Last year I lost the rubber trim off the left side of the GK fairing. Lost it on a ride across state, at night. Did not notice till the next day. If the trip had been 15 or 30 miles, I would have gone back and retraced the route looking for it, even if it took 4 hours. I suspected that it was going to be hard to replace.

I knew those rubber trim pieces had spring metal in them, and was not going to find some generic stuff, would have to be specifically that left side trim piece for a GK fairing since they were formed to shape (or so I thought at the time).

I definatly knew it had spring steel in it, since Had seen it on ones that had road rash damage, like this one on extra fairing I have in basement.

And I did have one of one come loose once before, and I did find that it was quite stiff, and formed to shape.

Mine was near perfect. Had the slightest skuff from a tip over.

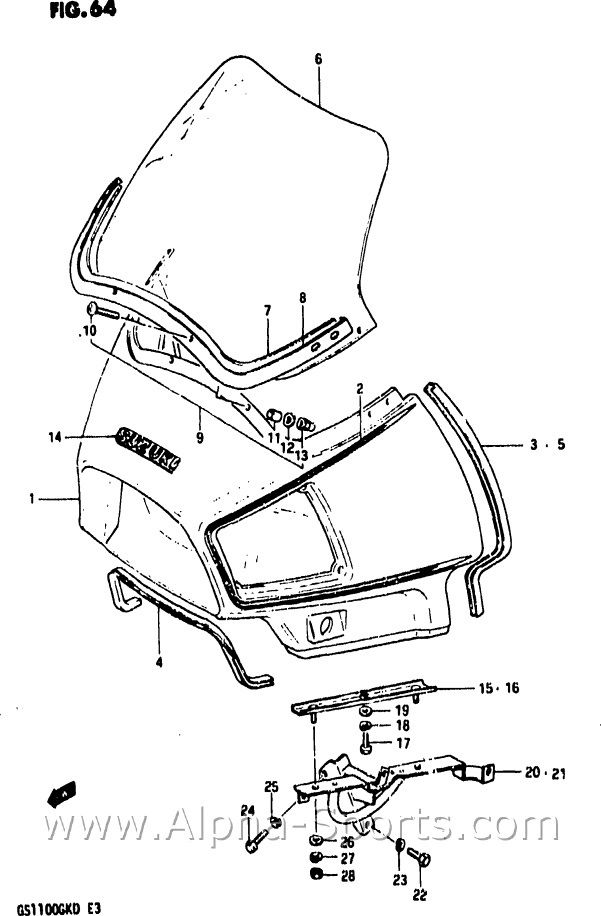

First step, get part numbers.

Alpha Sport good for that, because their microfiche / stock numbers use the OEM part numbers.

First thing: on the microfisch, that is not a fairing, that is a "cowling". And those trim pieces are "mouldings".

tag 3- OEM part number 94417-49400 moulding RH

4- 94419-49400 moulding Lower

5- 94427-4940 moulding LH

All of which no longer available, no surprise there.

Did some searchs .... did get some hits, but nothing available. And what I did find, yep, sure looked like I specifically needed the LeftHand one, since they are shaped/moulded/formed to the specific contour of that side.

Set up a couple different e-bay searches, some on those part numbers and some more like GK fairing trim or moulding. Did get emails from time to time, but not what I was looking for.

I did stop at a industrial rubber supply company, with a little sketch I had made. Nope nothing like that, well, some things like that but not in the dimensions.

Months went by. THen got an ebay email about a NOS part, but was the RH part not the LH hand part I needed,

and was asking way too much for it. B

ut I looked anyway.

And it had this picture.

What....? THat is not formed at all. Doesn't look long enough either. Part number is just hand written, not in original packaging. Maybe, I thought, that is really the lower moulding, but it is not formed to that shape either.

I did chat with seller, who gave me the length, and told me it was stiff, but would bend easy in one direction to curl it up but not bend easy to bend it sideways. Hum.... so yah, is long enough to be the side trim (not the lower).

But, if it is not formed/shaped, what about that piece made it the RH, not the LH I needed....?

Hum, so what is different between the RH and the LH piece....?

I looked at the ones on the beatup extra fairing I have, and I looked at the remaining trim piece I had. THe inside edge is different than the outside edge, okay, but if took the trim off one side and turned it around to put on the other side... what would be different (other than the general contour)....? Only thing I could find was on the top inside edge, the inside edge was cut at about a 45 degree angle so it fit better up by the windshield. (and that cut angle isn't shown in the microcrofishe drawing of the part).

And I thought about it some more, and realized that if put the RH moulding on the left side, it would just be that the upper end with that angled cut would be on the bottom not the top, and then the top would not have that angle cut end, but heck, I could cut it somehow if needed.

So I placed a "make an offer" at what I thought was just a little over a reasonable price.

No response.

A couple weeks later, I made an offer about halfway between reasonable and his too much. THat time he came back with a price that was almost too much but included shipping (amazing how effective an offer free shipping is, even if you know its only 5 or 6 bucks).

And , dern it, was not going to find anything better. And so, I overcame my cheapo nature I got it.

Was surprisingly flexible to curl it in on itself, but real stiff to bend sideways (hard to describe).

Seemed a bit longer than needed to be, so, yah, that one inside edge did need to be cut for it to fit inplace. Tried to cut with a big pair of tin snips, but ended up using a disc grinder.

Took a little effort to push into place, and some wiggle working to get it to form to the contours. ...

but ahhh....

mo' better, mo' better now.

.png)

Comment