Just noticed the swing arm (driveshaft tube) just before the flange that bolts to the differential flange is CRACKED at the weld all the way around and starting to seperate. Any body have this or see this? and can it be repaired. Other than that, it looks brand new. The paint is shiny, not even road nicks. What happened? I can't stop crying.

Announcement

Collapse

No announcement yet.

Ouch! anybody have crack?

Collapse

X

-

nert

nert

Ouch! anybody have crack?

82' 1100GLZ clean, spirited but never abused.

Just noticed the swing arm (driveshaft tube) just before the flange that bolts to the differential flange is CRACKED at the weld all the way around and starting to seperate. Any body have this or see this? and can it be repaired. Other than that, it looks brand new. The paint is shiny, not even road nicks. What happened? I can't stop crying.Tags: None

-

Poot

Poot

I think this is terminal for your swingarm , if its that big of a crack.

Heres a possible solution: http://cgi.ebay.com/ebaymotors/ws/eB...504472196&rd=1

I think that this swingarm from a 1980 GS 850, will work with your 1100, but I'm not 100% sure. I could give you dimensions of my swingarm, to compare them with yours, if you like.

poot

-

nert

nert

thanks Poot

looks the same. BikeBandit has a differant part number for my 1100G

than the one the fella lists for the 850. I am assuming your swing arm is still installed. I think dimensions would be very difficult.

Does any one out There is GS land know if thy will interchange?

Comment

-

Forum LongTimerCharter Member

GSResource Superstar

Past Site Supporter- May 2002

- 17921

- The only Henniker on earth

Wow, that's scary. Just about the only thing that makes me nervous about my old bike are failures like this.

Here at work (light gauge steel construction engineering) the latest buzz has been concerning repetitive, rythmic force cycles (like the forces created by the constant thumping of a manufacturing machine, or the forces created by a door closing 25000 times). The calculations required to determine these values would make your head spin!

I just can't think like an engineer when I ride my bike. I'd go insane.Currently bikeless

'81 GS 1100EX - "Peace, by superior fire power."

'06 FZ1000 - "What we are dealing with here, is a COMPLETE lack of respect for the law."

I ride, therefore I am.... constantly buying new tires.

"Tell me what kind of an accident you are going to have, and I will tell you which helmet to wear." - Harry Hurt

Comment

-

nert

nert

not engineer, but a truck and specialty equipment mechanic for 35 years. I hear what your saying. If every one knew what we know (and don't know) there would be a lot less traffic.

Comment

-

ddz

ddz

Comment

-

Anonymous

Anonymous

I think that I read somewhere that the 1100 shaft is a little bit longer than the one used on the GS850, but I'm not sure.

Nick Diaz knows a lot about 850's and 1100's. Perhaps you should send him an email or PM.

Comment

-

SqDancerLynn1

SqDancerLynn1 -

Forum LongTimerBard Award Winner

GSResource Superstar

Past Site Supporter

Super Site Supporter- Oct 2003

- 17441

- Indianapolis

Just to satisfy our morbid curiosity, can you take a picture of the crack and post it?

It's most likely a defective weld, but you can't be too surprised at anything on a 20+ year old bike.

I always get a good light and take a hard look at the frame welds when I have the tank off.

Gives me the willies just to think about it...1983 GS850G, Cosmos Blue.

2005 KLR685, Aztec Pink - Turd II.3, the ReReReTurdening

2015 Yamaha FJ-09, Magma Red Power Corrupts...

Eat more venison.

Please provide details. The GSR Hive Mind is nearly omniscient, but not yet clairvoyant.

Celeriter equita, converteque saepe.

SUPPORT THIS SITE! DONATE TODAY!

Co-host of "The Riding Obsession" sport-touring motorcycling podcast at tro.bike!

Comment

-

nert

nert

thanks for the hummor SqDancerLynn1

I will take a photo tomorrow, as i had to walk home today from work 32 miles, didn't think i should continue to ride it that way. (really, i borrowed a shop truck)

If i can figure out how to attach (the photo) i will.

Big suprise. Bought the bike September 03 with 11,000 miles. Very clean, excellent condition. I added another 8,000 miles thus far just going back and forth to work etc. No time for weekend rides. I have to guess it let go almost all at once. I keep it clean and inspect things closely. As i walk by it in my shop i am always taking a towel to it. And there it was. On the way to work this morning the only thing i felt was, like a little tire squirm on an off ramp. Really didn't think too much of it as i am due for tires. When i saw the crack/gap, I was *@%^$*@%^$*@%^$*@%^$ed, miffed, and scared. In that order.

thanks for the support.

Comment

-

Poot

Poot

well nert, I just happen to have my swingarm dissasembled now, so I will measure it for you. Hopefully it works.

It must be a defective weld, because it would take a pretty big bump to crack that thing...

