Announcement

Collapse

No announcement yet.

GS1100 Swingarm Alloy Grade

Collapse

X

-

GS1100 Swingarm Alloy Grade

Yes i know its alloy but what grade is it? Thinkn mite be anodized 6000 series grade but like to be sure. Anyone? I know it maybe a tough question but prefer no guessing, thanks in advanceTags: None

-

Looked at this myself some time back. Best guess is 7003,7004 or 7005 - which are Japanese alloys for extrusions. You won't match these outside Japan.Originally posted by sharpy View PostYes i know its alloy but what grade is it? Thinkn mite be anodized 6000 series grade but like to be sure. Anyone? I know it maybe a tough question but prefer no guessing, thanks in advance

Bradley in his book "The racing Motorcycle" recommends 5356 as probably the best choice of weld filler.

I've braced one of these arms. The good friend who welded it used the nearest NZ market equivalent to 5356. Welded well and no problems since. No post weld heat treatment either.

-

Forum LongTimerGSResource Superstar

Past Site Supporter

Super Site Supporter- Mar 2006

- 35865

- Torrance, CA

Typically, after aluminum is welded it needs to be age hardened in an oven because welding heat anneals the metal. When the first GSXR 750 came out there was mention of an aluminum alloy being used for the chassis that age hardened on it's own over the course of a few months while the bike was in transit. I'm not sure if the 1100 swingarm is similar but it wouldn't surprise me.Ed

To measure is to know.

Mikuni O-ring Kits For Sale...https://www.thegsresources.com/_foru...ts#post1703182

Top Newbie Mistakes thread...http://www.thegsresources.com/_forum...d.php?t=171846

Carb rebuild tutorial...https://gsarchive.bwringer.com/mtsac...d_Tutorial.pdf

KZ750E Rebuild Thread...http://www.thegsresources.com/_forum...0-Resurrection

Comment

-

Don't do it with these arms would be my advice. The 7000 series alloys the japanese seem to use are age hardening. Any further hardening risks embrittlement.Originally posted by Nessism View PostTypically, after aluminum is welded it needs to be age hardened in an oven because welding heat anneals the metal. When the first GSXR 750 came out there was mention of an aluminum alloy being used for the chassis that age hardened on it's own over the course of a few months while the bike was in transit. I'm not sure if the 1100 swingarm is similar but it wouldn't surprise me.

If you add bracing to the underside, youre welding into an inverted C section on the legs which shouldn't affect much - certainly mine didn't warp.

I made a point of welding the front torsion box into the central reinforcing gusset, not the sides.

I used 3mm sheet for the front box and 7/8in OD X 3mm wall tube for the sides.

As an aside, pretty sure I've seen Rob Phyllis quoted somewhere as saying that he and Hone never used the alloy arm, just the stock steel one, braced.

Sharpy will know who I'm talking about.

Comment

-

sharpy

sharpy

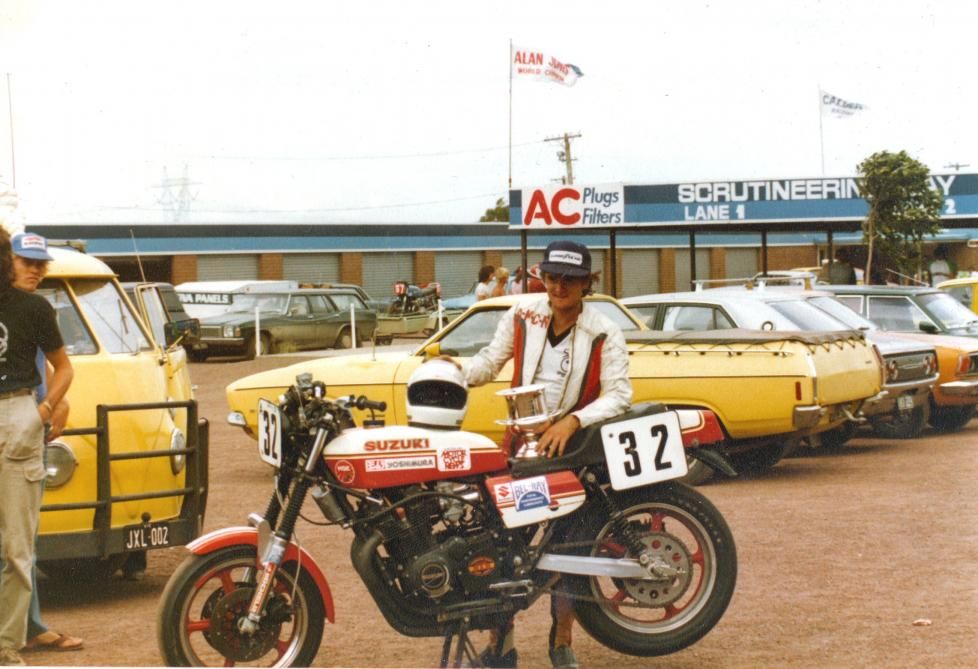

Yeah. his "stock" steel one was a McKintosh arm. Was on his Kat and even the alloy one was on his 1000ST. Hey Greg, reckon we/I should say Phillis would have kicked Cooleys butt any day of the week, or that starting trouble?Originally posted by GregT View Post

As an aside, pretty sure I've seen Rob Phyllis quoted somewhere as saying that he and Hone never used the alloy arm, just the stock steel one, braced.

Sharpy will know who I'm talking about.

Comment

-

Syph was at the recent Southern Classic meeting. I saw the interview on TV last week. "burn down all pit bunkers - the public want to see the bikes and people" was one of his milder edicts...He was in good form although not riding. He loved the open plan pits at Levels.

He started around the same time Cooley did but went on a lot longer - WSB wins were something Cooley never got to. Last year he was riding at that SC meeting - on my mate's Moriwaki Honda - which is the actual works bike he rode in Japan. Still bloody quick too.

Comment

-

sharpy

sharpy

If you ever get the chance have a sit on a Kat with the swan neck tingate handle bars/clip ons. Its the best riding position i ever had. very similar to the current GS500 twin believe it or not. We even had a term here called the robbie phillis wheelstand. Where one did a wheelie just under power. Now u know how old im getting lol

Comment

.png)

Comment