Announcement

Collapse

No announcement yet.

Fork seal leaks 82 gs550lz

Collapse

X

-

Fork seal leaks 82 gs550lz

So I am in the middle of replacing the for seals on my 82gs550lz. The right fork is the one that had a noticeable leak and I am replacing both seals. In the attached picture the leaky fork has oil under the seal and the non leaky fork does not, is this normal? Do I need to replace any secondary seals below the main seal?

Tags: None

Tags: None

-

Could be the one without the oil in the pic leaked it all out a long time ago. There's just the one seal, take it all apart, clean everything, there is a lot you can do to improve the action of the forks. It also looks like there may be some pitting on the fork tubes, if this is true it will start the new seals leaking all over again very soon.

-

snojobz

snojobz

Next questions. The service manual specifies a special tool to get the rest of the fork apart, are there any standard tools I can use?

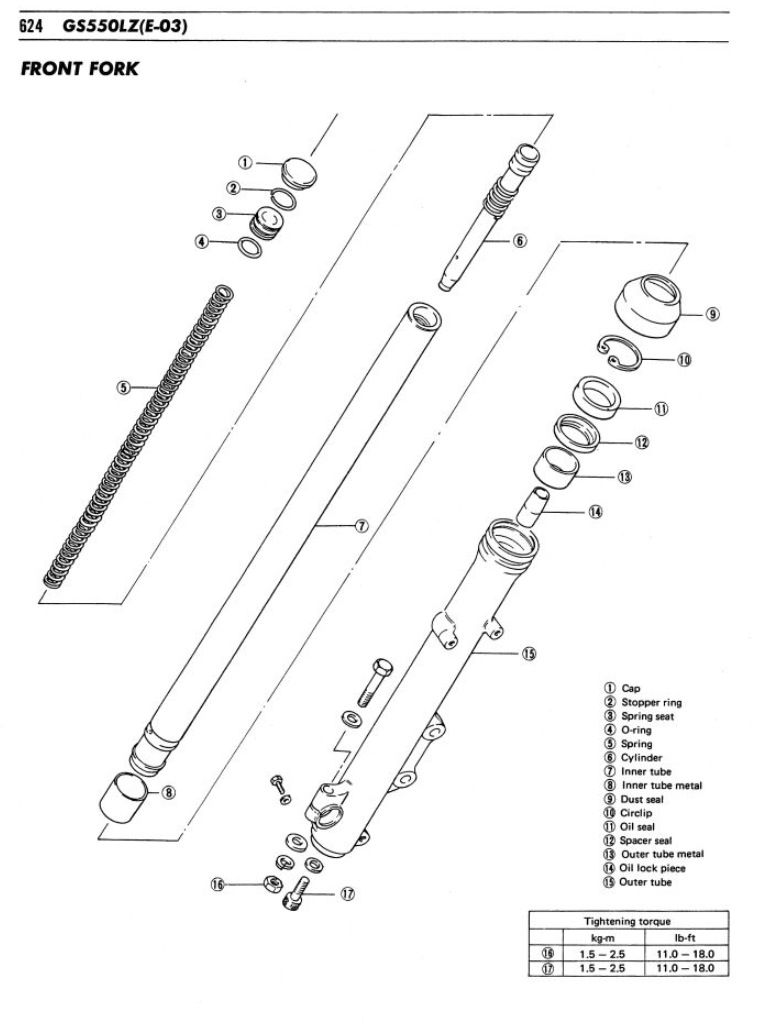

The manual also call for replacing the inner and outter metals "anti-friction materials" when dissassembling, parts 8 & 13 on the diagram, is this really necessary?

Also, I think the fork seals were in upside down, bikecliff says that the open edge with the coil spring band should face the bottom of the fork, but mine were facing up... That is backwards right?

If there is a little bit of pitting on the tubes, can I polish them with something? Or do they need to be replated?

Thanks!

Comment

-

An air impact on the allen head bolt will take it apart, best to do it before the spring tension is removed. Or try a broomstick pushed down onto the top of the damper rod. Another option is a sprk plug socket upside own on a bunch of extensions, or some folks make up a tool out of allthread and nuts.

If those inner and outter metals are shot, replace them. If not, don't.

Your seals were upside down. That by itself is enough to make them leak.

The pitting on the tubes can be polished, but how bad are they? Need a better pic.

Comment

-

If you don't have an air impact, use a hex head socket and adapter in your corded drill. Just leave the fork put together so it provides resistance to prevent things turning.

To add on to this question, how would he get those metal sleeves out?Cowboy Up or Quit. - Run Free Lou and Rest in Peace

1981 GS550T - My First

1981 GS550L - My Eldest Daughter's - Now Sold

2007 GSF1250SA Bandit - My touring bike

Sit tall in the saddle Hold your head up high

Keep your eyes fixed where the trail meets the sky and live like you ain't afraid to die

and don't be scared, just enjoy your ride - Chris Ledoux, "The Ride"

Comment

-

snojobz

snojobz

I have an impact gun, but no 6mm bit. My t-handle wrench can't get enough torque on the bolt.

The tubes only have a little bit of pitting and it's only where they bolt to the head. The sliding surfaces are clean.

I am inclined to just put the new seals in and fill them back up, any reason not to?

My next problem is fuel delivery. I found 5qts of oil/gas in the bottom end. From bike cliff notes I'm looking at a new needle valve on cyl2 and a new petcock. I already replaced all the needle valve orings last week when I cleaned the carbs. I have an overflow issue on cyl 2. And my freshly cleaned carbs look dirty already... I put 1 mile on the bike and have maybe 10 min of garage run time on the bike since the carb clean.

Comment

.png)

Comment