Comment

-

Forum LongTimerCharter Member

GSResource Superstar

Past Site Supporter- May 2002

- 19277

- Toronto, Canada

Originally posted by Pootwell nert, I just happen to have my swingarm dissasembled now, so I will measure it for you. Hopefully it works.

It must be a defective weld, because it would take a pretty big bump to crack that thing...

The weld itself should be nominally stronger than the rest of the material, so, if the weld itself is broken, I would be inclined to agree with Poot.

That said, a complete repair would require removal of the defective material, and having it re-welded.

A lesser quality repair would simply see it re-welded, as is. This would work, and if done properly will last a long time, but welding is not always as simple as it appears.

You should note that it might leave a slight change in angle, if the pieces are not firmly pressed in place before being welded, and held there during the welding.

Additionally, you would be welding metal that has already been stressed and weakened to its breaking point, not just at the crack itself but all the metal around it. Apart from essential cleaning, it would have to be thoroughly and evenly pre-heated to ensure a decent weld resulted. If this is not done, the remaining weak metal continues to be exactly that, and a new weld could look good, but the metal is prone to failure.

The problem you face, if choosing this repair route, is finding a welder of sufficient skill, AND work ethic, to do it properly.

I know professional welders have the same basic licence qualifications, but in real life they specialize in different things, and what you need done may be outside of the experience of many.

Some welders, when faced with something quite different, often overlook essential details or try to shorten the set-up time, or avoid making necessary jigs, with negative results.

Final point: our bikes are not young, and parts are available at relatively low cost. This means that if you do find a good welding shop nearby, you may find the repair cost will be similar to obtaining a replacement unit, also as Poot suggested.Bertrand Russell: 'Men are born ignorant, not stupid. They are made stupid by education.'

Comment

-

nert

nert

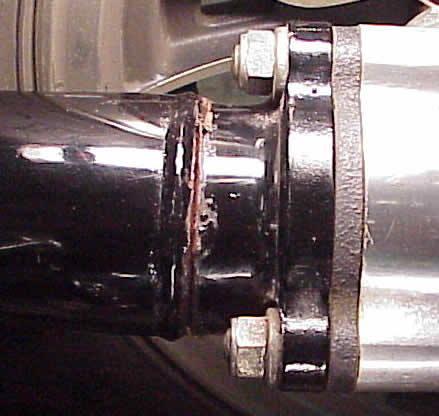

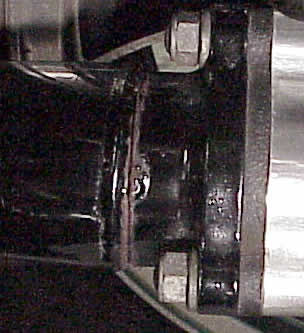

careful and relaxed inspection reveals a nice clean break folloing the edge of the weld. So straight and even, looks like it could have been cut with a pipe cutter.

The good news is one FINE and OUTSTANDING gsResources member is sending me a a used swingarm/torque tube from a 82' 1100gk for the cost of shipping. Doesn't get better than that. That actually pays for my subscription as a gsResource member!!

Comment

-

Forum LongTimerBard Award Winner

GSResource Superstar

Past Site Supporter

Super Site Supporter- Oct 2003

- 17441

- Indianapolis

Nert sent me some photos to post. Don't look if you have a weak stomach!

An overview of the problem:

Close-up #1:

Close-up #2:

Nert's subtle reminder to himself not to ride until it's fixed:

Scary!1983 GS850G, Cosmos Blue.

2005 KLR685, Aztec Pink - Turd II.3, the ReReReTurdening

2015 Yamaha FJ-09, Magma Red Power Corrupts...

Eat more venison.

Please provide details. The GSR Hive Mind is nearly omniscient, but not yet clairvoyant.

Celeriter equita, converteque saepe.

SUPPORT THIS SITE! DONATE TODAY!

Co-host of "The Riding Obsession" sport-touring motorcycling podcast at tro.bike!

Comment

-

Katamaniac

Katamaniac

It looks as though the part broke in the Heat Affetcted Zone of the weld. What happens when you weld is you inherantly put stresses into the metal along side the weld (the toe of the weld). That is a very common area for welds to crack. I work in an Oil Refinery as an Inspector and see stress cracks like these a lot.

With that said, any compitant welder can reweld that up for you. I would have it TIG welded, since that process places the lowest residual stresses into the metal.

One thing you want to make sure of if you get it welded, is that the welder blends the weld into the base metal without creating any undercut.

The reason for that is, if there is an abrupt change in direction (i.e. the weld meets the base metal at a shrp angle) you get what is called Stress Risers. Undercut is basically the loss of wall thickness at the edge (Toe) of the weld.

The weld spatter on the base metal also creates stresses. Those can tend to be worse than the weld itself.

Comment

.png)

Comment