What compression ratio are you running on this engine? You may be over advanced down low, causing detonation. If it's detonating just off idle, that will give a flat response too. Try retarding the spark a couple of degrees and then retest it. If the pinging stops, but you loose some mid range/top end torque, then you need to use higher octane fuels or fit an adjustable advance curve electronic ignition to correct this.

Announcement

Collapse

No announcement yet.

Fine tuning an 850

Collapse

X

-

Don, if you have an air leak/leaks your idle should hang up for a short period after closing the throttle. I would also expect your plugs to be showing a lean colour, which they don't.Originally posted by Suzuki_Don View Post

What compression ratio are you running on this engine? You may be over advanced down low, causing detonation. If it's detonating just off idle, that will give a flat response too. Try retarding the spark a couple of degrees and then retest it. If the pinging stops, but you loose some mid range/top end torque, then you need to use higher octane fuels or fit an adjustable advance curve electronic ignition to correct this.:) The road to hell is paved with good intentions......................................

GS 850GN JE 894 10.5-1 pistons, Barnett Clutch, C-W 4-1, B-B MPD Ignition, Progressive suspension, Sport Demons. Sold

GS 850GT JE 1023 11-1 pistons. Sold

GS1150ES3 stock, V&H 4-1. Sold

GS1100GD, future resto project. Sold

http://i155.photobucket.com/albums/s...s/P1000001.jpg

http://i155.photobucket.com/albums/s...s/P1000581.jpg

-

Suzuki_Don

Suzuki_Don

Yes Ian I agree, you make perfect sense. It's good to have a clear head when mine is getting all muddled.Originally posted by 49er View PostDon, if you have an air leak/leaks your idle should hang up for a short period after closing the throttle. I would also expect your plugs to be showing a lean colour, which they don't.

I am running 9.5:1 compression ratio. When I changed to 98 octane the pinging decreased a bit but is still there. If I'm really gentle, gradually opening the throttle I can get away without it pinging, but coming out of a corner on an uphill grade it's really hard to stop it pinging at all. Remember I have a points, condensor setup and the timing is set for the original 550 motor - timing marks, etc. I should probably clean the points up and rotate the whole baseplate a few degrees to retard the timing somewhat.What compression ratio are you running on this engine? You may be over advanced down low, causing detonation. If it's detonating just off idle, that will give a flat response too. Try retarding the spark a couple of degrees and then retest it. If the pinging stops, but you loose some mid range/top end torque, then you need to use higher octane fuels or fit an adjustable advance curve electronic ignition to correct this.

Below are the details of both ignition timing setups. Mine is currently set up on the GS550 specs. which would mean below 1500 rpm it is advanced 7 degrees more than would be ideal. But with conventional points setup I won't be able to get the timing perfect.

GS650E

Ignition Timing .................................................. ..... 10° B.T.D.C. below 1 650 r/min and

.................................................. ...............................40° B.T.D.C. above 3 500 r/min

GS550

Ignition Timing .................................................. ..... 17° B.T.D.C. below 1 500 r/min and

.................................................. ...............................37° B.T.D.C. above 2 500 r/minLast edited by Guest; 06-28-2011, 08:29 PM.

Comment

-

Don, your 9.5-1 CR isn't high enough to warrant running anything higher than 91 RON.I am running 9.5:1 compression ratio. When I changed to 98 octane the pinging decreased a bit but is still there. If I'm really gentle, gradually opening the throttle I can get away without it pinging, but coming out of a corner on an uphill grade it's really hard to stop it pinging at all. Remember I have a points, condensor setup and the timing is set for the original 550 motor - timing marks, etc. I should probably clean the points up and rotate the whole baseplate a few degrees to retard the timing somewhat.

Below are the details of both ignition timing setups. Mine is currently set up on the GS550 specs. which would mean below 1500 rpm it is advanced 7 degrees more than would be ideal. But with conventional points setup I won't be able to get the timing perfect.

