Announcement

Collapse

No announcement yet.

Valve Tappet too Small 1.6-1.8mm?

Collapse

X

-

Did you measure the depth of the shim pocket on top of the valve bucket? Obviously, you can't use a shim thinner than the height of the pocket.Ed

To measure is to know.

Mikuni O-ring Kits For Sale...https://www.thegsresources.com/_foru...ts#post1703182

Top Newbie Mistakes thread...http://www.thegsresources.com/_forum...d.php?t=171846

Carb rebuild tutorial...https://gsarchive.bwringer.com/mtsac...d_Tutorial.pdf

KZ750E Rebuild Thread...http://www.thegsresources.com/_forum...0-Resurrection

-

Roland

Roland

Shim Sizing

I didn't measure the pocket but I did specifically take note that the 1.75mm allows the Cam to clear the edge of the Tappet Ring or pocket.

For those of you reading this and wondering why it matters, it is because if the Cam makes contact with the edge of the Tappet it could scrape and scar up your cam.

Being cautious about thiss was what took me the longest to deal with, I had to remove one shim, swap it with another before I could turn the cam for the next test.

Comment

-

Man dude! I didn't even think of that!Originally posted by Roland View PostI didn't measure the pocket but I did specifically take note that the 1.75mm allows the Cam to clear the edge of the Tappet Ring or pocket.

For those of you reading this and wondering why it matters, it is because if the Cam makes contact with the edge of the Tappet it could scrape and scar up your cam.

Being cautious about thiss was what took me the longest to deal with, I had to remove one shim, swap it with another before I could turn the cam for the next test.1983 GS 1100E w/ 1230 kit, .340 lift Web Cams, Ape heavy duty valve springs, 83 1100 head with 1.5mm oversized SS intake valves, 1150 crank, Vance and Hines 1150 SuperHub, Star Racing high volume oil pump gears, 36mm carebs Dynojet stage 3 jet kit, Posplayr's SSPB, Progressive rear shocks and fork springs, Dyna 2000, Dynatek green coils and Vance & Hines 4-1 exhaust.

1985 GS1150ES stock with 85 Red E bodywork.

Comment

-

Roland

Roland

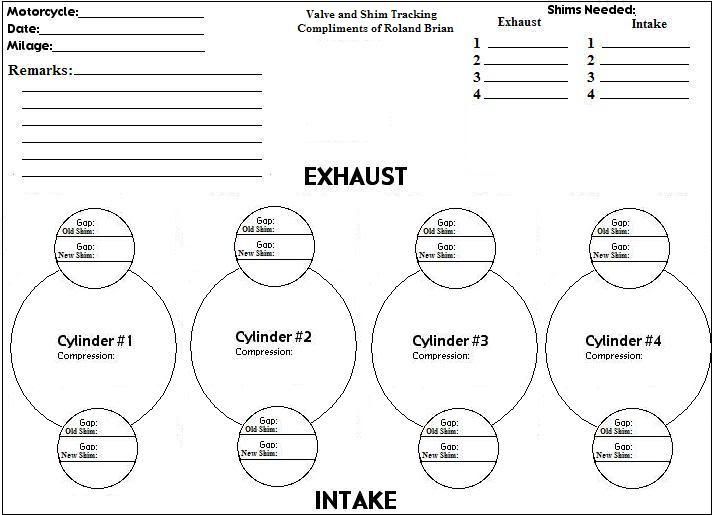

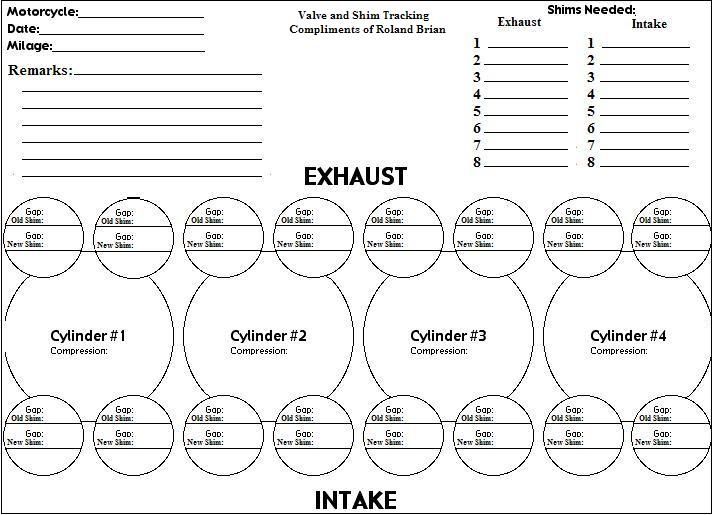

Shim Tracking Diagrams

While doing my search for my missing shim sizes, I came across a diagram to help track the valve adjustments. I modified it to suit my needs and then duplicated it in a 16 Valve version. I thought I would give a little back to all those that have helped me on the forum. I hope a few of you find these useful.

You can print these out to help you with your valve adjustments and tracking for future use.

