Announcement

Collapse

No announcement yet.

Electrical mods - confirmed working

Collapse

X

-

Forum Apprentice

- Dec 2018

- 63

- Grew up in (very) rural North East Texas; Now live in sunny Carlsbad, CA (near San Diego)

Best Regards,Originally posted by Who Dat? View PostI have a few questions/comments, They will be inserted in a shortened quote of your post.

Hi Who.. First off.. WOW!!! Thank you for you very detailed writeup. Im very impressed with your attention to detail. These types of exchanges are where data is truly turned into information. You have enlightened me on my understandings.

See replies below, inline

1) updated my R/R with an OEM mosfet R/R. Whose "OEM" did you use? Suzuki never had a MOSFET R/R, and any MOSFET unit is merely an update, not an actual upGRADE. [darrell said] Yes. Nessim schooled me on this. My (incorrect) assumption was that a MOSFET R/R meant Series R/R. Its not. I was using an Amazon special R/R. It seems to work ok, but i bought a SH775 from Nessim and i will be swapping that out this weekend.

1a) I will attach a pix on a FUP reply to this thread. What is a "FUP" reply? [darrell said] Sorry, this is IT lingo.. FUP = Follow UP.

2) Added a volt/ammeter to the console. ... and put the ring on the red wire coming directly off the R/R from above. Nice meter, have not see a combo unit like that. Note that your choice of sensor location will show LOT of amps, virtually all the time the bike is running. It will include whatever the bike is using, along with what is actually going to the battery. If you move it to the wire that attaches to the MAIN fuse, it will show only what is charging the battery. Years ago, I played with an ammeter and a voltmeter in my vehicles, decided to ditch the ammeter and keep the voltmeter. MUCH more informative. [darrell said] Humm. Let me better understand what you are saying.. So the current location of the ring is on the lead directly off the R/R. My thought in doing so was to measure the amps that the R/R is pumping into the battery. This entire mod (volt/ammeter) was caused by a failure i encountered on a ride where my bike died mid-ride due to a discharged battery. At the time, i was only doing short rides to test carb tuning. This was caused by a faulty connection between R/R and battery. This was user error as i originally connected the lead coming from battery to lead coming from R/R with one of those solder/heat shrink joints. The idea is that you just butt the wired together in the joint and then heat them up and solder and heat shrink makes a water tight connection. My conclusion on this type of connector is that you need to use a lighter to "close the deal" rather than a heat gun. The heat gun does not seem to heat up the solder enough. Obviously, i can hold the heat gun near the solder for a longer time, but that ends up melting the heat shrink. Bottom line, i screwed up this connection and it came loose and i didnt realize it until my battery was completely discharged. Thankfully i was close to home. Question: so you are saying to move the pickup ring to the load side of the main fuse? Could i just use the switched mains wire (that goes to the key) in the headlight? That would be a much shorter wire run and allow me to bury the pickup ring in the headlight instead of under the seat. Please confirm if my understanding is correct.

3) upgraded headlight to HID led. Which did you do, HID or LED? They are mutually exclusive terms for different types of bulbs. Looking at your link, it was an LED. Although it is a decent brand, it might not be the best replacement available. Please be sure to check the beam pattern on a wall AND on the road in front of you at night. Too many of the "lesser-quality" lights put light where it should not be. [darrell said] So I will plead ignorance on this one. This was an amazon purchase that had good reviews. The beam intensity is greatly increased and it is much more "directed" vs being scattered with bulb i had it in original. I will do some research on HID vs LED. Can you offer any suggestions of one vs the other? Is there a good reason to use one vs the other or is it mainly a personal preference?

3a) Note, you will also need to add some dummy load resistor to both legs (high and low beam) of the circuit. Technically, you would want to add enough dummy load to match what the incandescent bulbs were drawing. This should be about 50w for each circuit. Note, that my calculation this was specifically about 40w, however, Amazon did not sell 40w dummy load resistors; they only had 10w and 50w. Why would you possibly want to add resistors to your headlight circuit? (OK, saw you had an 1100E with the monitor panel. Only your 1100E and the similar 750E have that panel, so would be the only ones to "need" a resistor.) Next, were the resistors 10 and 50 WATTS or 10 and 50 OHMS? If they were rated in watts, what were their ohms? Again, mutually exclusive terms. Personally, I would have tried to modify the sensor for the dash monitor and leave full power to the light. [darrell said] They are 10 and 50 WATT respectively. See link below. So what i did was measure load (with multimeter with pickup ring) of both high and low beam leads using original headlight. Then did same test with new LED light. The delta was ~4A for each. ie the LED was drawing 4A less than original. using Watts = Amps * Volts, that comes out to 48Watts. So my assumption (very likely incorrect) is that i need to add ~48Watts of load to each leg to simulate same load. This does, indeed get rid of the idiot light on the dash. However, as i mentioned, these 50W resistors get HOT, HOT, HOT. I found that just adding a simple 10W resistor seems to solve the problem and these generate far less heat. I simply routed them outside of the headlight housing thus they get airflow when bike is moving. Please correct me if im wrong is any of my conclusions from above. The resistors did not cause any noticeable decrease in brightness in the light

