. Others have suggested a better penetrating oil is Kroil (no experience). Some have suggested an ever-so-slight tightening motion, before turning counter-clockwise. I don't know if that works or not. I, like so many others, have dealt w/ broken exhaust bolts. From the looks of the outside, you should definitely use something. I now use Stainless Steel Allen Head bolts from the hardware store, w/ anti-seize on the treads, and have no issues. I do re-check the torque every few hundred or 1000 miles.Last edited by Rich82GS750TZ; 11-09-2021, 11:56 AM.Rich

1982 GS 750TZ

2015 Triumph Tiger 1200

BikeCliff's / Charging System Sorted / Posting Pics

Destroy-Rebuild 750T/ Destroy-Rebuild part deux

-

Good to be thinking ahead, like others I've been there done that. No doubt best penetrating oil you can think of, for a while, & then possibly a socket on a drill-driver or 1/4" impact driver set low so it can hammer (vibrate) on the bolt instead of just muscling it out. Going back on, studs to replace the bolts & plenty of anti-seize.1983 GS1100E, 1983 CB1100F, 1991 GSX1100G, 1996 Kaw. ZL600 Eliminator, 1999 Bandit 1200S, 2005 Bandit 1200S, 2000 Kaw. ZRX 1100

Comment

-

Yes^^per these guys. Start now with the oil. Be aware you can get behind the collars to oil where the bolts and the thread enters engine, but you need it in the collars too. Get a bright flashlight and your head in there and I think you'll see.. I just used ATF mixed with paint-thinner as penetrating oil (acetone is what's supposed to be better mixed but...)

Tap away at the rust and the collars. A bit of vibration is good. There's no thread in the collars so there has to be a place for oil in there to work at any binding rust.

...and I impacted them both ways...while I was oiling and then a bit harder when I came to thinking it was time to gird my loins and get them actually off :ie: if you get a bit of a motion loosened, tighten it in again, then out, then in, etc etc with copious oil and time for it to penetrate each time. I've done 4 bikes this way without the Big Disaster...need say that one was a Honda with stud and nut and the nut didn't come off-the stud turned out- so I'm not sure of the advantage of stud and nut anymore except that they are easier to find than the Hi-strength OEM Suzuki bolt? Do be sure a stud or bolt is hi-strength. I considered making a stud for the Honda but rejected it on that basis.

I don't know about stainless. ...On boats, it can be an especial horror threaded into aluminum. But once bit twice-shy.Last edited by Gorminrider; 11-09-2021, 11:40 AM.

Comment

-

Forum LongTimerGSResource Superstar

Past Site Supporter

Super Site Supporter- Mar 2006

- 35853

- Torrance, CA

It's absolutely critical that you don't use too much force on those screws because they just love to break off. Soaking in penetrating oil is a good idea. It would be even better if you spray them down while the engine is hot, or use a torch to heat them up good and hot before spraying. Use a short handle ratchet wrench, a 1/4" drive is a good idea. If the screws don't turn out easily work them both ways, tighten and loosen until you get them to crack loose. Once you get them to move hit them with more spray and heat and rock the bolt back and forth, tighten/loosen, until you are finally able to get them out. Take your time and never force them...consider this your warning. Ed

Ed

To measure is to know.

Mikuni O-ring Kits For Sale...https://www.thegsresources.com/_foru...ts#post1703182

Top Newbie Mistakes thread...http://www.thegsresources.com/_forum...d.php?t=171846

Carb rebuild tutorial...https://gsarchive.bwringer.com/mtsac...d_Tutorial.pdf

KZ750E Rebuild Thread...http://www.thegsresources.com/_forum...0-Resurrection

Comment

-

Yes, that's true.. And with a stud and nut a body might even split the nut off too if you could get at it with a dremel or hacksaw. But I thought it was worth a mention. The corrosion was apperently worse at the nut than at the block. I made a reckless effort take a nut off a (Honda) stud once removed and it snapped off.

Comment

-

oh, and still on that, do try to match the threaded length of the stud with the bolt you remove engine side. Like wise, match the UNTHREADED portion up to the original Suzuki bolt head...that is, I'd avoid having thread where it didn't need to be between collar and motor and inside the collar.. Thread is little weaker and more corrosion prone when next you want to remove the pipes. Of course you can cut extra off but you might need to cut some more threads too, depending on what studs you can buy. This might take stainless off the option list as it's harder to thread? or ruins a tool? not sure...I plan on replacing them with studs

It's a bit of thought and or trouble but just might be worth it down the road or, for the next guy.Last edited by Gorminrider; 11-09-2021, 01:28 PM.

Comment

-

Ayuh.... patience is your friend.Originally posted by Nessism View PostIt's absolutely critical that you don't use too much force on those screws because they just love to break off. Soaking in penetrating oil is a good idea. It would be even better if you spray them down while the engine is hot, or use a torch to heat them up good and hot before spraying. Use a short handle ratchet wrench, a 1/4" drive is a good idea. If the screws don't turn out easily work them both ways, tighten and loosen until you get them to crack loose. Once you get them to move hit them with more spray and heat and rock the bolt back and forth, tighten/loosen, until you are finally able to get them out. Take your time and never force them...consider this your warning.

I will just add that if you absolutely must break one, DON'T break one next to the frame."Men will never be free until Mark learns to do The Twist."

-Denis D'shaker

79 GS750N

Comment

-

I pray that doesn't happen. I've read a number of things about penetrants and they are all over the place and so I may just go with (cheap) Liquid Wrench liberally applied, some strategic tapping with a hammer, possibly heat, and careful wrenching. Tomorrow I will pick up some Liquid Wrench and start the process. Wish me luck.1977 GS750B

Comment

-

Good luck and welcome to the site. If something does get stuck, I think the torch may turn out to be your best friend.Originally posted by oldskull View PostI pray that doesn't happen. I've read a number of things about penetrants and they are all over the place and so I may just go with (cheap) Liquid Wrench liberally applied, some strategic tapping with a hammer, possibly heat, and careful wrenching. Tomorrow I will pick up some Liquid Wrench and start the process. Wish me luck. 1982 GS1100E V&H "SS" exhaust, APE pods, 1150 oil cooler, 140 speedo, 99.3 rear wheel HP, black engine, '83 red

1982 GS1100E V&H "SS" exhaust, APE pods, 1150 oil cooler, 140 speedo, 99.3 rear wheel HP, black engine, '83 red

2016 XL883L sigpic Two-tone blue and white. Almost 42 hp! Status: destroyed, now owned by the insurance company. The hole in my memory starts an hour before the accident and ends 24 hours after.

Comment

-

I've had good success with both a torch and ice spray. Hot/Cold cycling is your friend, though it must be noted this is happening to the exhaust bolts anyway ��

Hot engine is a good call, you want the threaded portion of the bolt moving, not its head.#1: 1979 GS 550 EC "Red" – Very first Bike / Overhaul thread New here? ☛ Read the Top 10 Newbie mistakes thread

#2: 1978 GS 550 EC "Blue" – Can't make it a donor / "Rebuild" thread Manuals (and much more): See Cliff's homepage here

#3: 2014 Moto Guzzi V7 II Racer – One needs a runner while wrenching

#4: 1980 Moto Guzzi V65C – Something to chill

Comment

.png)

Comment