GS650E

Ignition Timing .................................................. ..... 10° B.T.D.C. below 1 650 r/min and

.................................................. ...............................40° B.T.D.C. above 3 500 r/min

GS550

Ignition Timing .................................................. ..... 17° B.T.D.C. below 1 500 r/min and

.................................................. ...............................37° B.T.D.C. above 2 500 r/min

_

Are you saying that you're still running the 550E points system, including the centrifugal advance, but that you have timed it to the 650 specs? If so, that is your problem. Try retarding the spark by at least 5 degs and take the bike for another run. The longer stroke and different chamber/piston dome configurations won't be suitable for that advance rate. You may need to do some mixing and matching of the centrifugal advance mechanisms and the weights/springs too.:) The road to hell is paved with good intentions......................................

GS 850GN JE 894 10.5-1 pistons, Barnett Clutch, C-W 4-1, B-B MPD Ignition, Progressive suspension, Sport Demons. Sold

GS 850GT JE 1023 11-1 pistons. Sold

GS1150ES3 stock, V&H 4-1. Sold

GS1100GD, future resto project. Sold

http://i155.photobucket.com/albums/s...s/P1000001.jpg

http://i155.photobucket.com/albums/s...s/P1000581.jpg

Comment

-

Suzuki_Don

Suzuki_Don

Originally posted by 49er View PostDon, your 9.5-1 CR isn't high enough to warrant running anything higher than 91 RON.I am still running the original 550 points on backplate setup and it is timed to the original 550 timing marks and has been done statically. It has the original mechanical advance/retard with bob weights, springs, etc. It is not timed to 650 specs as there are no marks on the centrifugal unit for the 650.Originally posted by 49er View Post

Are you saying that you're still running the 550E points system, including the centrifugal advance, but that you have timed it to the 650 specs? If so, that is your problem. Try retarding the spark by at least 5 degs and take the bike for another run. The longer stroke and different chamber/piston dome configurations won't be suitable for that advance rate. You may need to do some mixing and matching of the centrifugal advance mechanisms and the weights/springs too.

Is there a specific way to retard the timing exactly 5 degrees or do I just undo the three screws holding the base plate and move the plate 4mm or so to retard the timing by guess work, etc.

Also I noticed that the points centrifugal advance unit can only advance the timing by 20 degrees and the 650 transistorised system can advance it by 30 degrees.

And Ian thanks for giving me the job of swapping springs and bob weights. This is a joyous job no doubt. Could anyone who has any spare bob weights send them to me please?

I do have the centrifugal advance/retard unit off a GS650, but of course it does not have the cam to open and close the points, but I may be able to use the springs and bob weights from it.

Going by my calculations if I retard the timing by rotating the base plate 5 degrees so things are better at small throttle settings then the timing higher up the rev range will be retarded by the same amount which means it will be advanced by only 32 degrees, whereas the 650 timing is quoted at 40 degrees of advance above 1650rpm. Is this going to cause a problem -- being too retarded at high revs and wide throttle openings.

Thanks again for all help given.Last edited by Guest; 06-28-2011, 11:48 PM.

Comment

-

Hey Don, life gets tedious , don't it?

If you're running a 650 crank in your 550 cases, why can't you use the electronic ignition components made for that setup? You should have minimal tuning challenges this way.

If you do choose to persevere with the points and weights, use a fine tipped felt pen to mark the edge of your backing plate at a point adjacent on the ali housing. I use the crankcase joint seam as my reference. Now just back off the static timing as much as it takes to prevent pinging. You may run out of adjustment on the backing plate and need to extend the slots to achieve the desired timing position. Once you've found this point, use the pen to mark the housing. You now have a distance that you can calculate and convert into degrees of crank rotation, or you can use a degree wheel to confirm the exact figure. The figure isn't important, but finding the correct static advance is.

