Announcement

Collapse

No announcement yet.

Carb tuning resource

Collapse

X

-

Mr_Shake

Mr_Shake

Carb tuning resource

Is there a site or page that has a step by step carb tuning tutorial for absolute noobs? I don't know the first thing about it, and would benefit from a basic walkthrough. I have found lots of tips and things, but they all elaborate on a basic understanding of carb tuning, and I don't have the slightest knowledge. Thanks!Tags: None

-

First of all, give us a clue what bike and/or carbs we are talking about.

I would hate to give you directions on tuning a Quadra-Jet.

.sigpic

mine: 2000 Honda GoldWing GL1500SE and 1980 GS850G'K' "Junior"

hers: 1982 GS850GL - "Angel" and 1969 Suzuki T250 Scrambler

#1 son: 1986 Yamaha Venture Royale 1300 and 1982 GS650GL "Rat Bagger"

#2 son: 1980 GS1000G

Family Portrait

Siblings and Spouses

Mom's first ride

Want a copy of my valve adjust spreadsheet for your 2-valve per cylinder engine? Send me an e-mail request (not a PM)

(Click on my username in the upper-left corner for e-mail info.)

-

Mr_Shake

Mr_Shake

Haha sorry guys. It is an '80 GS850G. They are Mikuni's, I assume they are CV. I traded a mountain bike for it from a friend. It fires up and runs and drives fine. It reeks of gas and exhaust backfires, and when it is cold, it pops from the carbs. When you pull the choke it smothers and kills it. I know I need to ckeck the valves, but I don't have all the parts/tools I need to do so yet. It has 45k miles, so I know it is needs some attention. The intake is pods, and the exhaust is some old 4-1 with hardly any baffle in it. It has two holes, one in header 3 and one in the pipe that I need to weld. Thanks!

Comment

-

ptm

ptm

Here are a few resources about Mikuni carbs. Nothing is a simple step by step, but a lot of general info. Some are specific to the earlier VM carbs, and it looks like from your previous posts that you have an '80 GS850, so you'll want to look for additional info on the later CV carbs..

The Mikuni Group manufactures superior products for a wide range of industries, including automotive, commercial vehicles, powersports, general purpose, household and safety, as well as export and sales of aerospace parts.

The Mikuni Group manufactures superior products for a wide range of industries, including automotive, commercial vehicles, powersports, general purpose, household and safety, as well as export and sales of aerospace parts.

The Mikuni Group manufactures superior products for a wide range of industries, including automotive, commercial vehicles, powersports, general purpose, household and safety, as well as export and sales of aerospace parts.

The Mikuni Group manufactures superior products for a wide range of industries, including automotive, commercial vehicles, powersports, general purpose, household and safety, as well as export and sales of aerospace parts.

http://www.sudco.com/ see the diagrams section

I also suggest searching the forum. There have been a lot of detailed explanations about how to deal with various issues. Whether you're trying to get a completely stock system to work, or deal with rejetting and adjustments to handle aftermarket air filters and exhaust.

Finally, if you have a specific issue you're trying to deal with, start a thread with as much info as possible about the bike, its behavior and what you've already tried. You'll be amazed at how much advice you get...

Comment

-

Ironriot

Ironriot

Hey I have a really good guide that I've gotten off of here... Or somewhere.... but anyways PM me and I'll send it over. Rather large file though

Comment

-

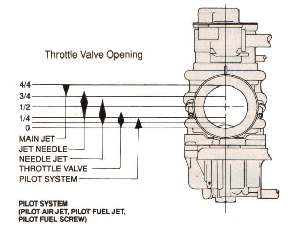

Follow steps in order....First, dial in:- 1. Top end (full throttle / 7.5k to redline -

Best Main Jet must be selected before starting step 2 (needle height)!- Select Best Main Jet

- To get the best, most even top end power (full throttle/after 7500 rpm), select the main jet that produces the hardest pull at high rpm.

- If the bike pulls harder at high rpm when cold and less hard when fully warmed up, the main jet is too large. Install a smaller main jet and retest until you find the main jet that pulls the hardest at high rpm when fully warmed up. This must be done first - before moving on to the other tuning ranges.

- If the bike doesn't pull well at high rpm when cold and gets only slightly better when fully warmed up, the main jet is too small.

- In order to properly tune the midrange and low rpm carburetion, THE MAIN JET MUST FIRST BE PROPERLY SELECTED after 10 to 15 minutes of hard use!

- Do not pay too much attention to the low-end richness when you are changing main jets - you still need to be using the main jets that produce the best power at high rpm. You will deal with the low-end / cruise later - after step 2.

- In order to properly tune the midrange and low rpm carburetion, THE MAIN JET MUST FIRST BE PROPERLY SELECTED after 10 to 15 minutes of hard use!

- If the bike doesn't pull well at high rpm when cold and gets only slightly better when fully warmed up, the main jet is too small.

- 2. Midrange (full throttle /5k-7k)

Step 1 (Best Main Jet) must be selected before starting step 2!- Select best needle clip position

- To get the best power at full throttle / 5k-7k rpm, adjust the needle height, after you have already selected the best main jet.

- If the engine pulls better or is smoother at full throttle/5k-7k in a full throttle roll-on starting at <3k when cool but soft and/or rough when at full operating temperature, it is too rich in the midrange and the needle should be lowered.

- If the engine pulls better when fully warmed up but still not great between 5k-7k, try raising the needle to richen 5k-7k.

- If the engine pulls equally well between 5k-7k when cooler as compared to fully warmed up, the needle height is probably properly set.

