SMs bike would leave the dash panel and other systems hot when the key was turned off. So he checked the fuses and found the main (top) fuse had actually melted the solder on one end and was cockeyed, pushing the main fuse contact down onto the one below. Thus, the phantom dash lights.

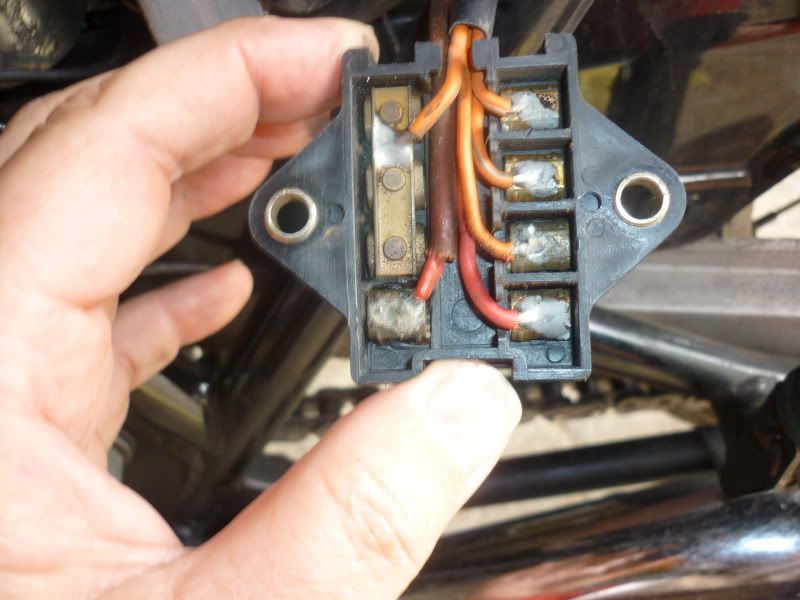

Further investigation showed the fuse panel itself had heated up enough to melt the solder on the main power wire (the big red one from the battery). Note that it was just sitting in the hole.

He borrowed a fuse box from Bruce and made it home

My bike lost 2 cylinders while I was passing a log truck on a mountain road. I limped into town and pulled the fuse box open to find the main fuse had slid forward and was barely contacting the right hand clip. I squeezed the clips, reset the fuse and put some tape around the fuses for safety and made it home.

I had recently swapped my original fuse box for a spare one after my bike went dead passing a semi on a mountain highway (bad trend here)

I checked my spare and found the main connector (upper left) to be loose

I finished pulling the box and found it had been resoldered at some point

I noticed the plug had overheated at some point also

I went back to my original one, which does not show any overheating damage. I cleaned the inside of the clips while I was in there.

So, since these bikes have a tendancy to "cook" the electric components, pulling two screws and checking the back of your fuse panel is worth your time.

.png)

Comment