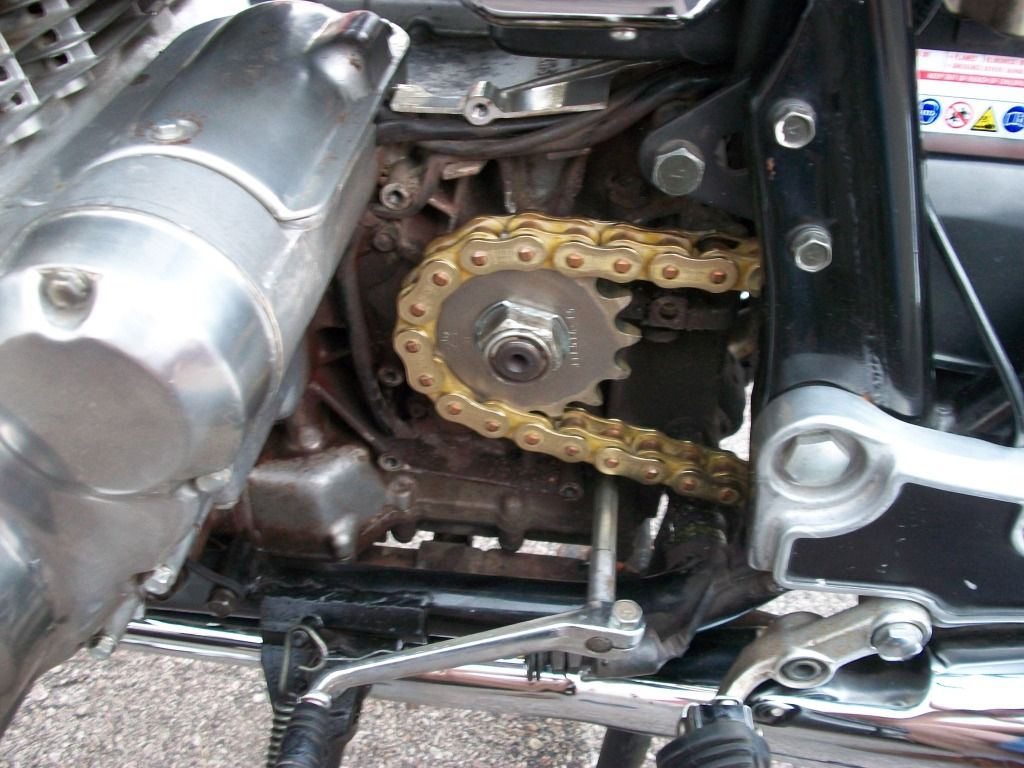

I replaced sprockets and chain on my '82 750E today.

I replaced sprockets and chain on my '82 750E today.The new JT brand front did not have the flared center offset as the older (but beautiful very well heat-treated) Sunstar did.

It was late in the afternoon and I needed a solution. The local machine shop cut me a "shim" out of steel round stock after I had carefully measured my requirement.

I have included a picture showing one of the shims which was cut a little narrow. The one I used was just right.

My question: is this steel stock "shim" adequate to NOT fracture with torque applied to the nut? I.E., will this shim fracture over time? Should I have spent more time locating steel washers of accumulated proper thickness?

After I was done putting this all together and torquing the output shaft nut to about 100 lbs (good guess as my torque wrench was elsewhere and I was having a difficult time doing the balancing act to accomplish the task of holding the bike and applying pressure to the rear brake) I got to thinking about the potential for disaster.

This JT brand sprocket was supposed to be identical to oem.

And before you ask, I do like 630 RK SO chain. Have never had a complaint running this stuff on my GPz. Never needs tightening. I part with those of you who have to have lighter 530.

.png)

Comment