- Do not pay too much attention to the low-end richness when you are changing needle clip positions - you still need to be using the clip position that produces the best full throttle / 5k-7k power in conjunction with the main jets (Step 1) that produce the best power at high rpm. You will deal with the low-end / cruise next.

- 3. Low end (full throttle / 2k-3k)

Step 1 (Best Main Jet) and Step 2 (needle height) must be selected before starting step 3!- Float height (AKA fuel level & how to..)

- To get best low-end power, set float height (fuel level) so that the engine will accept full throttle, without missing or stumbling, in 2nd gear from 2.5k to 3k rpm at minimum.

- Float heights, unless otherwise specified in the installation guide, are measured from the "gasket surface" of the carb body to the highest part of the top of the float - with the float tang touching but not compressing the float valve spring.

- If the engine has a "wet" rhythmic, soggy area at full throttle / 3k-4k rpm, that gets worse as the engine heats up, lower the fuel level by resetting the float height 1mm greater (if the original was 13mm - go to 14mm). This will lower the fuel level, making full throttle / 2k-3k rpm leaner.

- If the engine is "dry" and flat between 2k to 3k rpm, raise the fuel level.

- Example: change float height from 15mm to 14mm to richen up that area.

- REMEMBER, since the main jet WILL affect low speed operation, the MAIN JET has to be within 1 or 2 sizes of correct before final float setting.

- Warning: If the engine is left with the fuel level too high,, the engine may foul plugs on the street and will be "soft" and boggy at part throttle operation. Adjust Floats to raise/ lower the Fuel Level.

- Base settings are usually given if a particular application has a history of fuel level criticalness. The Fuel level height in the float bowl affects full throttle/low rpm and, also, richness or leanness at cruise/low rpm.

- Reference: a bike that runs cleanly at small throttle openings when cold, but starts to show signs of richness as it heats up to full operating temperature, will usually be leaned out enough to be correct if the fuel level is LOWERED 1mm. Check out and RESET all: Suzuki (all), Yamaha (all) and Kawasaki (if low speed problems occur). Needless to say, FUEL LEVEL IS EXTREMELY IMPORTANT!!!

- Warning: If the engine is left with the fuel level too high,, the engine may foul plugs on the street and will be "soft" and boggy at part throttle operation. Adjust Floats to raise/ lower the Fuel Level.

- If there are low-end richness problems, even after lowering the fuel level much more than 1.5mm from our initial settings, check for needle wear and needle jet (part of the emulsion tube). See Worn Needle and Worn Needle Jet diagram. It is VERY common for the brass needle jets (in the top of the "emulsion tube") in 36mm, 38mm and 40mm Mikuni CV carbs to wear out in as little as 5,000 miles. Check them for "oblong" wear - the needle jet orifice starts out round! Factory Pro produces stock replacement needle jets / emulsion tubes for 36mm and 38mm Mikuni carbs. Click here

- REMEMBER, since the main jet WILL affect low speed operation, the MAIN JET has to be within 1 or 2 sizes of correct before final float setting.

- 4. Idle and low rpm cruise

- Fuel Screw setting (AKA mixture screws)

- There is usually a machined brass or aluminum cap over the fuel screws on all but newer Honda. It's about the diameter of a pencil. Cap removal details. Newer Honda carbs have no caps, but use a special "D" shaped driver, usually supplied in the carb recal kit. We do have them available separately, too. 800 869-0497 to order -

- Set for smoothest idle and 2nd gear, 4k rpm, steady state cruise operation. Set mixture screws at recommended settings, as a starting point. For smoothest idle, 2nd gear 4000 rpm steady state cruise , and 1/8 throttle high rpm operation. (pj tuning information)

- Pilot fuel mixture screw settings, float level (but, you've "fixed" the fuel level in Step 3 - which you have already done!) AND pilot jet size are the primary sources of mixture delivery during 4000 rpm steady state cruise operation.

- If lean surging is encountered, richen mixture screws (turn out) in 1/2 turn increments. Alternative pilot jets are supplied when normally required.

- Pilot fuel mixture screw settings, float level and pilot jet size also affect high-rpm, 0 to 1/8 throttle maneuvers. Too lean, will cause surging problems when the engine is operated at high rpm at small throttle openings! Opening the mixture screws and/or increasing pilot jet size will usually cure the problem.

- NOTE: A rich problem gets worse as the engine heats up.

- If the throttle is lightly "blipped" at idle, and the rpm drops below the set idle speed, then rises up to the set idle speed, the low speed mixture screws are probably set too rich: try 1/2 turn in, to lean the idle mixture.

- NOTE: A lean problem gets better as the engine heats up.

- If the throttle is lightly "blipped" at idle, and the rpm "hangs up" before dropping to the set idle speed, and there are no intake leaks and the idle speed is set at less than 1000 rpm, the mixture screws are probably too lean: try 1/2 turn out, to richen mixture. Be sure there are no intake leaks and the idle speed is set at less than 1000 rpm!

- NOTE: A rich problem gets worse as the engine heats up.

- Fuel Screw setting (AKA mixture screws)

1983 GS 1100E w/ 1230 kit, .340 lift Web Cams, Ape heavy duty valve springs, 83 1100 head with 1.5mm oversized SS intake valves, 1150 crank, Vance and Hines 1150 SuperHub, Star Racing high volume oil pump gears, 36mm carebs Dynojet stage 3 jet kit, Posplayr's SSPB, Progressive rear shocks and fork springs, Dyna 2000, Dynatek green coils and Vance & Hines 4-1 exhaust.

1985 GS1150ES stock with 85 Red E bodywork.

Comment

- 1. Top end (full throttle / 7.5k to redline -

.png)

/

/

Comment