At present, you are starting too advanced and continuing that way as the revs increase. The 550 weights will be lighter than would be required for the slower acceleration of the 650 crank. So you need to add some weight or fit stronger springs.

I would save yourself some agro and fit up a 650 electronic unit if its available.

One benefit is that you get a more accurate advance curve, up to 3500 rpm instead of the 2500 rpm with the 550 centrifugal advance system. As an example, the Boyer Bransden system I run on my 850 isn't fully advanced until around 4500 rpm.

Hey, it's decision time mate.:) The road to hell is paved with good intentions......................................

GS 850GN JE 894 10.5-1 pistons, Barnett Clutch, C-W 4-1, B-B MPD Ignition, Progressive suspension, Sport Demons. Sold

GS 850GT JE 1023 11-1 pistons. Sold

GS1150ES3 stock, V&H 4-1. Sold

GS1100GD, future resto project. Sold

http://i155.photobucket.com/albums/s...s/P1000001.jpg

http://i155.photobucket.com/albums/s...s/P1000581.jpg

Comment

-

Suzuki_Don

Suzuki_Don

Ian, I am running a standard 550 bottom end in this motor. The 550 and 650 (673cc) have the same stroke. The 650E has the same roller bottom end and crank as the 550, whereas the 650G has a different crank with slipper/shell bearings - but still the same stroke. The two 650 engines are essentially totally different motors. Not many parts will swap from the bottom end/crankcases on these models. Although the top ends are the same - pistons, cylinders, head, cams, etc.Originally posted by 49er View PostHey Don, life gets tedious , don't it?

If you're running a 650 crank in your 550 cases, why can't you use the electronic ignition components made for that setup? You should have minimal tuning challenges this way.

If you do choose to persevere with the points and weights, use a fine tipped felt pen to mark the edge of your backing plate at a point adjacent on the ali housing. I use the crankcase joint seam as my reference. Now just back off the static timing as much as it takes to prevent pinging. You may run out of adjustment on the backing plate and need to extend the slots to achieve the desired timing position. Once you've found this point, use the pen to mark the housing. You now have a distance that you can calculate and convert into degrees of crank rotation, or you can use a degree wheel to confirm the exact figure. The figure isn't important, but finding the correct static advance is.

At present, you are starting too advanced and continuing that way as the revs increase. The 550 weights will be lighter than would be required for the slower acceleration of the 650 crank. So you need to add some weight or fit stronger springs.

I would save yourself some agro and fit up a 650 electronic unit if its available.

One benefit is that you get a more accurate advance curve, up to 3500 rpm instead of the 2500 rpm with the 550 centrifugal advance system. As an example, the Boyer Bransden system I run on my 850 isn't fully advanced until around 4500 rpm.

Hey, it's decision time mate.

As I still am running the 550 crank will the advance curve of the current set-up be OK (bob weights & springs) as opposed to your suggestion that this set-up would advance too quickly for the slower accelerating 650 crank? The only real difference is the quench type combustion chambers with different burn characteristics = different ign timing.