50watt: https://www.amazon.com/gp/product/B0...?ie=UTF8&psc=1

10watt: https://www.amazon.com/gp/product/B0...1?ie=UTF8&th=1

4&5) replaced brake/tail light with LED that has a blink feature when you press/pull the brake. Basically it flashes about 3 times, then stays on full. Ive seen this on several bikes and its a great safety feature. Note, you will need to add another (i actually used 2 wired in series) 10w load resistor. Why do you need a load resistor here? The light is made to work with a 12-volt system, let it do its thing. [darrell said] the 10w load resistor is to solve same problem from above.. ie the idiot lights on the dash. Without them, my dash looks like a Christmas tree. Yes, i could have solved this other ways, but i dont like the idea of disconnecting a sensor just because it annoys me. I would rather give the sensor data that is within its tolerance thus it will still function normally, ie tell you when the bulb is burnt out.

6) The blinkers swap out for LED's is another story. Bottom line, i left these as incandescent bulbs because 1) they are working just fine, 2) they are bright enough and 3) my turn signal auto cancel is working just fine and i want to keep it that way. The turn signal LED topic is well documented on the forums. Probably the best thing, considering what you have done to the other circuits. Yes, it's possible to change to LEDs, but it does take some precise modifying. [darrell said] Yes. I do have some LED blinker bulbs that i tried. My understanding is that yes, it is possible, but from what ive read, it appears that (at a minimum) would require replacement of blinker relay with solid state device and some heavy mods to make the self cancelling unit continue to work. IMO the juice is not worth the squeeze on this one. Blinkers are bright enough and, call me old fashion, but i do get a certain amount of satisfaction out of watching the 40 yr old technology of the self cancelling device work in present day. The self cancelling circuit and the gear indicator on the dash are, IMO, the most technologically advanced features on the bike.

Again, Thank you very much for your input.

Darrell

Darrell

1983 GS1100ED (red) / 1983 GS1100ED (blue)

Comment

-

Tried quoting your post, then adding to it, as before, but the way you added your quotes to my quoted comments prevents that. So, ...

Thanks for the clarification on the R/R and "FUP".

I'm not in IT, so am not acquainted with the term.

Regarding ammeter sensor location:

The output of the R/R goes into the main harness and splits. One leg goes forward to the ignition switch, then back to the fusebox, where it provides power to run the bike. The other leg goes back through the MAIN fuse to charge the battery. If you place your sensor on the bottom leg (right near the R/R), you will simply be measuring ALL the current that the R/R is producing, but won't know if it's running the bike or charging the battery. If you move your sensor to the 'forward' leg, you will only be measuring the current that the bike requires for normal running. If you move it to the 'battery' leg, you will only measure the current that is going to (or coming from) the battery.

I mentioned earlier that I have found a volt meter to be more useful than an ammeter. Think of electricity as a fluid (gas or water), it's easier to visualize. The ammeter measures current flow, much like gallons per minute. The volt meter measures pressure, much like psi in a tank. More fluid in a tank, more psi. Now, consider this: while riding, and thinking of your fuel supply, would you rather know that you are using fuel at 2 gallons an hour or that you have 1/4 tank left? In the case of your electrical failure, you would have shown a large discharge on the ammeter, but would not have a clue if that happened on a fully-charged battery or if your battery was just about fully gone. Discharge rate would remain about the same. If you had a volt meter, seeing 12.5 volts or 11.0 volts would tell you how critical your situation is. Having both is great, but the volt meter tells you more at a single glance.

HID vs LED lights.

HID lights use a High-Intensity Discharge, which is basically an electric arc in a (usually) Xenon-filled envelope. They tend to be sensitive to input voltage and don't like to be turned on and off very many times. Having the light turn on when you turn on the key, then having the voltage dip considerably when you start the engine is just about as bad. Overall, some may have gotten away with one, but probably not a good idea on a motorcycle.

