Can see the brushes are kinda short, down close to the wire connections.

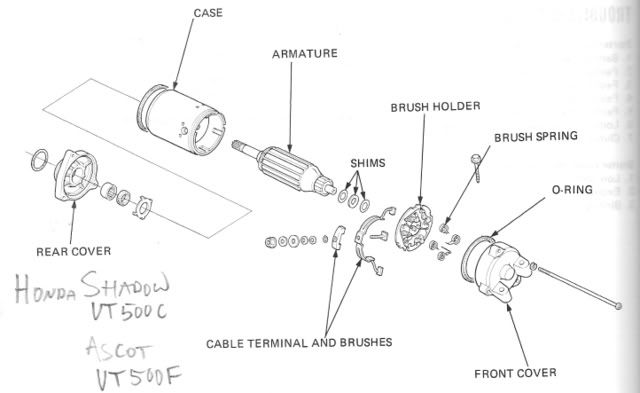

I see the wires from the ring that go into the motor (not pictured), but not seeing how to disconenct/reconect the wiring. At the ring? At the terminal and case ground somewhere? I did pull the ring out a little bit to look around.

Here are some pics showing some other things, and what I did.

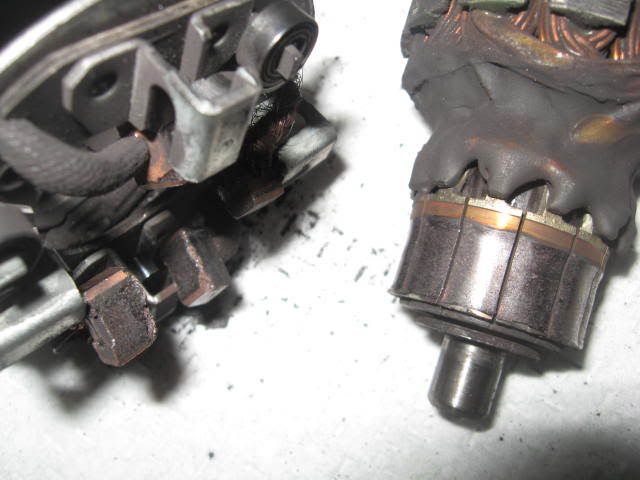

SHowing how much brush dust and chunks was inside there. Was also lots of brush dust packed in on the armature (rotor) and on the stator, not much clearance inbetween.

Showing how short the brushes are.

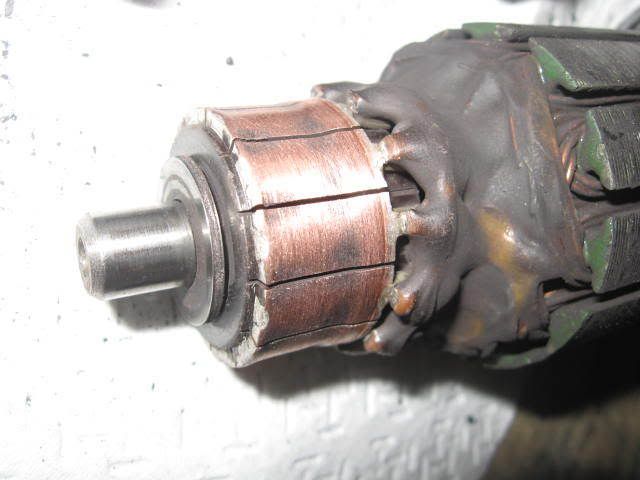

Showing commutator.

Commutator after I touched it up with 100 then 180 grit sandpaper. (Thought I had some emmory paper but couldnt find it right away.)

Ah, getting it back together was right at about the limit of my patients and manual dexterity. This little trick helped quite a lot: Took some little pieces of cable ties and used them to hold back the springs, then could put the brushes in place and they would stay back so could get rotor back in place. Some of the brushes I turned around because they were wore down right close to the wire attatcments and was more remaining bush length on other side of the wire (dont know if this good idea or not).

So I got it back together, and will reinstall tommorow and see if any better.

And I now know the brushes are short and need to be replaced. I know can get a set of brushes, or can get a kit with brushes and ring kit. But not seeing how to disconnect and reconnect the new ones.

Reason I am doing this is that sometimes the bike turns over fairly slow. Most often seems okay. Battery and charging are okay.

.

Comment