Announcement

Collapse

No announcement yet.

Sheared bolts in GS1000 cylinder head

Collapse

X

-

Your technique works great, unless it's a blind hole...Knowing an EZ outs limits is the key and like Brian mentions about what he learned on a machinist forum, they shouldn't be used for seized fasteners, just broken ones. I've learned that the hard way and after that I tried tricks like where you weld a washer on and then weld a bolt onto it and turn that out. With this method, you get blowerbike's recommendation too.Originally posted by Fjbj40 View Post----------------------------------------------------------------

2014 BMW F800GSA | 1981 GS850GX | 1982 GS750T (now the son-in-laws) | 1983 GS750ES | 1983 Honda V45 Magna (needs some love) | 1980 Yamaha GT80 and LB80 "Chappy" | 1973 and 1975 Honda XL250 projects

-

It works just fine if it is a blind hole. You just have to make sure you only drill through the bolt and not into the part and that is a straight forward procedure.Originally posted by mikerophone View PostYour technique works great, unless it's a blind hole...Knowing an EZ outs limits is the key and like Brian mentions about what he learned on a machinist forum, they shouldn't be used for seized fasteners, just broken ones. I've learned that the hard way and after that I tried tricks like where you weld a washer on and then weld a bolt onto it and turn that out. With this method, you get blowerbike's recommendation too.

There are many different techniques for removing broken fasteners. Some are usually a bigger challenge, the trick is taking your time and thinking it through. Being in a hurry can often cause more grief. Slow down, access and evaluate the path for rectification will usually ensure a positive result. Asking questions if you have never done it is the first step, as the OP is doing.1978 Gs1085 compliments of Popy Yosh, Bandit 1200 wheels and front end, VM33 Smoothbores, Yosh exhaust, braced frame, ported polished head :cool:

1983 Gs1100ESD, rebuild finished! Body paintwork happening winter 2017:D

I would rather trust my bike to a technician that reads the service manual than some backyardigan that THINKS HE KNOWS how to fix things.

Comment

-

I should have worded my post better, it was not my intention to offend and hopefully I didn't. I've never attempted to drill through a broken bolt in a blind hole as I'm worried that I won't feel the bit break through. What's your method/tip there? Pretty easy to feel it change based on the metal type differences?Originally posted by Fjbj40 View PostIt works just fine if it is a blind hole. You just have to make sure you only drill through the bolt and not into the part and that is a straight forward procedure.

1978, any luck with your 4 bolts? If there are still threads adequately exposed, heat, PB Blaster, more heat, tap tap tap with hammer, maybe wait a day, apply more heat/more PB , tap tap and then use vise grips or notch the bolt with a dremel and tackle that way. Personally I have switched to a 50/50 mix of good acetone and ATF.over PB Blaster. It works great.----------------------------------------------------------------

2014 BMW F800GSA | 1981 GS850GX | 1982 GS750T (now the son-in-laws) | 1983 GS750ES | 1983 Honda V45 Magna (needs some love) | 1980 Yamaha GT80 and LB80 "Chappy" | 1973 and 1975 Honda XL250 projects

Comment

-

Often there is another hole that has not got a broken fastener in it so I measure the hole depth and use it as a reference.Originally posted by mikerophone View PostI should have worded my post better, it was not my intention to offend and hopefully I didn't. I've never attempted to drill through a broken bolt in a blind hole as I'm worried that I won't feel the bit break through. What's your method/tip there? Pretty easy to feel it change based on the metal type differences?

1978, any luck with your 4 bolts? If there are still threads adequately exposed, heat, PB Blaster, more heat, tap tap tap with hammer, maybe wait a day, apply more heat/more PB , tap tap and then use vise grips or notch the bolt with a dremel and tackle that way. Personally I have switched to a 50/50 mix of good acetone and ATF.over PB Blaster. It works great.

If not then a slow feed with multiple removal and inspections and a "feel" for the "break-through" is required. Often there is a void in a blind hole (bolt usually does not bottom out) so you can feel the break through. Once again this comes from experience, something I gained from living on the corrosive East Coast of Canada :-).

No offense taken, it's all good. Hopefully someone learns from our ramblings Last edited by Fjbj40; 01-01-2015, 05:16 PM.1978 Gs1085 compliments of Popy Yosh, Bandit 1200 wheels and front end, VM33 Smoothbores, Yosh exhaust, braced frame, ported polished head :cool:

Last edited by Fjbj40; 01-01-2015, 05:16 PM.1978 Gs1085 compliments of Popy Yosh, Bandit 1200 wheels and front end, VM33 Smoothbores, Yosh exhaust, braced frame, ported polished head :cool:

1983 Gs1100ESD, rebuild finished! Body paintwork happening winter 2017:D

I would rather trust my bike to a technician that reads the service manual than some backyardigan that THINKS HE KNOWS how to fix things.

Comment

-

I'm learning, hopefully the OP comes back at some point and does as well.Originally posted by Fjbj40 View PostOften there is another hole that has not got a broken fastener in it so I measure the hole depth and use it as a reference.

If not then a slow feed with multiple removal and inspections and a "feel" for the "break-through" is required. Often there is a void in a blind hole (bolt usually does not bottom out) so you can feel the break through. Once again this comes from experience, something I gained from living on the corrosive East Coast of Canada :-).

No offense taken, it's all good. Hopefully someone learns from our ramblings

I'm glad there was no offense taken...That's a good point, measure another hole and use the electrical tape over the bit at the proper depth trick. Otherwise feel for the breakthrough. I'm sure I'll get the chance to try it at some point.

Is your user name a mixture of your name and a Toyota Landcruiser by chance?----------------------------------------------------------------

2014 BMW F800GSA | 1981 GS850GX | 1982 GS750T (now the son-in-laws) | 1983 GS750ES | 1983 Honda V45 Magna (needs some love) | 1980 Yamaha GT80 and LB80 "Chappy" | 1973 and 1975 Honda XL250 projects

Comment

-

My username, yes, it is/was my other hobby. Land Cruiser restorations and modifications. FJ40 to BJ40 conversions, played with those for about 17 years, came back to bikes a few years ago. Did 2 GS1000's prior to my current 1000.Originally posted by mikerophone View PostI'm learning, hopefully the OP comes back at some point and does as well.

I'm glad there was no offense taken...That's a good point, measure another hole and use the electrical tape over the bit at the proper depth trick. Otherwise feel for the breakthrough. I'm sure I'll get the chance to try it at some point.

Is your user name a mixture of your name and a Toyota Landcruiser by chance?

You can see my last 40 in this post http://www.thegsresources.com/_forum...-gs1000e/page7

cheers,

Daryl1978 Gs1085 compliments of Popy Yosh, Bandit 1200 wheels and front end, VM33 Smoothbores, Yosh exhaust, braced frame, ported polished head :cool:

1983 Gs1100ESD, rebuild finished! Body paintwork happening winter 2017:D

I would rather trust my bike to a technician that reads the service manual than some backyardigan that THINKS HE KNOWS how to fix things.

Comment

-

Nice! I get to replace the 3.0 in my 95 4runner this spring, it finally blew the head gasket...wish there was a diesel version available in the states. I think I will go with the 3.4l conversion if I can find one for ~$1500.----------------------------------------------------------------

2014 BMW F800GSA | 1981 GS850GX | 1982 GS750T (now the son-in-laws) | 1983 GS750ES | 1983 Honda V45 Magna (needs some love) | 1980 Yamaha GT80 and LB80 "Chappy" | 1973 and 1975 Honda XL250 projects

Comment

-

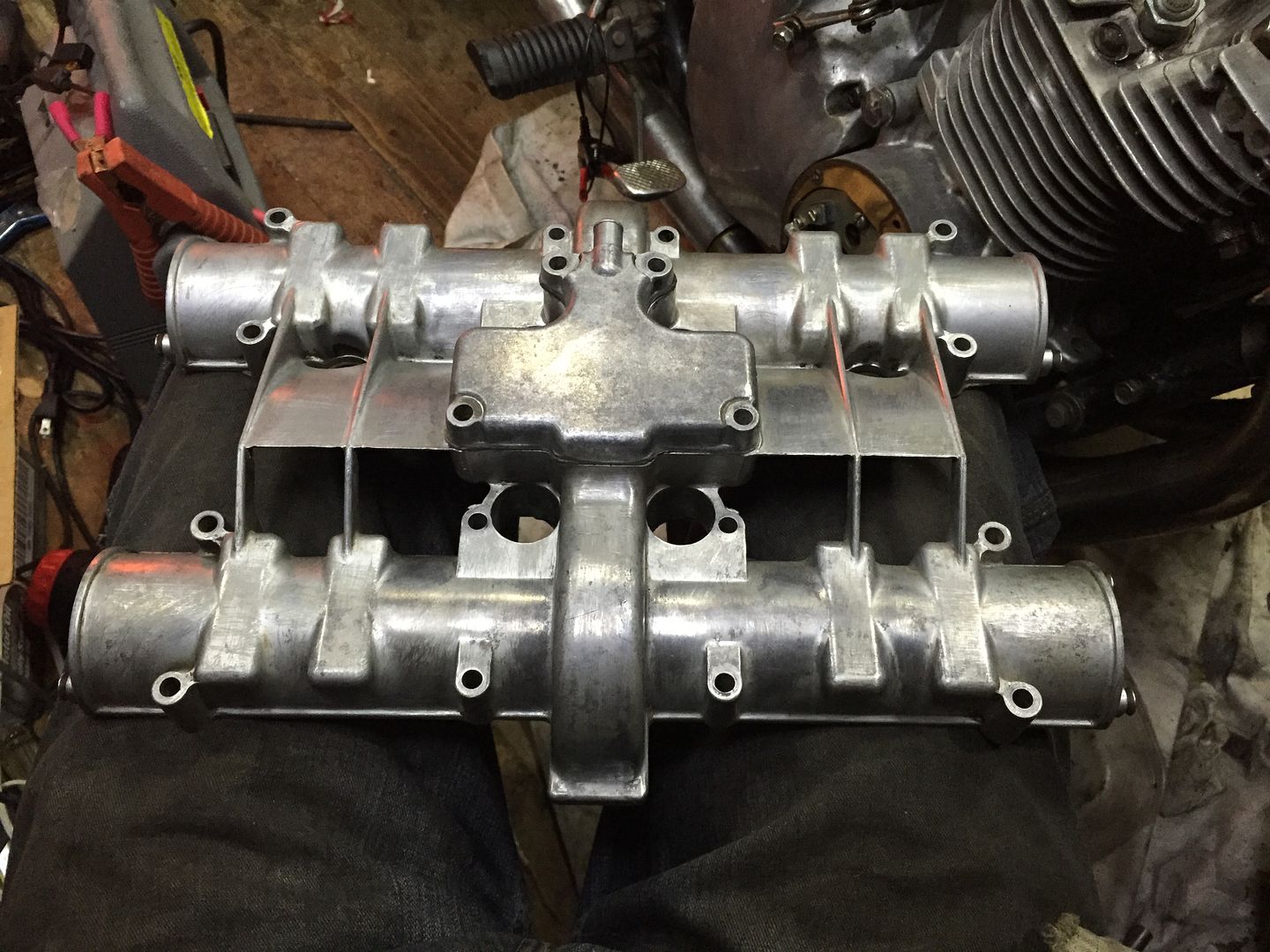

Polished breather covers are pointless.Originally posted by mikerophone View PostMight still polish it but at least I can try to extract the bolt remains OFF the bike ...

Pretty, but pointless.