Comment

-

Our member "Steve" has a good Excel program for that need.1983 GS 1100E w/ 1230 kit, .340 lift Web Cams, Ape heavy duty valve springs, 83 1100 head with 1.5mm oversized SS intake valves, 1150 crank, Vance and Hines 1150 SuperHub, Star Racing high volume oil pump gears, 36mm carebs Dynojet stage 3 jet kit, Posplayr's SSPB, Progressive rear shocks and fork springs, Dyna 2000, Dynatek green coils and Vance & Hines 4-1 exhaust.

1985 GS1150ES stock with 85 Red E bodywork.

Comment

-

almarconi

almarconi

My 16v engine has tappets not shims. I thought all 16v engines were the same.I modified it to suit my needs and then duplicated it in a 16 Valve version

Comment

-

Roland

Roland

Valve Tappet Clearance too Small

Well I tried a couple other relatively local bike shops looking for the shims to bring my bike fully withing spec. but no such luck. I contacted Alba yesterday and although they did have a few 29.5mm diameter shims they had very few and not sizes I needed.

I surrender and give up on surfing the net and determined if I am going to be Anal about getting my clearances within specs, I am going to have to grind them down myself or at least get some assistance at the RIT Mechanical Engineering Machine Shop.

I stopped in this morning with my spare 2.15mm shim and they helped me grind it down to 2.0.

Comment

-

Just so you know by grinding down the shim you are removing the hardened surface of the shim. You might want to consider putting the ground surface facing down and allow the unground hardened surface to contact the cam lobes.

I suspect this thread will come back to life in a few months and a few miles. When things are this far out there are bigger issues at work.78 GS1000 Yosh replica racer project

82 Kat 1000

10 990 ADV-R The big dirt bike

Some dirt bikes

Comment

-

Roland

Roland

Shims: How Close is Close enough

I love the RIT Machine Shop with the tools they have it makes even the strongest man drool. We started off using a Diamond tip to precisely smooth and flatten the grinding wheel then with precision I have never used before we ground my shim down with as small as .001mm steps from 2.15 until we had it to precisely 2.00mm. This was half the distance that I was expecting need to go but I wanted to be cautious.

With my 1.75mm shim I was measuring a gap between .30mm and .33. That was leading me to the idea to hit a happy medium of .05 I would need a shim around 2.00

So I ground down my 2.15 and now it is 2.00 on my # 1 Intake I am reading between .10 and .13 as Anal Retentive as I was being with my measurements the newly adjusted shim is .05 too small (WTF).

Anyhow I am starting to think this is close enough as over time it will build up carbon and become tighter or who know now that I have it much closer, maybe it will burn off some of the carbon that has been building up for 30+ years.

Below are my measurements now. Give me your opinions please. Are they close enough that I can put the new gasket on and permanently close her up or should I put back on my temporary gasket and run her for a while more and retest?

(Measurements are between the two numbers smaller number fits, bigger number does not)

Exhaust

#1 = 2.50mm Shim, Gap .15-.18

#2 = 2.60mm Shim, Gap .08-.10 (.09)

#3 = 2.60mm Shim, Gap .13-.15 (.14)

#4 = 2.55mm Shim, Gap .08-.10 (.09)

Intake

#1 = 2.00mm Shim, Gap .10-.13

#2 = 2.70mm Shim, Gap .06-.08 (.07)

#3 = 2.90mm Shim, Gap .06-.08 (.07)

#4 = 2.70mm Shim, Gap .04-.05

Comment

-

jjmaag

jjmaag

If this engine runs right, without the oil filter looking like a porcupine from the metal, you should get a mechanic of the year award.

Comment

-

My opinion is to adjust all the clearances to factory spec. Failing that, .10 mm max.Ed

To measure is to know.

Mikuni O-ring Kits For Sale...https://www.thegsresources.com/_foru...ts#post1703182

Top Newbie Mistakes thread...http://www.thegsresources.com/_forum...d.php?t=171846

Carb rebuild tutorial...https://gsarchive.bwringer.com/mtsac...d_Tutorial.pdf

KZ750E Rebuild Thread...http://www.thegsresources.com/_forum...0-Resurrection

Comment

-

Not completely GSR PC, but persistence paid off none the less and that is certainly GSR culture. I would grease the gasket rather than call it a permanent installOriginally posted by jjmaag View PostIf this engine runs right, without the oil filter looking like a porcupine from the metal, you should get a mechanic of the year award. .

.

At least it seems you have salvages the summer by not having to pull the head.

Pos

Comment

-

Roland

Roland

Well I don't know about that but if nothing else, at least most persistent.Originally posted by jjmaag View Postyou should get a mechanic of the year award.

BTW if after installing the previous shims I ran it for about 15mins in 3rd gear at 3500 rpm. After I removed the cover and gasket all the tappet Cam compartments were full of oil. AKA no problem with oil flow.

Comment

-

jjmaag

jjmaag

Just curious, did you check the compresson on that cylinder after you got it running? Also did the 2.00mm shim stick out out of the bucket at all?

Comment

.png)

Comment