Larry said:

Announcement

Collapse

No announcement yet.

De-stinking Penelope

Collapse

X

-

Guest repliedI shall quote a famous painter from these realms, when I had the same quandary;

Guest repliedI shall quote a famous painter from these realms, when I had the same quandary;

Larry said:

Thats all your honour, the prosecution rests.Aw c'mon, Flyboy, you know you'll never be able to surround that engine with all newly painted parts w/o also painting the entire engine..

-

I have done a lot of research and tried a few recommended CLEAR-COAT products (applied as per the manufacturers specs) but I am yet to find a product that will keep the aluminium from corroding or that will not "yellow" over time. I'm done using clear-coat on the alu bits on these bikes, especially on the parts that go through the heat/cold cycles...Originally posted by rustybronco View PostCould almost clear the lower engine case as it sits! Decisions, decisions.

Hope this helps with your decision and doesn't confuse you more

Leave a comment:

-

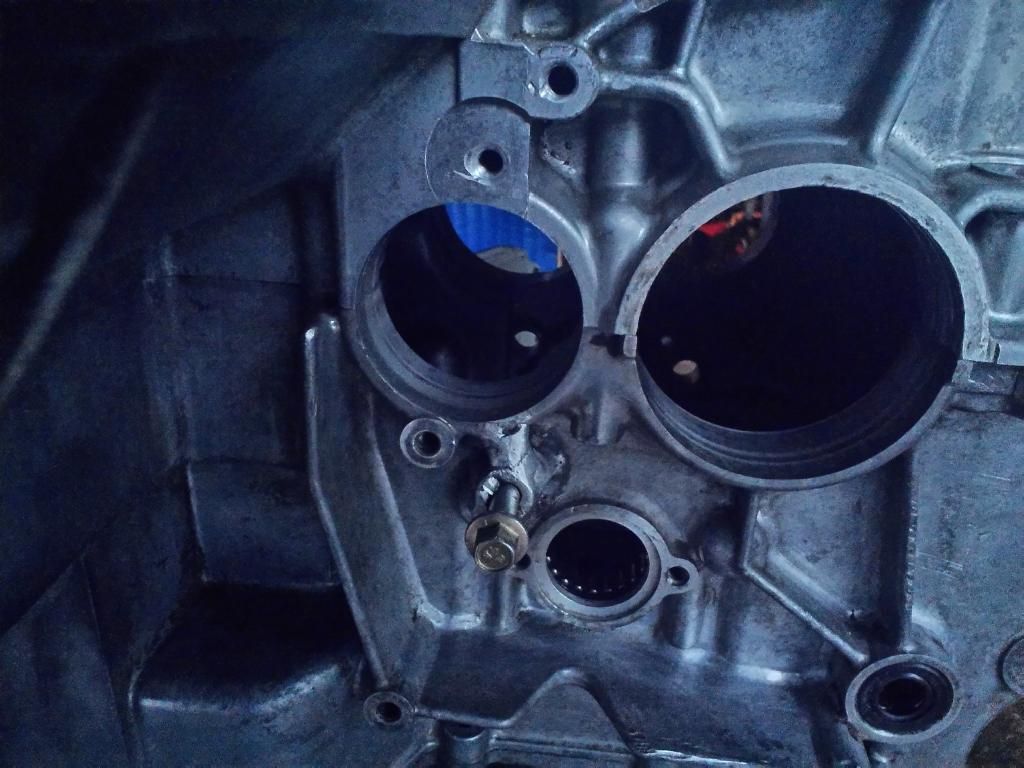

Hit the cases and valve cover with prep and etch. One of its uses is to etch aluminum for paint. I need to pick up a few more detailing brushes tomorrow to remove what's left of the corrosion then they'll be ready to paint. Could almost clear the lower engine case as it sits! Decisions, decisions.

Last edited by rustybronco; 08-17-2014, 09:08 PM.

Last edited by rustybronco; 08-17-2014, 09:08 PM.

Leave a comment:

-

-

Personally if it doesnt interfere with the cover in any way I would leave it. Nice and beefy in that areas a good thing.

Leave a comment:

-

I've given that idea more than just a fleeting thought or two.

One of the shift rail pockets has about a mm of melted aluminum from the heat of being welded. I need to remove it and I mght touch up the welds at the same time. I don't want to weaken the weld by removing too much material but the desire to neaten things up a bit is overwhelming.

Leave a comment:

-

"Something" tells me you're going to take Dremel and smooth out those welds...

Leave a comment:

-

-

Then keep watching this space.

The welder called saying the lower case is ready to be picked up and I already have the engine paint.

Leave a comment:

-

Guest repliedYahooooo, watching with interest.

Guest repliedYahooooo, watching with interest.

I also prefer a blow in system to prevent dust ingress, built a 6m X 4m booth for a budy of mine a few weeks back, and rigged it for positive pressure in the booth as he has a fiberglass works and the place is filled with fine dust that gets in everywhere.

Leave a comment:

-

The reason I'm blowing air into the booth is to keep air infiltration to a minimum. The way I figure, if I pressurize the enclosure, filtered air will escape the cracks rather than the other way around.

Currently the plan is to shoot the engine bits first then work my way into the body pieces and all the semi-gloss components. I'll leave the aluminum components that require clear until last. Need to figure out what to use to buff them after sanding in the mean time.

Eastwood products for the engine and the aluminum components.

Leave a comment:

-

Blow-in design for lack of explosion proof fan Dale? Hope you don't blow dust in. I'm sure it will be fine.

Can't wait for some action shots! Engine first? Eastwood engine paint right?

Leave a comment:

.png)

Leave a comment: