So now, the task is how are you gonna get enough torque and be able to twist the head back in line and check for plumb?? Well I didnt take pics of the first stage of how i stabilized the bike and made my rig so I will try and describe that part as well as I can.

How to get the bike locked down so you can apply twist to the head.....simple. You set the bike against the rear wheel of a Ford 8N tractor and chain the frame right behind the head to the rear axle. And then you use a come along around the swing arm and ratchet the bike tight up to the wheel. Bike solidly locked to the rear wheel I needed to begin to twist the head back..but with what???

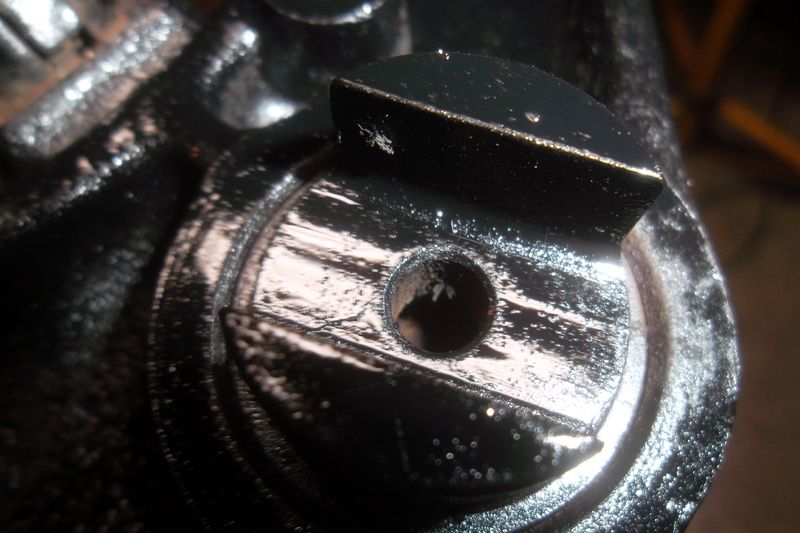

To twist the head I drove the top bearing race of the head and stuck a bent fork down the hole. next went a pair of vice grips on the tube about a foot above the top of the steering head. This was a stop for the chain.

Next was to wrap a chain around the fork sticking up, set an 8 foot 4x4 landscaping timber ( one with the rounded edges) against the bottom edge of the head. Now wrap the rest of the chain around the 4x4 and get at twisting the head. Now I dont know exactly how much pressure it takes to snap one of those timbers but I broke this one twice....but i got enough twist to get it darn close by eyeballing it.

Posb two will be on making a tool to read the center line of the lower triple to check for left to right plumb.

.png)

Comment