So, one pair of piston rings:

And one left piston that needs some cleaning:

The right piston is pretty much in the same shape.

So, rings off, and I kept them in the right order top to bottom to ensure I get the new ones on the right way:

So, after lots of scraping off carbon, cleaning with kero, more scraping off carbon, they looked like this:

Basically I ran out of time and patience last night to finish getting the carbon off them. I'm not trying to make them perfect, but I'm trying to get most of it off without scoring the surface.

So, now on to tonight's work, and unfortunately I just got stuck in and didn't actually take any progress pic's, just some at the end.

Basically, I finished getting as much carbon off as I could, then I removed the remaining circlip off each piston and gave them a final going over with kero to make sure they were all clean.

Then I got the rings on, and if you're going to do this at some point, here's a tip. The image in the Clymer manual seems to indicate the rings are a different shape for the top and middle, but they both were identical shapes in the packet. The difference I found is that one has what looks like a chrome ring around the very outside, whereas the other doesn't. When I compared this with the old rings, the one with chrome was on top, so that's what I stuck with. It was also really hard to make out the "R" on the rings with the chrome strip, whereas it was plain as day on the other one.

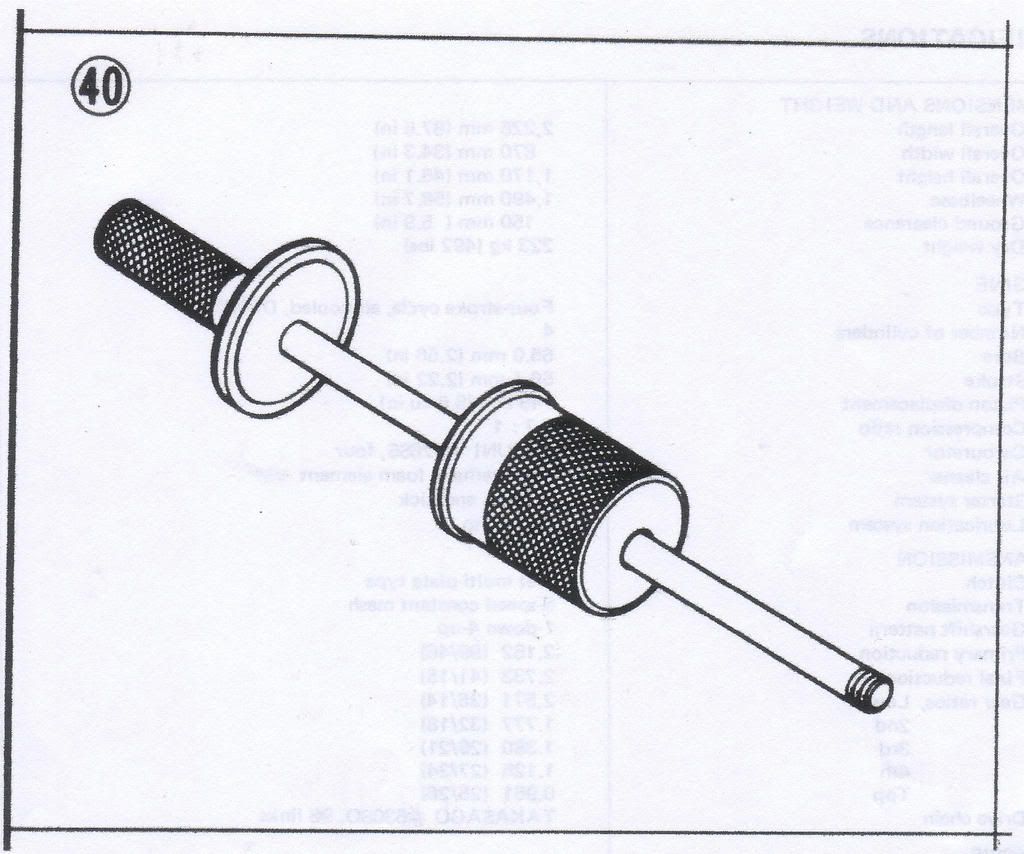

Anyway, so I got a new circlip on the inside side of both pistons, put some engine oil on the rod, piston, and piston pin.

Popped the pistons on and slide the pin home, which required very gentle tapping with a rubber headed mallet and it was nice and easy.

Then I installed the outside circlips and the pistons were all done.

If you read the tip in the Clymer manual for installing the circlips, it makes it much easier. I tried first off with long nose pliers, but was driving myself round the twist trying it that way. I found the Clymer way of pressing it in with your fingers, then I was able to use a very narrow flat head screwdriver to lever the other open end of the circlip into the slot and then slide it all home quite easily.

That probably won't make sense but it's the best I can describe it...

Anyways, so both pistons installed, and note that as I said the pistons aren't perfectly clean, but as good as I could get them without scoring the surface:

.png)

Comment