.sigpic

mine: 2000 Honda GoldWing GL1500SE and 1980 GS850G'K' "Junior"

hers: 1982 GS850GL - "Angel" and 1969 Suzuki T250 Scrambler

#1 son: 1986 Yamaha Venture Royale 1300 and 1982 GS650GL "Rat Bagger"

#2 son: 1980 GS1000G

Family Portrait

Siblings and Spouses

Mom's first ride

Want a copy of my valve adjust spreadsheet for your 2-valve per cylinder engine? Send me an e-mail request (not a PM)

(Click on my username in the upper-left corner for e-mail info.)

Comment

-

Breather cover, yes, but the valve cover itself - I have a theory that they stay cooler, and are easier to clean, being less porous when polished.Originally posted by Steve View PostPolished breather covers are pointless.

Pretty, but pointless.

I might be wrong, and it's not the hottest part of the engine, but the paint on the cover likely holds heat in, and the paint has microscopic holes that oil, mixed with dirt and grease will cling to, whereas a pointless, but pretty polished cover, will let more heat out and stay cleaner at the same time, and doubles as a built in coil connection verifier, aka a mirror.

polished cover, will let more heat out and stay cleaner at the same time, and doubles as a built in coil connection verifier, aka a mirror.  ----------------------------------------------------------------

----------------------------------------------------------------

2014 BMW F800GSA | 1981 GS850GX | 1982 GS750T (now the son-in-laws) | 1983 GS750ES | 1983 Honda V45 Magna (needs some love) | 1980 Yamaha GT80 and LB80 "Chappy" | 1973 and 1975 Honda XL250 projects

Comment

-

90% of the holes I drill in steel, I can hear the tone of the motor change as it approaches breakthrough and the drill load lessens. Right after that is when to ease off slightly and be ready. Of course, some drills and bits don't give this warning, so they can catch you out.Originally posted by mikerophone View PostI should have worded my post better, it was not my intention to offend and hopefully I didn't. I've never attempted to drill through a broken bolt in a blind hole as I'm worried that I won't feel the bit break through. What's your method/tip there? Pretty easy to feel it change based on the metal type differences?---- Dave

Only a dog knows why a motorcyclist sticks his head out of a car window

Comment

-

1978

1978

Hah, honestly I haven't tried yet. Just messing around with the carbs right now because I'm a bit nervous and just waiting for all the responses to roll in on this thread before I attempt. I've got a set of left hand bits and the EZ outs as well now.Originally posted by mikerophone View Post1978, any luck with your 4 bolts? If there are still threads adequately exposed, heat, PB Blaster, more heat, tap tap tap with hammer, maybe wait a day, apply more heat/more PB , tap tap and then use vise grips or notch the bolt with a dremel and tackle that way. Personally I have switched to a 50/50 mix of good acetone and ATF.over PB Blaster. It works great.

Comment

-

Left handed bits all the way. EZ outs are too risky. Just my $.02 but I've had too many break on me. Whereas if you drill through, starting small in the center (use a punch if you can to get perfectly centered) and heating, lubing and going up a bit size each time, eventually it may just turn out when you're drilling.----------------------------------------------------------------

2014 BMW F800GSA | 1981 GS850GX | 1982 GS750T (now the son-in-laws) | 1983 GS750ES | 1983 Honda V45 Magna (needs some love) | 1980 Yamaha GT80 and LB80 "Chappy" | 1973 and 1975 Honda XL250 projects

Comment

-

cl4yd0h

cl4yd0h

I laughed so hard at this... Thank you..Originally posted by bwringer View PostWhatever you do, do NOT try EZ-outs. They do NOT work on stuck bolts. They WILL break, and then you're really floating down fecal creek with no means of propulsion

Ez outs are not very good at removing bolts but work surprisingly well for a bout of swearing and feeling sorry for yourself..

Comment

-

Me too!

Stripped bolts that you can't cut a notch or get vise grips on yes, frozen bolts that result in sheared heads...nope.----------------------------------------------------------------

2014 BMW F800GSA | 1981 GS850GX | 1982 GS750T (now the son-in-laws) | 1983 GS750ES | 1983 Honda V45 Magna (needs some love) | 1980 Yamaha GT80 and LB80 "Chappy" | 1973 and 1975 Honda XL250 projects

Comment

.png)

Comment