Announcement

Collapse

No announcement yet.

Stay arm

Collapse

X

-

Stay arm

I removed and painted my stay arm on reassembly does the split pins go through the castellated but or can the but be tightened and pins in front of but.I've bought new nuts and bolts and am drilling the hole myself.1983 GS 650 gl

1982 GS 850 gl

1980 GS 550L

1982 GS 650 G(KATANA)

Gsx 1400 daily rideTags: None

-

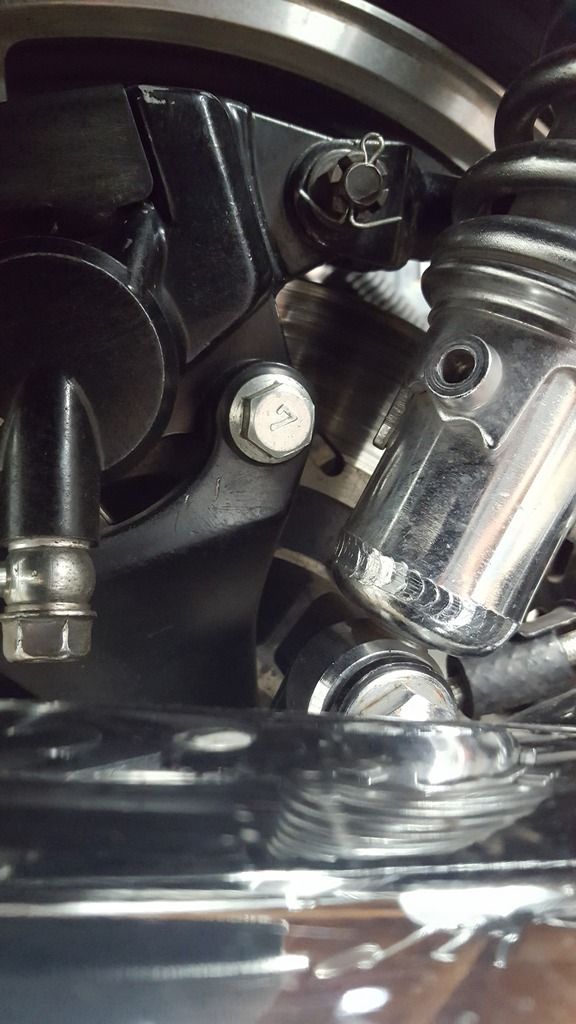

Here is pic of nut and bolt does split pin go through slit in nutIMG_20170625_222957.jpg1983 GS 650 gl

1982 GS 850 gl

1980 GS 550L

1982 GS 650 G(KATANA)

Gsx 1400 daily ride

Comment

-

No pics prior to repair? Boy, I've never done that!

Been thinking more about the purpose of the castellation (great term BTW, I would use something far less proper) and realized the depth of the notches give more leeway in assembly to achieve desired torque setting and split pin (cotter pin) insertion point. Whether or not the pin goes through the castellated part or butts against the other end of the nut may or may not matter as far as shearing off the pin [if in fact the nut loosens up enough from the movement in the stay arm] but would greatly increase the difficulty of assembling the part to spec, and having it stay there. I suppose you could torque to spec, then drill the hole in place but what a pain. That been said, will you torque the nut to spec, mark or measure where to drill, remove the bolt then drill and reassemble it? That's what I'd do FWIW.

Comment

-

There's a torque value for that?

I just snug it up, then see which way I will need to turn the least to get me to the next notch and turn the nut in that direction.

.sigpic

mine: 2000 Honda GoldWing GL1500SE and 1980 GS850G'K' "Junior"

hers: 1982 GS850GL - "Angel" and 1969 Suzuki T250 Scrambler

#1 son: 1986 Yamaha Venture Royale 1300 and 1982 GS650GL "Rat Bagger"

#2 son: 1980 GS1000G

Family Portrait

Siblings and Spouses

Mom's first ride

Want a copy of my valve adjust spreadsheet for your 2-valve per cylinder engine? Send me an e-mail request (not a PM)

(Click on my username in the upper-left corner for e-mail info.)

Comment

.png)

Comment