Josh

Announcement

Collapse

No announcement yet.

Argh! Can't remove lower steering bearing race!!!

Collapse

X

-

ironsheik

ironsheik

Argh! Can't remove lower steering bearing race!!!

Hey all. I got the top race out of the frame on my 83 1100ed but the bottom one won't come out easily. I cut it pretty deeply with my dremel but the angle doesn't really allow me to punch it any more with a chisel. I kind of mangled a small part of thee tube as well which sucks. I'll have to file some before the new race goes in. Anyway, I'm planning on using a bit of heat on the frame but there's no good way I can see to knock the race out from the top. The angle doesn't allow me a good place to tap on. Any tips would be appreciated.

JoshTags: None

-

I think that's why I left the old outer race in there and just slid the new inner race and bearing on the stem up into the old outer race. The new All Balls race seemed the same as the stock one.

Last edited by bonanzadave; 11-10-2008, 08:51 PM.82 1100 EZ (red)

Last edited by bonanzadave; 11-10-2008, 08:51 PM.82 1100 EZ (red)

"You co-opting words of KV only thickens the scent of your BS. A thief and a putter-on of airs most foul. " JEEPRUSTY

Comment

-

NICK!

NICK!

I took a really big straight blade screwdriver and beat just the very tip over until I could get on that bottom race from the top. Think I bent over only about 1/8", works like a charm.

Comment

-

Forum LongTimerBard Award Winner

GSResource Superstar

Past Site Supporter- Oct 2003

- 17468

- Indianapolis

I took a pry bar and bashed the plastic handle until it shattered and I had a nice hunk of metal. The angled tip reaches the top of the race perfectly.1983 GS850G, Cosmos Blue.

2005 KLR685, Aztec Pink - Turd II.3, the ReReReTurdening

2015 Yamaha FJ-09, Magma Red Power Corrupts...

Eat more venison.

Please provide details. The GSR Hive Mind is nearly omniscient, but not yet clairvoyant.

Celeriter equita, converteque saepe.

SUPPORT THIS SITE! DONATE TODAY!

Co-host of "The Riding Obsession" sport-touring motorcycling podcast at tro.bike!

Comment

-

mighty13d

mighty13d

if you have a welder handy and you're able to reach up in there, run a couple hot beads of weld right around the inside of the race and let it cool on it's own. after it cools you'll be able to pull on it with a finger and pull it out.

I've done this with a wheel bearing from my car. 12 ton press wouldn't remove it, so i grabbed the welder and once it cooled, i only had to drop the socket i was using to press it with onto it, and it fell right out!

Comment

-

Ditto, found a pry bar that is really more like large screwdriver with a bend about 2" above the blade. I fit in thru the top and pounded like helllOriginally posted by bwringer View PostI took a pry bar and bashed the plastic handle until it shattered and I had a nice hunk of metal. The angled tip reaches the top of the race perfectly.

Comment

-

Make two cuts about 1/4" or so apart. If you don't get quite all the way through on those cuts, the race is at least significantly weaker and you can hit the little piece out with a screwdriver. Once the piece is out, the rest of it will just about fall out.Originally posted by waltfen View PostCut all the way through it with the dremel and it will almost fall out.

.sigpic

mine: 2000 Honda GoldWing GL1500SE and 1980 GS850G'K' "Junior"

hers: 1982 GS850GL - "Angel" and 1969 Suzuki T250 Scrambler

#1 son: 1986 Yamaha Venture Royale 1300 and 1982 GS650GL "Rat Bagger"

#2 son: 1980 GS1000G

Family Portrait

Siblings and Spouses

Mom's first ride

Want a copy of my valve adjust spreadsheet for your 2-valve per cylinder engine? Send me an e-mail request (not a PM)

(Click on my username in the upper-left corner for e-mail info.)

Comment

-

dirtyfingers

dirtyfingers

Yep, prybar works good. But.....I found that the particularly hard ones would sometimes fall right out if you layed a bead of weld (with a MIG welder) and allowed them to cool. Cant be sloppy with the welding .

.

Comment

-

Forum LongTimerBard Award Winner

GSResource Superstar

Past Site Supporter- Oct 2003

- 17468

- Indianapolis

Mongo no have welder.

Mongo smash prybar. Smash Mongo smash! Pretty plastic handle go boom.

Then mongo bash prybar into bearing race with big hammer. Bash bash bash.

Soon, evil bearing race go ping on floor.

Mongo happy. 1983 GS850G, Cosmos Blue.