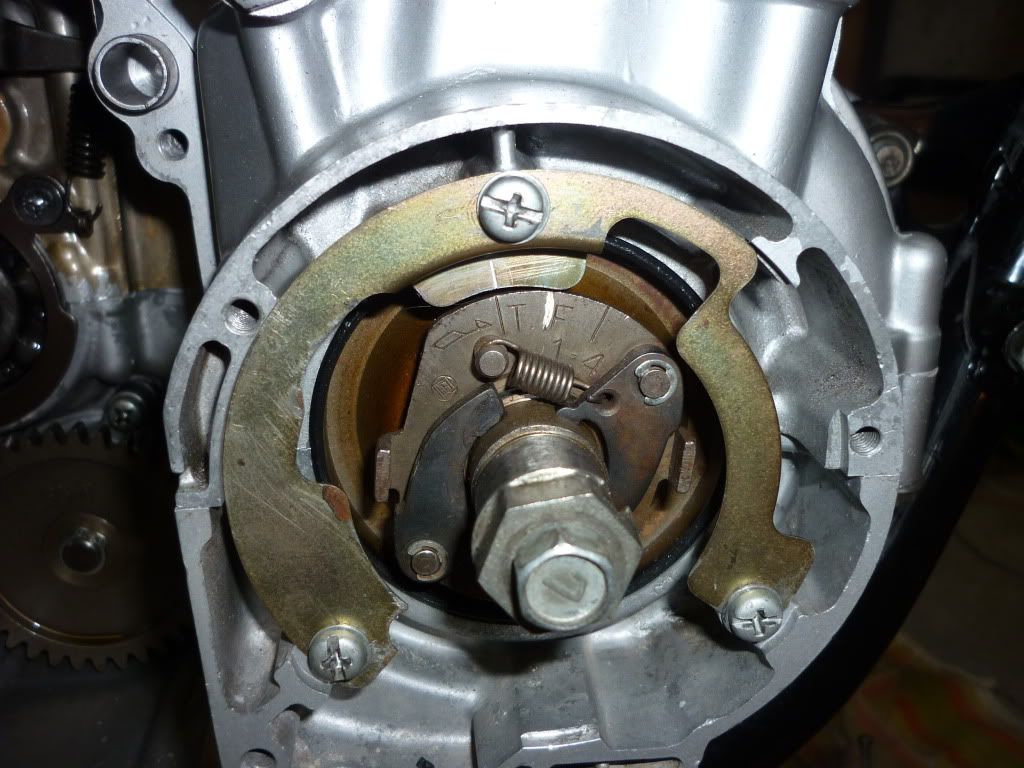

I do have the advance/retard unit off a 650G as pictured below. I also have the plate that bolts in place of my points plate with the two electronic modules (triggering device) as well with it's wiring. But I do not have the black box/igniter.

Would I be better off with a DYNA electronic system? But I would still be using the same advance/retard unit wouldn't I? If so which DYNA set-up would I need? Does the DYNA have a black box or are all the components under the points cover?

Is it correct to turn the points base plate clockwise to retard the ignition timing?

Ian is the advance curve on your Boyer system done mechanically or electronically?

ThanksLast edited by Guest; 06-29-2011, 07:21 PM.

Comment

-

Don, sorry I didn't realise that you got your extra capacity from bore increase alone. So, you are still running the 550 crank and rods, but 650 pistons, cylinders, head and cams.Originally posted by Suzuki_Don View PostIan, I am running a standard 550 bottom end in this motor. The 550 and 650 (673cc) have the same stroke. The 650E has the same roller bottom end and crank as the 550, whereas the 650G has a different crank with slipper/shell bearings - but still the same stroke. The two 650 engines are essentially totally different motors. Not many parts will swap from the bottom end/crankcases on these models. Although the top ends are the same - pistons, cylinders, head, cams, etc.

As I still am running the 550 crank will the advance curve of the current set-up be OK (bob weights & springs) as opposed to your suggestion that this set-up would advance too quickly for the slower accelerating 650 crank? The only real difference is the quench type combustion chambers with different burn characteristics = different ign timing.

I do have the advance/retard unit off a 650G as pictured below. I also have the plate that bolts in place of my points plate with the two electronic modules (triggering device) as well with it's wiring. But I do not have the black box/igniter.

Would I be better off with a DYNA electronic system? But I would still be using the same advance/retard unit wouldn't I? If so which DYNA set-up would I need? Does the DYNA have a black box or are all the components under the points cover?

Is it correct to turn the points base plate clockwise to retard the ignition timing?

Ian is the advance curve on your Boyer system done mechanically or electronically?

Thanks

If your compression ratio figure is correct, it appears that the combustion chamber design requires less static advance but more total advance for the stock 650 configuration.

