http://www.ebay.com/itm/221257158740...84.m1438.l2648

http://www.ebay.com/itm/221257158740...84.m1438.l2648

Announcement

Collapse

No announcement yet.

Modified Oil Pan

Collapse

X

-

Modified Oil Pan

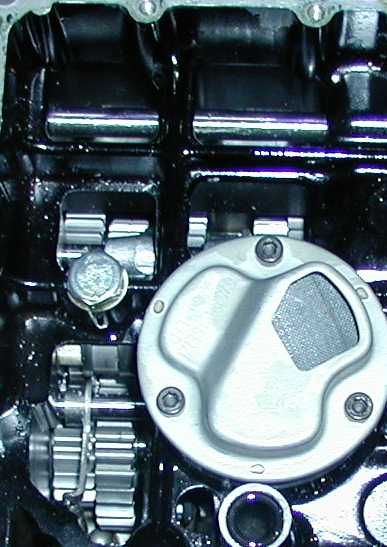

I was looking at this on Ebay and was wondering if any one had tried this or have seen it before and does it work? Looks simple enough and like it should work by relocating the pickup to a better position. http://www.ebay.com/itm/221257158740...84.m1438.l2648

sigpic 82 gs1100ez 1168 Wiseco,Web .348 Cams,Falicon Sprockets,Star Racing Ported Head,1mm o/s Stainless Valves,APE Springs,Bronze Guides,etc.APE Billet Tensioner,36CV Carbs,Stage 3 Dynojet,Plenum w/K&N filter,Trued,Welded,Balanced,Crank w/Katana rods & Billet left end, FBG backcut trans, VHR HD Clutch basket,APE nut,VHR High volume oil pump gears,1150 Oil cooler,V&H Megaphone header w/Competition baffle,Dyna S,Coils,Wires,etc.Other misc.mods.Tags: None

http://www.ebay.com/itm/221257158740...84.m1438.l2648

sigpic 82 gs1100ez 1168 Wiseco,Web .348 Cams,Falicon Sprockets,Star Racing Ported Head,1mm o/s Stainless Valves,APE Springs,Bronze Guides,etc.APE Billet Tensioner,36CV Carbs,Stage 3 Dynojet,Plenum w/K&N filter,Trued,Welded,Balanced,Crank w/Katana rods & Billet left end, FBG backcut trans, VHR HD Clutch basket,APE nut,VHR High volume oil pump gears,1150 Oil cooler,V&H Megaphone header w/Competition baffle,Dyna S,Coils,Wires,etc.Other misc.mods.Tags: None

-

Forum LongTimerBard Award Winner

GSResource Superstar

Past Site Supporter

Super Site Supporter- Oct 2003

- 17441

- Indianapolis

What bike and what are we looking at?

The picture is working fine, but the GSR Hive Mind needs some context.1983 GS850G, Cosmos Blue.

2005 KLR685, Aztec Pink - Turd II.3, the ReReReTurdening

2015 Yamaha FJ-09, Magma Red Power Corrupts...

Eat more venison.

Please provide details. The GSR Hive Mind is nearly omniscient, but not yet clairvoyant.

Celeriter equita, converteque saepe.

SUPPORT THIS SITE! DONATE TODAY!

Co-host of "The Riding Obsession" sport-touring motorcycling podcast at tro.bike!

-

geek

geek

>>Looks simple enough and like it should work by relocating the pickup to a better position.

Better how?

Never had any problems with stock on my old street bikes. I have tried a lot of different things to improve the oil system on the GS to drive a turbo on a dragbike. What you want is something that will keep the oil covering the pickup at all times, stopping, starting, turning....

Think what would happen if you put a hole in a straw between your mouth and your favorite drink.

Comment

-

stock don't care...drag bikes do...not road racing or street riding but drag racing.Originally posted by geek View Post>>Looks simple enough and like it should work by relocating the pickup to a better position.

Better how?

Never had any problems with stock on my old street bikes. I have tried a lot of different things to improve the oil system on the GS to drive a turbo on a dragbike. What you want is something that will keep the oil covering the pickup at all times, stopping, starting, turning....

Think what would happen if you put a hole in a straw between your mouth and your favorite drink.

oil ends up in the rear of the pan.

i have only used this set up with drag and turbo drag bikes with zero oiling failure's .

on a kosman chassis i used a deep sump pan with the pick up tube going into it..this was on an alky turbo bike with the motor tilted forward.