Once again, only your 1100 and its little brother 750 have those tattle-tail instrument panels. Converting the lights to a lower-draw LED sounds like a good idea, but then you are adding resistors to put the load back up to the point where the computer does not sense a problem. If your goal is to reduce load on the charging system, you have failed. If your goal was to have longer-lasting light bulbs, you might have succeeded, but some LEDs will fail if they don't have the correct power. When you added resistors, did you put them in-line with the light leads or across them, much like trying to add another light? Putting them in-line will reduce voltage to the lights, reducing their effectiveness. Putting them across the leads is the correct way, but they will get HOT, so mount them carefully.

I see now that the resistors for the brake/tail light are just to fool the computer, so I have to ask ... is it worth it?

LED turn signals are possible, but you need resistors for them, too, as well as a different flasher. If you install a different flasher, you will lose the self-cancel feature, as the Suzuki flasher is unique. There is nothing else in all of motorcycling or automobile use that will plug in (and work) without considerable modification. I have done that on my bike, but what I did would not work with all your sensors.If you're not living on the edge, you're taking up too much space.

Comment

-

Forum Apprentice

- Dec 2018

- 63

- Grew up in (very) rural North East Texas; Now live in sunny Carlsbad, CA (near San Diego)

Hello Who,

Once again, Thank You! for the detailed writeup. I absolutely cherish these types of exchanges. This is how we learn from masters like yourself. Your attention to detail cannot be more appreciated.

So based on your feedback, i swapped the sensor around (a few times) to see which i liked more. All have their plus'es and minus'es (no pun intended). In the end, i came back to my original requirement for installing the volt/am-meter combo in the first place; ie to detect a faulty charging system. Putting the pickup on either forward leg provides almost no "variability" in current since the electrical system is effectively static once you turn the key on. Obviously, it changes slightly when you go from high beam to low beam. Anyway, to your point, the ammeter does not tell you anything useful on that side other than what the total current draw is from the accessories. I ended up going back to the pickup on the R/R side. The readings fluctuate wildly (also as you predicted in your previous post). However, for me, this is exactly what im looking for. I get a warm fuzzy feeling when i look down and see that ammeter reading almost zero at idle and then zoom up to 16A when i accelerate. Provided that my battery is in working order, this give me peace of mind knowing that the R/R is charging the battery. Also, as you pointed out, the volt meter tells me if the battery is working based on output voltage.Originally posted by Who Dat? View PostRegarding ammeter sensor location:

I wired them across. The ones that i referenced from Amazon are specially made for hooking them up across. They have 4 separate bullet connectors; two male and two female. Basically, you just unplug both leads of the accessory you want to add load to and "shim" in the resistor.Originally posted by Who Dat? View PostWhen you added resistors, did you put them in-line with the light leads or across them

Yes, this was exactly my experience. As i mentioned in my original post, they get HOT, HOT, HOT. The little 10W ones are mounted inside of a piece of ceramic molding with a piece of heat shrink on the outside. They get warm-ish, but not really hot. I used these on the tail light/running light. The 50w ones, on the other had, get H-O-T, hot! They have a regular heat sink. I ended up using these on the headlight. Note: i did find that the 10w work just fine on the headlight to get rid of the idiot light on the dash. w/r to mounting location, i put the 50w ones on the outside of the headlight housing, just below the headlight, I tie wrapped one each to each fork such that the heat sink get plenty of air flow when bike is moving. One down side, is that i need to simulate airflow when bike is sitting in garage idling. I keep a fan in garage anyway for running airflow over engine when im idling anyway.Originally posted by Who Dat? View PostPutting them across the leads is the correct way, but they will get HOT, so mount them carefully.

I installed one of Ed's SH 775 as an upgrade several weeks back. Therefore, im no terribly concerned about reducing load on my charging system. The main reason i did the LED upgrades was for safety and visibility. The LED headlight (i checked, its LED) is just sooooo much brighter than the incandescent bulb. Yes, the beam is a bit more scattered than the incandescent bulb, but its just so bright that its not really a problem at night. The big advantage is during the day. Its just so much more visible. Anyway, that was the rationale for doing the headlight.Originally posted by Who Dat? View PostI see now that the resistors for the brake/tail light are just to fool the computer, so I have to ask ... is it worth it?

Now W/R to the tail light, again, this was done strictly for visibility. I ended up installing a LED brake light that has a "strobe" feature. It basically strobes about 4 times when you pull/press the brake and then settles into a solid red. I recorded a short YouTube video and included the link in my original post in case you have not seen these mods. Ive seen this mod on several bikes and it really increases the visibility. In many ways, its like the center brake light on cars. Its just something else to get the person behind you to notice you. There are just way to many people txting and driving these days and i want to be as visible as possible.

