Announcement

Collapse

No announcement yet.

1150 EF updating project

Collapse

X

-

drhach

drhach

So you adapted a 3-wire sensor? That was the solution that I came up with as well. I'm using a similar Bosch unit from a Saab. I didn't really see a way to get the 4-wire unit to work either.

-

It´s a 3-wire sensor . The Volvo sensor I have could be similar as yours .Originally posted by drhach View PostSo you adapted a 3-wire sensor? That was the solution that I came up with as well. I'm using a similar Bosch unit from a Saab. I didn't really see a way to get the 4-wire unit to work either.

Mine is not a original Bosch it´s Hügo´s "replica" , but it works .

What ECU you have ?

Comment

-

drhach

drhach

I have the megasquirt, I believe it is a Version 2. It is the last version before spark control became an option. It is actually intended for my old BMW (R90), but I am thinking more and more that I might like to EFI my GS1000 too. One thing at a time though.

Comment

-

Project continues . Target is to get more power .

Cylinder block is bored to +1 mm oversize pistons ( SGP ) , plenum modified ( less volume and better flow ) , a ported supercharger and more boost after break in .

I´m going to continue with original cams , which are now adjusted :

intake 2 degr. retarded and exhaust 2 degr advanced .

Comment

-

Hey Blower, thanks for the feedback.

I see from your original post that you are running an Eaton M45 SC. What is the maximum boost available from this unit? The manufacturers recommend a max of 14,000 rpm for their SC. Do you have any rpm figures for maximum efficiency? At 30% increase over crank rpm, you're already close to their recommended limit.

Are you enlarging the outlet or inlet ports or just shaping/blending radii ? What's the reasoning behind this?:) The road to hell is paved with good intentions......................................

GS 850GN JE 894 10.5-1 pistons, Barnett Clutch, C-W 4-1, B-B MPD Ignition, Progressive suspension, Sport Demons. Sold

GS 850GT JE 1023 11-1 pistons. Sold

GS1150ES3 stock, V&H 4-1. Sold

GS1100GD, future resto project. Sold

http://i155.photobucket.com/albums/s...s/P1000001.jpg

http://i155.photobucket.com/albums/s...s/P1000581.jpg

Comment

-

Originally posted by 49er View PostHey Blower, thanks for the feedback.

I see from your original post that you are running an Eaton M45 SC. What is the maximum boost available from this unit? The manufacturers recommend a max of 14,000 rpm for their SC. Do you have any rpm figures for maximum efficiency? At 30% increase over crank rpm, you're already close to their recommended limit.

Are you enlarging the outlet or inlet ports or just shaping/blending radii ? What's the reasoning behind this?

I think the max boost in my case can be near 10 psi .

I have a redline in 9000 rpm , so the SC spins 11700 rpm and the boost is 6 psi

and it needs 14 hp from crank.

When I increase SC to spinning 38 % over crank rpm it spins 12420 rpm and the boost

rises to 8 psi . SC takes 19 hp from crank .

Inlet port is "polished" , I only smooth the rough surface .

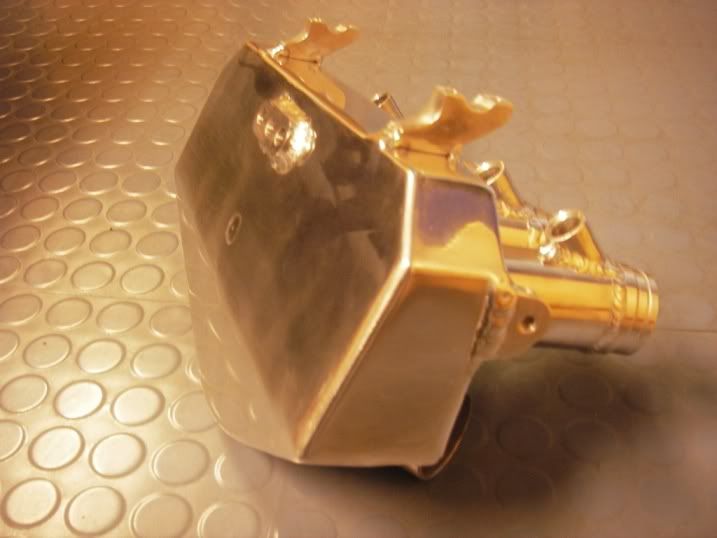

Outlet port is enlarged to Y shape , like in this picture :

Porting the SC reduces the boost heat (maybe) .

Comment

-

You can certainly do with a reduction in the Delta T if you intend to increase the SC speed to 12,420 rpm. The CAPA chart indicates a figure of 155 deg F at that rpm.Originally posted by Blower View PostI think the max boost in my case can be near 10 psi .

I have a redline in 9000 rpm , so the SC spins 11700 rpm and the boost is 6 psi

and it needs 14 hp from crank.

When I increase SC to spinning 38 % over crank rpm it spins 12420 rpm and the boost

rises to 8 psi . SC takes 19 hp from crank .

Inlet port is "polished" , I only smooth the rough surface .