Comment

-

geek

geek

Till you hit the breaks, then all the oil goes to the front and the turbo that was at full speed ........ If you have a slow bike and a long shut down, maybe no big deal.Originally posted by blowerbike View Poststock don't care...drag bikes do...not road racing or street riding but drag racing.

oil ends up in the rear of the pan.

i have only used this set up with drag and turbo drag bikes with zero oiling failure's .

on a kosman chassis i used a deep sump pan with the pick up tube going into it..this was on an alky turbo bike with the motor tilted forward.

This thing does not even draw from the rear. The Ward pickup would be better.

Sump is the only way to go.

Comment

-

ZERO FAILURES!Originally posted by geek View PostTill you hit the breaks, then all the oil goes to the front and the turbo that was at full speed ........ If you have a slow bike and a long shut down, maybe no big deal.

This thing does not even draw from the rear. The Ward pickup would be better.

Sump is the only way to go.

not a newbie here...20+ years at this geek....

look at the picture...one is in the rear and one on the side.

now a days low 8 second bikes may not be a big deal but in 1990 not just anybody could run top gas,

food for thought............

Comment

-

geek

geek

There's no magic, you slow down too quick and that back pickup is going to be uncovered and that side one is going to do nothing even if it stays covered. Think about the straw....Originally posted by blowerbike View PostZERO FAILURES!

not a newbie here...20+ years at this geek....

look at the picture...one is in the rear and one on the side.

now a days low 8 second bikes may not be a big deal but in 1990 not just anybody could run top gas,

food for thought............

NA T/G bike, doubt there would ever be any problems. Put a sensor at the turbo inlet and log it. Then you can see what is going on.

Comment

-

i ran a 1984 mr. turbo kit on my T/G bike..rajay FF40...no problems ever.

turbo lasted till 2001 when i broke my oil pump gears at indy.

street bike takes 3.5 quarts.

i always ran 3 quarts in my drag bikes.

i just believe your over thinking this.

no sensors for me just years of doing the same thing without failure..kinda like reading the mains on a fuel engine.

Comment

-

geek

geek

Originally posted by blowerbike View Posti ran a 1984 mr. turbo kit on my T/G bike..rajay FF40...no problems ever.

turbo lasted till 2001 when i broke my oil pump gears at indy.

street bike takes 3.5 quarts.

i always ran 3 quarts in my drag bikes.

i just believe your over thinking this.

no sensors for me just years of doing the same thing without failure..kinda like reading the mains on a fuel engine.

I have replaced maybe 4 bearings and a couple of F shafts over the years from lack of oil. With the logger, easy to see why. I run normal oil height. Lots of other things that could be different between our setups.

Call it over thinking if you like, I call it paying attention to details.

The Ward pickup was much better but the sump was really the fix.

Comment

-

geek

geek

I looked but no longer have the plots of the data I took showing the oil pressure at the turbo. One thing I should mention, when I bought my Mr Turbo kit back when they were in IL, I was only running about 7 PSI. This worked with the stock pickup for many years on a street bike. Even after I put the kit on my dragbike, it was no problem with the stock pickup until I started to increase the boost.

Also, I had stuck an oiler cooler on my street bike with the turbo. When I put the kit on the dragbike, I used the cooler. Big mistake.

That said, here are some pictures of a few of my stupid ideas. (enjoy)

First attempt was the side mount, like the OP posted. That did not work so well, so I moved the two tubes to the rear as shown

