This is my first post here on The GS Resources and I own a 1983 GS750ES which I received from a friend from church who was the original owner. It was in pretty good mechanical condition when I received it but it was down 2 times I think.

Overall the bike ran after sitting for 5 years after some routine maintenance and I have been riding it for 2 years and nothing major happened other than my stator and rectifier blew while I was about an hour and a half from my house.

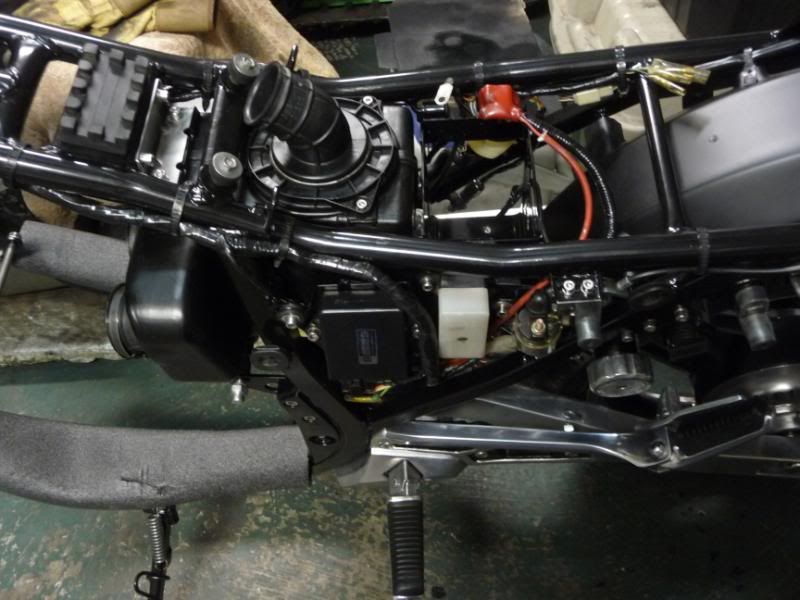

I recently decided that a partial rebuild is in order for the bike, which I see as simply cleaning EVERYTHING, replacing old tubes and hoses, and fixing the general broken stuff on the bike.

I believe that the electrical system is not at 100% and so I want to clean all of the connectors and wires and test all of the different components that may be faulty and clear up the whole issue of charging in one fell swoop.

Now to the question that I have. After doing a lot of thinking I want to clean up everything under the seat. Part of that would include potentially running the wires from the wiring harness through the frame by drilling a hole at various points in the frame to allow for the wires to get to their different destinations. I am wondering if this will weaken the integrity of the frame and make the motorcycle dangerous to ride? Is there another way to hide wires or make them impervious to the weather?

Let me know and thank you so much for reading this!

Geoff Weakley

Comment