All has gone smooth except for the fact that I broke 3 bolts off the cam cover (which required drilling BTW and after 2 successful extracts, the third one decided to not come out at all. In the end, I had a big missing piece off the cover)

Other notable moments:

-Dropping c-clip down into crank

-Dropping screw into transmission

-ACCIDENTALLY unscrewing of cylinder stud.( The nut securing it was covered in surface rust. After 2 nights of soaking I guess it worked itself all the way to the crank case portion as well. Now the damn thing is out and I don't know how many lbs to torque it back in at.)

-Breaking a piece of engine (There are two points at the front of the engine above the oil filter. On the right side is the beefy point where on the left side is the less beefy point. In hopes of securing a bolt and nut in and then tightening it to creation an expansion in hopes of trying to crack the crank halves together; the engine mount decided to snap instead. &@#%!@^# ensued.)

My current dilemma,

I can't for the life of me get the Alternator magnet off the crank. The manual says to utilize swingarm bolt and use free sliding weight to act as impact hammer. Well, I just about tried everything plus somemore, but the damn thing only budged about 1cm. Removal of this part is not necessary so I just left it there atm.

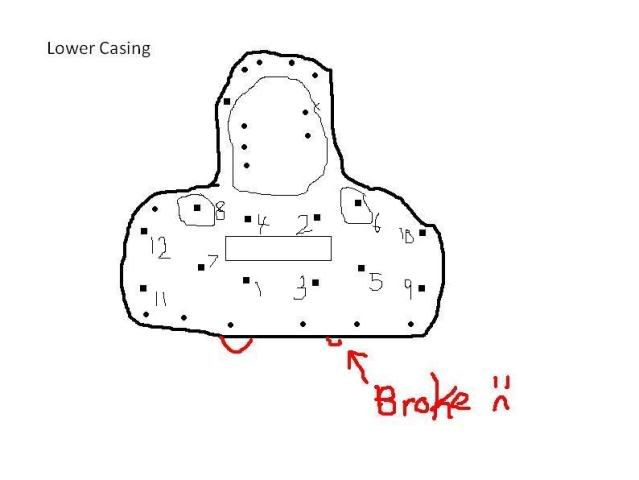

I can't seem to get the crankcase halves to separate. The manual states to rest engine upside down on cylinder studs and remove all the 12mm bolts in sequence followed by the 10mm bolts on the lower. What the manual failed to mention as well was that there is an extra 10mm bolt next to the oil sensor that also keeps the two halves together. As far as I can tell, everything is off but I still can't get the 2 halves to open. Are there any tips and tricks?

Much thanks to any tips or advice to assist in removal!

Thanks

.png)

Comment