To remedy your detonation, you still need to retard your static position by rotating the backing plate in the same direction as the rotor turns (clockwise). Try this and road test again. If you find that the mid range punch is lacking, you will need to modify the centrifugal advance mechanism, or fit the 650G advance unit. Do you know the stock ignition timing specs for the 650G? I'm picking that the mechanical advance will throw out further than the 550 unit to gain the 40 degs total advance required for stock engines.

You would need to invest in a Dyna 2000 electronic unit to plot your own advance curve. The BB units are factory set, but are electronically advanced.

I suggest you retard what you've got first to get some feed back. :) The road to hell is paved with good intentions......................................

:) The road to hell is paved with good intentions......................................

GS 850GN JE 894 10.5-1 pistons, Barnett Clutch, C-W 4-1, B-B MPD Ignition, Progressive suspension, Sport Demons. Sold

GS 850GT JE 1023 11-1 pistons. Sold

GS1150ES3 stock, V&H 4-1. Sold

GS1100GD, future resto project. Sold

http://i155.photobucket.com/albums/s...s/P1000001.jpg

http://i155.photobucket.com/albums/s...s/P1000581.jpg

Comment

-

Suzuki_Don

Suzuki_Don

Yes, correct in every aspect.Originally posted by 49er View PostDon, sorry I didn't realise that you got your extra capacity from bore increase alone. So, you are still running the 550 crank and rods, but 650 pistons, cylinders, head and cams.

