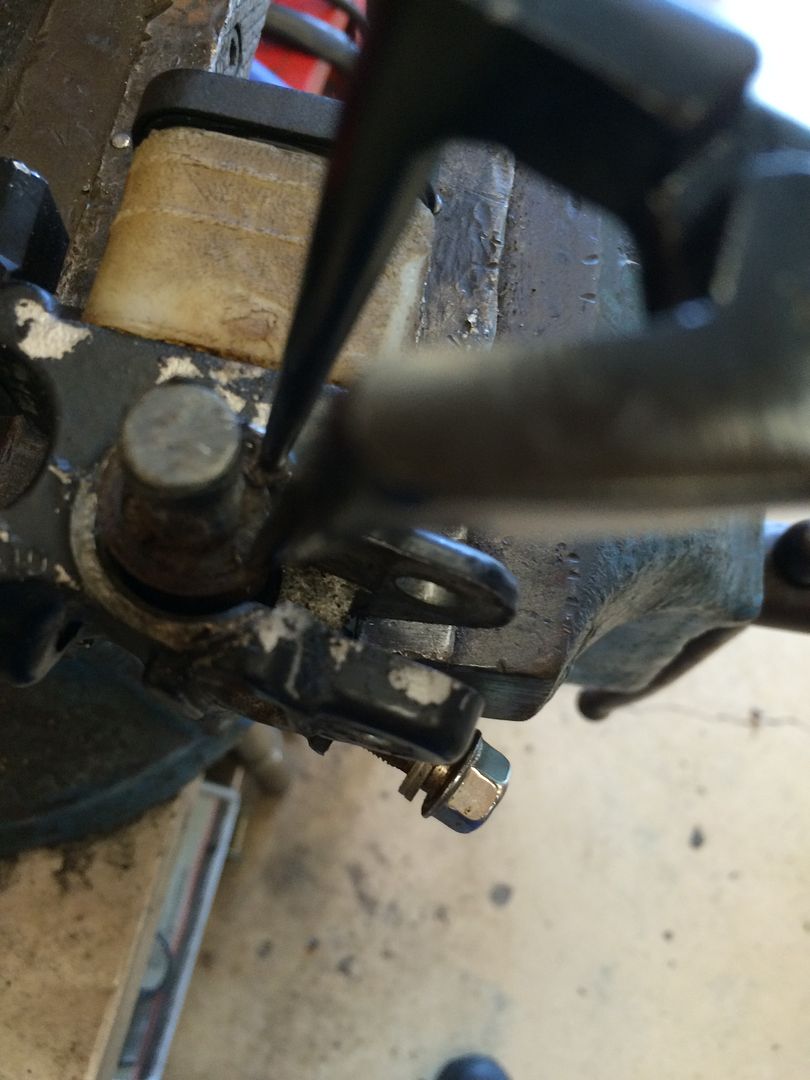

Brake lever removed and lightly held in a vice. Remember you don't want to break it and it's aluminum so fragile. My new clip ring pliers to get the circlip out. There was a lot of crud covering this and the rubber dust boot just fell apart exposing the Circlip. Cleaned up a little and time to go after the clip.

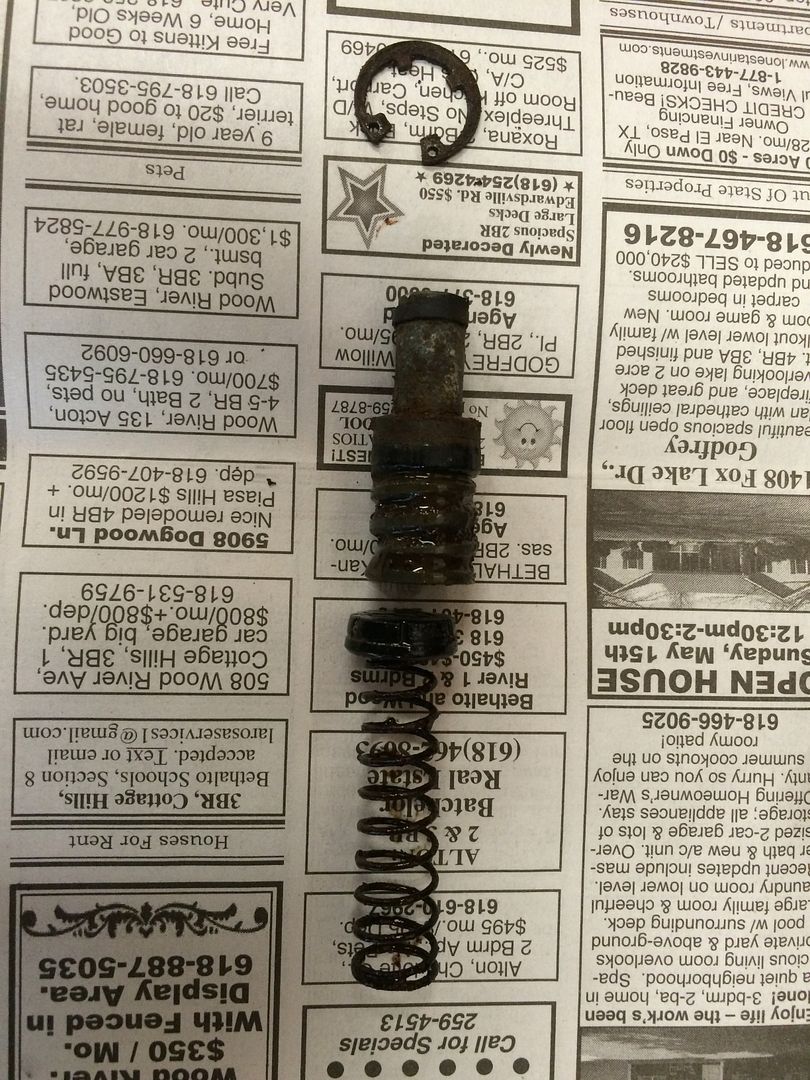

Once the clip was out it was easy to do with these pliers by the way, the piston was easy to remove. Not so easy all the time but I got lucky. Careful as this whole thing is spring loaded. All of the parts layed out in the order in which they are assembled. VERY important to keep this orientation! Note both rubber "cups" face the same direction.

Inside the bore and it's pretty nasty in there. Rusty and grimy looking stuff.

Pry off the plastic reservoir and look at the rusty mess underneath. That rusty spot, to the right of the main hole, is the spooge or return hole. Dig out the crud with a screwdriver tip or anything really to get that stuff out of there. The spooge hole is in the bottom of the cone shaped hole. It's tiny. I use a precision drill #80 and my pin vise to clean the hole. TIP: soak that hole with some PB Blaster for a couple of minutes first to soften up the crud.

With my flashlight shining into the bore you can see now that the spooge hole is open and how tiny it really is:

Put it back together using brake fluid ONLY and re-insert the clip. The thing is spring loaded so you have to hold the piston assembly down while inserting the clip.

That's really all there is to it. Pretty simple huh?

Probably should have included the link to the pliers. I know $25 is a lot of money but what you didn't see was the frustrating couple of hours I spent trying to dig that circlip out of there. This literally took me 1 minute to remove the clip.

Also before you flame me on how dirty the MC appeared after re-assembly, you have to realize that I am never going to put this thing into service and so the bare minimum of cleaning was done just so I could make this thread.

Comment