Now, to answer your question.. Is it worth it? I can say whole-heartedly, YES! Without a doubt.

Best Regards,

Last edited by darrell3001; 01-09-2023, 10:41 PM.Darrell

1983 GS1100ED (red) / 1983 GS1100ED (blue)

Comment

-

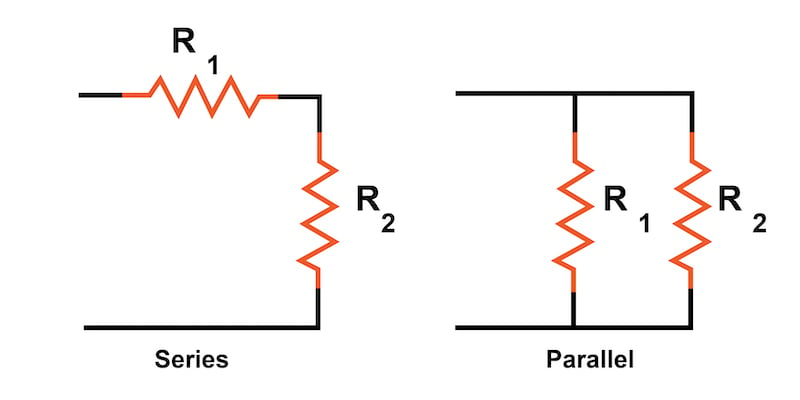

I do have one query, did you wire the big wattage resistors in series or in parallel with the head light wires. In a series connection, current stays the same, you're just making a huge voltage drop to heat up a resistor. In a Parallel circuit, the current is divided according to the resistance of each route, and this lower the amperage going to the bulb. The Resistors would not have heated up so much. Proof is when you dropped the resistance, your voltage regulator stopped working so hard, ass opposed to the series which had you R/R seeing a new massive load. Parallel decreases current flow, series connection creates a voltage drop, where you could mount an accessory, but does not change the current flow.

Comment

-

Forum Apprentice

- Dec 2018

- 63

- Grew up in (very) rural North East Texas; Now live in sunny Carlsbad, CA (near San Diego)

hi Suzukian .. I wired them in parallel. Just to be clear on my answer. The resistors came with a red and black lead from the resistor itself, then each lead split off into a male and female bullet. I unplugged the + wire on the high beam and connected the red bullets from the resistor to each end of the disconnected main leads. I did same with black bullets on the - side.

Two side notes: 1) I needed a resister for both high and low beam circuits. Only having on one circuit caused idiot light to stay on on dash. 2) the headlight only has a single - lead so the black wires from the resistors are both plugged into same wire.

My main objective in doing this was to get the idiot lights to not illuminate on the dash while still retaining their original function (ie to tell you when u have a burnt out bulb). My testing/validation of this was to use a clip on multimeter and test amps draw with incandescent bulb, then do same measurement with LEDs installed. As i recall, it was a drop of about 3.6A on each circuit (high/low beam). That comes out to be about 43w of load that i needed to simulate with resistors. I re-tested with after installing the load simulators and got (near) expected results. Originally, i installed the 50w load simulators. These were close to the 43w of load that i needed to simulate. These were made of metal and had a proper heat sink. My thinking was that i would mount these outside of the headlight case thus air flow would keep them cool. In the end i went back to the 10w load simulators. Three reasons: 1) The 50w's got HOT, HOT, HOT. 2) The 10w ones provided enough load to take care of the idiot lights and 3) it just seemed silly to force my R/R to work hard for that extra 80w (50w-10w times 2) that is just being wasted by by the load simulators.

Suzukian Is my understanding correct? Do i have them wired up correct? If my only objective is to make the idiot light perform correctly, is there an easier way to accomplish this?

Thanks for your reply and very best regards,

Darrell

1983 GS1100ED (red) / 1983 GS1100ED (blue)

- Likes 1

Comment

-

I think so, by mounting them in parallel, the parallel resistor is dumping a lot of current thought heat by a voltage drop, the lowering the current. This leaves enough for the headlight. If the headlight goes out, you don't have to worry about frying the system because nothing is dropping the voltage. It's the way I'd do it. If you wanted to mount extra lights, or a really loud obnoxious Horn, like the set of FIAMM's I have on my GS750ES, you could mount them again in parallel with the same circuit, the current will follow the path of least resistance, and the electricity would be used up, rather than just being turned into hit. Anything I mounted off of there I would mount with a relay and/or fuse.

Comment

.png)

Comment