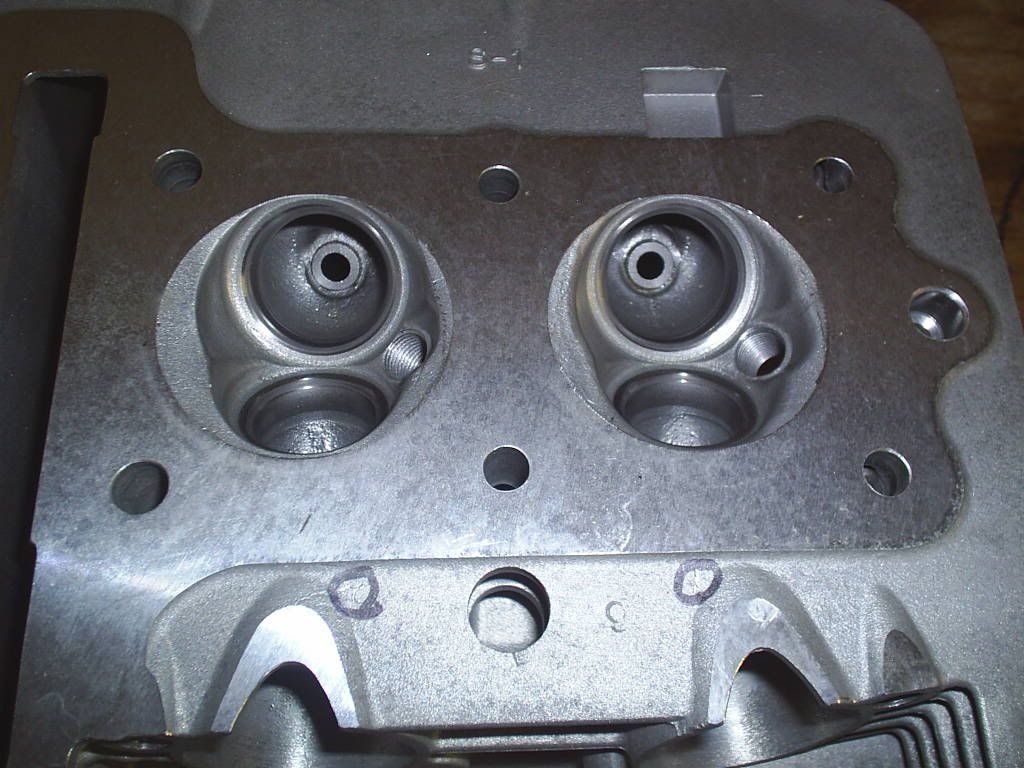

Picture below shows the shape of the combustion chambers, chamber is much smaller than the bore size and the head surface overlaps the piston flat circumference that surrounds the dome. This is the quench part of the head and piston and the reason I made my own base gasket to achieve the correct clearance between the head and piston land to achieve the best quench effect possible.If your compression ratio figure is correct, it appears that the combustion chamber design requires less static advance but more total advance for the stock 650 configuration.

The motor has really fantastic mid range punch at the present time, so it would be a shame to lose that, but I might need to go for a compromise if need be.To remedy your detonation, you still need to retard your static position by rotating the backing plate in the same direction as the rotor turns (clockwise). Try this and road test again. If you find that the mid range punch is lacking, you will need to modify the centrifugal advance mechanism, or fit the 650G advance unit.

The 650G and 650E timing specs are exactly the same (10 initial & 40 total), but the advance/retard units on them are a different part number. So don't know what going on there.Do you know the stock ignition timing specs for the 650G? I'm picking that the mechanical advance will throw out further than the 550 unit to gain the 40 degs total advance required for stock engines.

I will need to check out if I can fit the points cam from the 550 to the 650G unit and if I can then that should work ok as far as the correct advance goes. Also another option is to bend the stops outwards on the 550 unit so the bob weights can throw out further giving more advance. The bob weights on both units look the same and I would assume the same weight. Do you think 40 degrees is a lot of advance at wide open throttle.

I will do this and see what results I can come up with over the weekend probably. And report back.I suggest you retard what you've got first to get some feed back.

Thanks again.Last edited by Guest; 06-30-2011, 05:56 AM.

Comment

-

Don, IMO that's an ugly chamber design. Suzuki seem to have stepped backwards when they designed the 650E. They also reverted back to plain bearing bottom ends.Picture below shows the shape of the combustion chambers, chamber is much smaller than the bore size and the head surface overlaps the piston flat circumference that surrounds the dome. This is the quench part of the head and piston and the reason I made my own base gasket to achieve the correct clearance between the head and piston land to achieve the best quench effect possible.

40 deg total advance is huge. I have only ever seen that much advance on another poorly designed engine that the Poms (English) used as a rally engine back in the 70's. That was the Hillman Avenger piloted by Andrew Cowan. It ran 42 deg, was quite competitive but not too reliable.

Excessive amounts of spark advance are needed to combat inefficient burn off rates. Does the piston dome match the combustion chamber shape? If not and you have tightened the squish band area too much, this could be contributing towards detonation too.

I wouldn't grind off the stops on the 550 advance assy. If you can fit up the 650G one and still run the points, I'd take that option first.

Good luck with your trials this weekend.:) The road to hell is paved with good intentions......................................

GS 850GN JE 894 10.5-1 pistons, Barnett Clutch, C-W 4-1, B-B MPD Ignition, Progressive suspension, Sport Demons. Sold

GS 850GT JE 1023 11-1 pistons. Sold

GS1150ES3 stock, V&H 4-1. Sold

GS1100GD, future resto project. Sold

http://i155.photobucket.com/albums/s...s/P1000001.jpg

http://i155.photobucket.com/albums/s...s/P1000581.jpg

Comment

-

Suzuki_Don

Suzuki_Don

The plain bearing bottom end was only on the 650G, the 650E retained the roller bottom end the same as my 550 crank.Originally posted by 49er View PostSuzuki seem to have stepped backwards when they designed the 650E. They also reverted back to plain bearing bottom ends.

I did not plan to grind the stops off, just bend them out a bit so the bob weights can throw out a bit further for more advance at high revs.I wouldn't grind off the stops on the 550 advance assy.