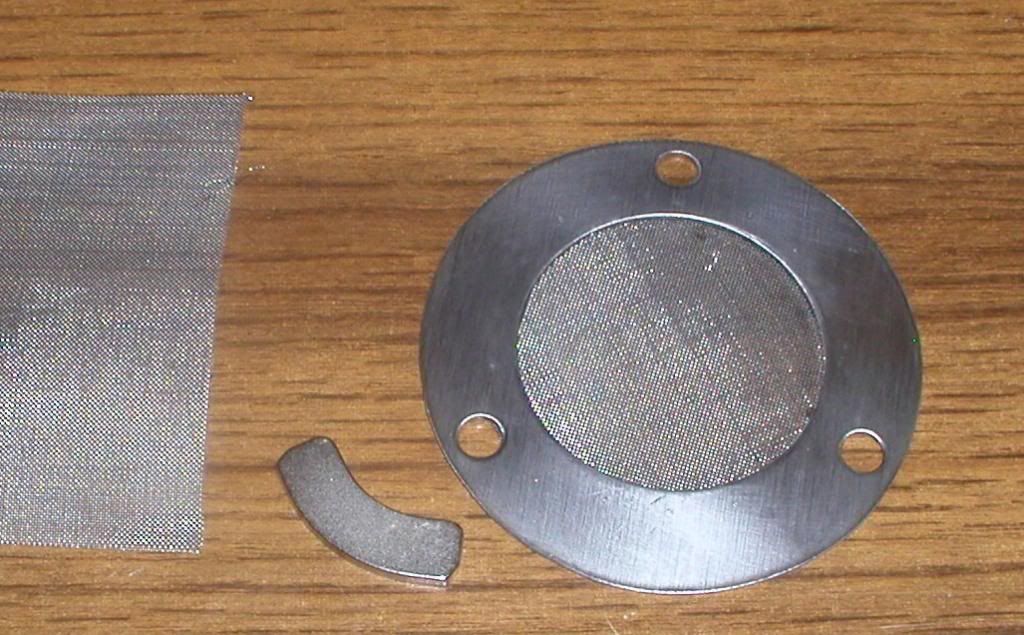

This worked very well, until I had to slow down... To try and solve this, I came up with these to try and keep some of the oil at the rear

One of the completed baffles

Those sort of helped but maybe that was me just not wanting to admit they were a waste of time..

So then I thought those hoses are too high up and I need to really get them down lower.

That pickup worked about as good as it looks.

I talked to my friends (I'm sure you know them if you ran IDBA) who ran T/G and they started telling me about the Ward pickup.

This was by far the best thing I had tried.

Next came the pipe design. I had planned to remake this at some point, but it just worked too good.

I started with a little sock over the inlet and just used a stock oil pan that I milled out and made a small well for. I later ditched the sock and welded some mesh to a plate that fits between the pickup and cases.

The high tech disk drive magnet was epoxied into place inside the large cavity where the oil feeds into it.

Oil pan with sump... Never figured this would work as the sump well is not very deep. May be over thought, but it does keep the pressure feeding the turbo pretty constant on takeoff and shutdown.

Comment

-

again...

what ever works for a person.

i had to work on motorcycles to make a living...no time to tinker.

good ideas and nice projects i see but as i said...if it is not broke well don't fix it.

i'm sure we know some of the same people and are probably both near the half century mark.

i was a dealer for a handful of the major speed parts houses.

Comment

-

I have been associated with a couple of Top Gas Turbo Suzukis over the last 20 years as engine builder and crew chief. I use the stock pick up and turn it 120 degrees. I cut off the pipe that faces to the side and cap off the hole. Then I relocate that pipe to the back so that both face the rear the way the stock location faced the front. I run the full oil capacity on the motor to the full mark on the glass. Who cases if a little extra oil slows down the crank? I make enough power to run mid 7's and only need to run 8.20. After experiencing the high volume gears breaking teeth off early on, I went back to stock oil pump gears. I have had zero oil related failures or turbo failures since. Still running the old school rajay FF40 with a super B and a Mr. Turbo kit. Dar

Comment

-

geek

geek

When I started to use a logger, I started making choices based on data rather than feelings. Just another tool is all.

Good luck finding parts if those Rajays ever die.

I have never broke the stock 750 pump gears. I still have the same set running on the dragbike that were on my street bike back in the early 80s. Have seen the tabs get knocked off before for various reasons...

7.50s is impressive. Any video of it? I met a guy at Norwalk who ran high 7's with an old draw thru, no nitrous. It was a chassis bike. I never asked the total weight. He said he would run mid 7's with the nitrous. I can believe it.I make enough power to run mid 7's and only need to run 8.20.

My old converted frame (Jack Daniels old bike from IDBA) draw thru ran a best of 8.14 without nitrous with about 27 PSI (caught some wind). It's a heavy combo. To years ago, I added more weight to the frame and bars and pulled more timing and bike ran 7.8s with about 20 PSI.

Comment

-

while we are chit chatting about opinions and what is better than whoever...

F flow parts are being bought and sold.

i run an E flow on my car...plenty of used and NOS parts around for it and cheap at times.

F flow is a little different but the parts are still out there if you look.

of course the shaft being the hard to come by item...but not impossible.

i have plenty of carbon seals

Comment

.png)

Comment