1983 GS850G, Cosmos Blue.

2005 KLR685, Aztec Pink - Turd II.3, the ReReReTurdening

2015 Yamaha FJ-09, Magma Red Power Corrupts...

Eat more venison.

Please provide details. The GSR Hive Mind is nearly omniscient, but not yet clairvoyant.

Celeriter equita, converteque saepe.

SUPPORT THIS SITE! DONATE TODAY!

Co-host of "The Riding Obsession" sport-touring motorcycling podcast at tro.bike!

Comment

-

Suzuki_Don

Suzuki_Don -

Good grief! All this work to get them out. How hard is it to install them?Dogma

--

O LORD, be gracious to me; heal me, for I have sinned against you! - David

Skeptical scrutiny is the means, in both science and religion, by which deep insights can be winnowed from deep nonsense. - Carl Sagan

--

'80 GS850 GLT

'80 GS1000 GT

'01 ZRX1200R

How to get a "What's New" feed without the Vortex, and without permanently quitting the Vortex

Comment

-

endlessGSgeek

endlessGSgeek

Special tool tip!!

This works:Originally posted by ironsheik View Post... there's no good way I can see to knock the race out from the top. The angle doesn't allow me a good place to tap on. Any tips would be appreciated.

Josh

find a 12" bolt, 5/8" thick

Pin a washer between two nuts on the threaded side. The washer should be THICK, and as big as you can find (that still makes it down to the race from the top). Orient the washer so that the sharp side of the washer (cut edged) aims down, for a better bite.

Find the lip, and use a hammer to hit it from above. The bigger the washer, the better your bite. ONCE the race begins to move, you can get the washer in deeper behind the race and it gets easier.

I saved hardware from a telephone pole (galvanized bolts) to do this. It works like a charm.

Good luck!

EndlessGSgeek

Comment

-

endlessGSgeek

endlessGSgeek

another special tool

Getting the new one in: just gently tap around the edge from below (lower race). Shave the old used race around the edge to make it slightly smaller (bench grinder), and then use the old race in the recess when the new race starts to go in recessed. This spreads out the impact and guides it in more straight.Originally posted by Dogma View PostGood grief! All this work to get them out. How hard is it to install them?

Comment

-

ironsheik

ironsheik

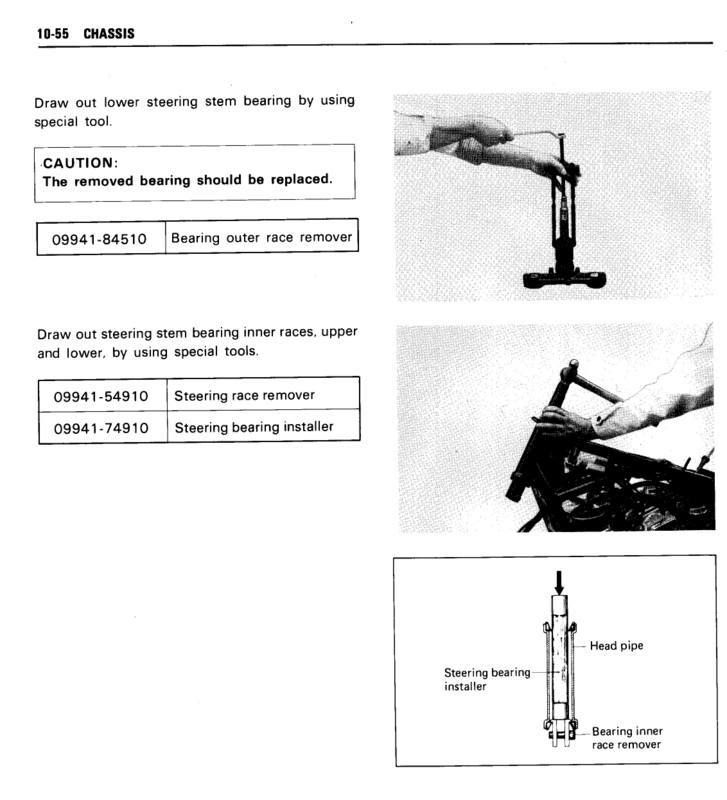

Thanks for all the tips. The next time I have to do this, I'm paying $60 for the Suzuki tool. I'll bet it's a piece of cake. I thought I learned long ago to use the right tool for the job but I guess I just didn't see the cost/benefit thing working out at $60 for a single use tool. Now I know it would have saved me a couple of hours of annoyance and damage to my bike. Oh well. I'm on my way to grab a proper pry bar now... Hopefully I didn't mangle the frame too much.

Comment

.png)

Comment