Comment

-

Yeah, that's an option if you're careful not to overdo it. You'll get an idea of how much extra throw you're likely to need by studying the 650G assy.I did not plan to grind the stops off, just bend them out a bit so the bob weights can throw out a bit further for more advance at high revs.

Hey Psy, sorry we hijacked your post some! :) The road to hell is paved with good intentions......................................

:) The road to hell is paved with good intentions......................................

GS 850GN JE 894 10.5-1 pistons, Barnett Clutch, C-W 4-1, B-B MPD Ignition, Progressive suspension, Sport Demons. Sold

GS 850GT JE 1023 11-1 pistons. Sold

GS1150ES3 stock, V&H 4-1. Sold

GS1100GD, future resto project. Sold

http://i155.photobucket.com/albums/s...s/P1000001.jpg

http://i155.photobucket.com/albums/s...s/P1000581.jpg

Comment

-

Suzuki_Don

Suzuki_Don

Comment

-

Suzuki_Don

Suzuki_Don

I have done a comparison of the two advance/retard units after removing the 550 one from my motor. As can be seen in the next picture the F mark on the 650 unit is closer to the T mark than on the 550 unit which is what we expected to find as the 650 unit is 10° BTDC and the 550 unit is 17° BTDC.

I also found that although the 650 bob weights would not fit into the 550 cam portion of the unit which was a good fit onto the 650 shaft. The two bob weights were a different shape and had the holes drilled in different places.

The 650 bob weights had very limited movement and would not advance the cam as necessary to operate the timing correctly.

When the 550 bob weights were fitted to the 550 cam on the 650 unit because the spring holes in the plates were out by 2mm which meant the springs had to be stretch an extra 2mm and by the feel of it I didn't think the centrifugal force would be enough to throw the bob weights out against the extra pressure of the springs.

In the picture below can be seen the timing for the standard 550 advance unit. The F mark lines up with the black index mark and it can be seen where the full advance mark is in relation to the white paint mark.

This next picture shows the difference in timing with the 650 advance unit in place. There is less initial advance at idle. The odd thing is there is less total advance as well, but this 650 unit setup is supposed to give a full 40° advance above 1650 rpm whereas the 550 unit only gives 37° above 1500 rpm. So one would think the 650 total advance figure should be further away from the T (tdc) mark, but in fact the total advance for the 650 unit is closer to the T mark. Can anyone explain?

Also the cam that came off the 550 unit is about 5 or 6mm shorter than the part that came off the 650 unit and this caused other problems which I will not go into here. So I decided to dispense with the 650 unit and refit the 550 unit with all of it's original parts, springs, bob weights, etc. So I had to transfer the timing marks from the 650 unit to the 550 unit as will be seen by the centre punch marks on the unit in the pics below.

All I need to do now is dress up the points a bit. Refit the 550 advance/retard unit to the motor. Time the motor to the new timing marks on the 550 unit and after startup check it with a timing light as well as if the total advance timing mark is advancing under revs as it should. And then hopefully the pinging will be gone and I will have no flat spots when accelerating through the gears, especially in 6th out of corners.

Last edited by Guest; 07-03-2011, 03:07 PM.

Comment

-

Don, I think you will be on the money this time. But, the new specs may require you to set the engine slightly retarded of the 550 static mark. Just try it there first, and if it still pings, retard it some, until it stops pinging. You may even find it can be advanced some! Good luck.:) The road to hell is paved with good intentions......................................

GS 850GN JE 894 10.5-1 pistons, Barnett Clutch, C-W 4-1, B-B MPD Ignition, Progressive suspension, Sport Demons. Sold

GS 850GT JE 1023 11-1 pistons. Sold

GS1150ES3 stock, V&H 4-1. Sold

GS1100GD, future resto project. Sold

http://i155.photobucket.com/albums/s...s/P1000001.jpg

http://i155.photobucket.com/albums/s...s/P1000581.jpg

Comment

.png)

Comment