Outlet port is enlarged to Y shape , like in this picture :

Porting the SC reduces the boost heat (maybe) .

It shouldn't harm your cause by smoothing out the rough inlet port surfaces, although on really smooth head ports, fuel droplets form on the shinny surface and reduce natural atomisation. The action and shape of your impellors should guarantee good atomisation from that point on though.

The enlarged Y exhaust port should reduce friction, but it may also affect efficiency. Looks like a 10%-15% increase in port window.

Good on you for having a go, you won't know until you try it.:) The road to hell is paved with good intentions......................................

GS 850GN JE 894 10.5-1 pistons, Barnett Clutch, C-W 4-1, B-B MPD Ignition, Progressive suspension, Sport Demons. Sold

GS 850GT JE 1023 11-1 pistons. Sold

GS1150ES3 stock, V&H 4-1. Sold

GS1100GD, future resto project. Sold

http://i155.photobucket.com/albums/s...s/P1000001.jpg

http://i155.photobucket.com/albums/s...s/P1000581.jpg

Comment

-

The "Y-bottom" area I ported out is not important for impellers , because there is a 0.002" gap between the impellers and the housing . That 1" wide "Y-bottom" area had a cast surface , not machined .

There is only air , which passes thru SC not air/fuel mixture . I´ve got a Megasquirt EFI and TPI injection .

If it needs a boost cooling I´m going to install a water/methanol injection and inject before the SC .

The max boost temperature was about 110 deg F over ambient temperature in 6 psi .

Comment

-

I was forgetting that the SC is blowing through. The water/ methanol injection upstream of the SC may be a good idea. That way, you will help increase the density of the charge and possibly increase the HP output by more than the realistic 40% claimed by CAPA.Originally posted by Blower View PostThe "Y-bottom" area I ported out is not important for impellers , because there is a 0.002" gap between the impellers and the housing . That 1" wide "Y-bottom" area had a cast surface , not machined .

There is only air , which passes thru SC not air/fuel mixture . I´ve got a Megasquirt EFI and TPI injection .

If it needs a boost cooling I´m going to install a water/methanol injection and inject before the SC .

The max boost temperature was about 110 deg F over ambient temperature in 6 psi .

110 deg F at those rpms isn't too bad when compared to some other compressors. Do you know what the max efficiency is for the M45 ?

It's certainly producing a reasonably flat torque curve from your dyno printout.

M45 units were sold originally with a choice of 2 bypass valves. One was designed for mounting on the intake port, the second for remote mounting.

Here's some related research http://www.capa.com.au/library_vortech_testing.htm:) The road to hell is paved with good intentions......................................

GS 850GN JE 894 10.5-1 pistons, Barnett Clutch, C-W 4-1, B-B MPD Ignition, Progressive suspension, Sport Demons. Sold

GS 850GT JE 1023 11-1 pistons. Sold

GS1150ES3 stock, V&H 4-1. Sold

GS1100GD, future resto project. Sold

http://i155.photobucket.com/albums/s...s/P1000001.jpg

http://i155.photobucket.com/albums/s...s/P1000581.jpg

Comment

-

Originally posted by 49er View PostI was forgetting that the SC is blowing through. The water/ methanol injection upstream of the SC may be a good idea. That way, you will help increase the density of the charge and possibly increase the HP output by more than the realistic 40% claimed by CAPA.

110 deg F at those rpms isn't too bad when compared to some other compressors. Do you know what the max efficiency is for the M45 ?

It's certainly producing a reasonably flat torque curve from your dyno printout.

M45 units were sold originally with a choice of 2 bypass valves. One was designed for mounting on the intake port, the second for remote mounting.

Here's some related research http://www.capa.com.au/library_vortech_testing.htm

The M45 max efficiency is 67% and its available in pressure ratio 1.3 - 1.46 in SC speed 4600 rpm - 7000 rpm .

Here : http://www.rbracing-rsr.com/turbotech.html#eaton are more charts .

Comment

-

Exellent link for comparing compressor maps for turbos. Only Vortech SC maps shown. I liked the secrets and oscars links.Originally posted by Blower View PostThe M45 max efficiency is 67% and its available in pressure ratio 1.3 - 1.46 in SC speed 4600 rpm - 7000 rpm .

Here : http://www.rbracing-rsr.com/turbotech.html#eaton are more charts .

Good luck with your results after doing those port mods.Last edited by 49er; 02-09-2009, 01:50 PM.:) The road to hell is paved with good intentions......................................

GS 850GN JE 894 10.5-1 pistons, Barnett Clutch, C-W 4-1, B-B MPD Ignition, Progressive suspension, Sport Demons. Sold

GS 850GT JE 1023 11-1 pistons. Sold

GS1150ES3 stock, V&H 4-1. Sold

GS1100GD, future resto project. Sold

http://i155.photobucket.com/albums/s...s/P1000001.jpg

http://i155.photobucket.com/albums/s...s/P1000581.jpg

Comment

-

CB900SS

CB900SS

Wow! Awesome bike, its really amazing what you have done.

Any video yet? I would love to hear that creation run!

Comment

.png)

Comment