Announcement

Collapse

No announcement yet.

'81 GS550 Cafe Build

Collapse

X

-

mash35231

mash35231

D-Mac, I'm rebuilding a 82 550L and I really like the Dime City speedo and tach that you are using. Which DC speedo matches up to the factory speedo cable and what is the tach ratio?

-

D-Mac

D-Mac

Here's The good news (LOL). This re-rebuild thread is NOWHERE NEAR OVER. That's right folks, I'm about to take you into new and exotic places......into the only place we haven't been on this build yet.......

Into the bottom end.

Yup. And this leads me to the bad news.....the really, really bad news.

Let's back-up a bit.

I've been thinking a lot about the problems I've been having. I kept coming back to carbs and ignition timing because both were logical. But then I started wondering what else could cause the timing to be off badly.....cam timing....maybe an electrical fault. Maybe. Then I remembered that the bike seemed to have the same problem (popping through carbs) when I first bought it, which narrows things down a lot if the cause now is the same. What HASN'T changed since then? Hmmm....

I woke up today thinking that maybe the ignition timing appears to be "off" because the pistons aren't hitting TDC at the same time. I used a dial indicator to check the piston position in cylinder #4 compared with the TDC mark. It was perfect. But when I checked cylinder #1 (which should hit TDC at the same point as #4) it was off - way off. The piston actually reaches it's highest point about 15 degrees early. Yikes!

Diagnosis? Twisted crankshaft. I'm thinking it might have resulted from hydrolock (recall that the original petcock on the bike was faulty and drained freely at all times). I caught the overflowing carbs before I started the bike, but anyone want to bet a previous owner didn't?

Soooo....now my plan of action is:

-Verify my results.

-Remove the crankshaft from my spare parts engine (with all of the work that will entail.....just getting the side covers off of that bike will be "fun")

-Main bike: Drain oil, disconnect plugs from the engine, unbolt and pull the engine from the bike, and split the cases to pull the crankshaft. Obviously, I'll swap out the various seals and check over the transmission and clutch plates/springs at the same time. Everything will get a good cleaning too. I might even end up having to re-paint the bottom end again.

Questions:

(1) I should be able to just keep the rotor on the crank and swap rotors at the same time I swap cranks, right? (maybe a good idea anyway since the one currently on my bike is chipped a little).

(2) I'll have to pull the valve cover+tensioner+at least the exhaust camshaft to get enough slack to free the crank from the cam chain on the bottom end, right?

(3) I can avoid having to pull the top end completely off my bike, right? I don't recall anything on the top-end (other than needing to free up the cam chain, above) that would require me to pull the head or cylinder block. Basically, I just don't want to risk needing another new head gasket! Related to this, I should be able to pull out the pistons from below to swap them onto the new crank, correct? (It's actually the crank they originally came from since the top-end of my main bike came from my parts bike).

Anything else to consider?

Redneck Rocket indeed.

Comment

-

It's a really good thing we all know you're talking about a motorcycle engine here.Originally posted by D-Mac View PostThat's right folks, I'm about to take you into new and exotic places......into the only place we haven't been on this build yet.......

Into the bottom end.

Ouch!I woke up today thinking that maybe the ignition timing appears to be "off" because the pistons aren't hitting TDC at the same time. I used a dial indicator to check the piston position in cylinder #4 compared with the TDC mark. It was perfect. But when I checked cylinder #1 (which should hit TDC at the same point as #4) it was off - way off. The piston actually reaches it's highest point about 15 degrees early. Yikes!

From what I understand, hydrolocking will generally only damage an engine at speed (e.g., by suddenly sucking in a large amount of water). The starter motor doesn't have enough power to damage an engine with a cylinder full of gas. It just won't turn over. But at this point, it really doesn't matter how it happened as much as how to fix it...Diagnosis? Twisted crankshaft. I'm thinking it might have resulted from hydrolock (recall that the original petcock on the bike was faulty and drained freely at all times). I caught the overflowing carbs before I started the bike, but anyone want to bet a previous owner didn't?

I'm a newbie to this stuff, but I would think that if there was enough force to twist the crankshaft, then the connecting rods and bearings should be suspect too. You'll want to measure everything against the repair manual specs as you put it back together.Anything else to consider?

Comment

-

This is not true.Originally posted by eil View PostFrom what I understand, hydrolocking will generally only damage an engine at speed (e.g., by suddenly sucking in a large amount of water). The starter motor doesn't have enough power to damage an engine with a cylinder full of gas. It just won't turn over. But at this point, it really doesn't matter how it happened as much as how to fix it...

It can only happen when there is time for the cylinder to fill with liquid. Hit the starter, something bends or breaks.

No way an entire cylinder can fill with any liquid when the engine is running, not even close.

Comment

-

D-Mac

D-Mac -

D-Mac

D-Mac

I will check. I have the ratios and part numbers written down at home (I found them through a search on here).Originally posted by mash35231 View PostD-Mac, I'm rebuilding a 82 550L and I really like the Dime City speedo and tach that you are using. Which DC speedo matches up to the factory speedo cable and what is the tach ratio?

Comment

-

sorry to hear about your bad news but i think the good news is that you should be able to proceed with the crank swap as you intend (your points 1) to 3) in your post above)

i would however at the same time want to make sure that the crank casing is internally all as it should be so when you drop the new crank shaft in it works as it shouldGS850GT

Comment

-

JvZ

JvZ

Very impressive build D-MAC, I have just started a very similar build on a 1982 GS550e. Just got it iin November and been tinkering a bit.. I must say that You have amazing tenacity, and have produced an amazing result. A real inspiration.

Comment

-

D-Mac

D-Mac

WellÖ..as I take about 2000 steps backward, I guess I do have SOME progress to report.

You might recall that I bought a parts engine a long time ago, and used the top-end for the rebuild. So I still have the bottom-end of that junker.

PARTS ENGINE ADVENTURE:

I hauled my parts engine back into the shop yesterday with a little help from my son. Itís still sitting in its frame in this pic. Note the WOODEN inner cover. WTF. I think this bike is even more ďredneckĒ than the Redneck Rocket!! The frame of this thing has been haphazardly been rattle-canned a few times too.

After wrestling whatís left of this engine from the frame, we managed to get it into my engine stand, drained the oil, and pulled the filter.

Then I spent a little while today removing the pre-stripped screws on the side covers. Damn Iím getting good at this. I had to Dremel slots into about 10 of them in order to get a good-enough grip with my manual impact driver to force Ďem loose. They were on TIGHT.

Once the covers were off, I removed the counter-sprocket (loose already Ė just like the one on my main engine (!)) and then I pulled the locking plate on the left side. Turning to the right-side, I tackled the clutch plates + basket. A few pics of the right-side process:

Clutch basket. I will check the plates and springs on both bikes and see whatís still good.

Below Iím shown pulling out the various rods that actuate the clutch. The OEM long rod can only be removed from this side, but the one in my Main bike is actually a bunch of shorter rods that donít look stock and come out of both sides (!) Iíll likely use this assembly (stock) in the Main bike when I put it back together. You can also see the 32mm clutch hub nut in this photo.

Iíve wrestled with too many clutch hub nuts in my life. While Iím a big fan of using a holder tool (homemade or otherwise) to torque them back on correctly, thereís only one way to remove them in my opinionÖÖ. So off to a parts store for a 32mm impact socket and to Harbor Freight for a cheap, but highly rated, impact driver.

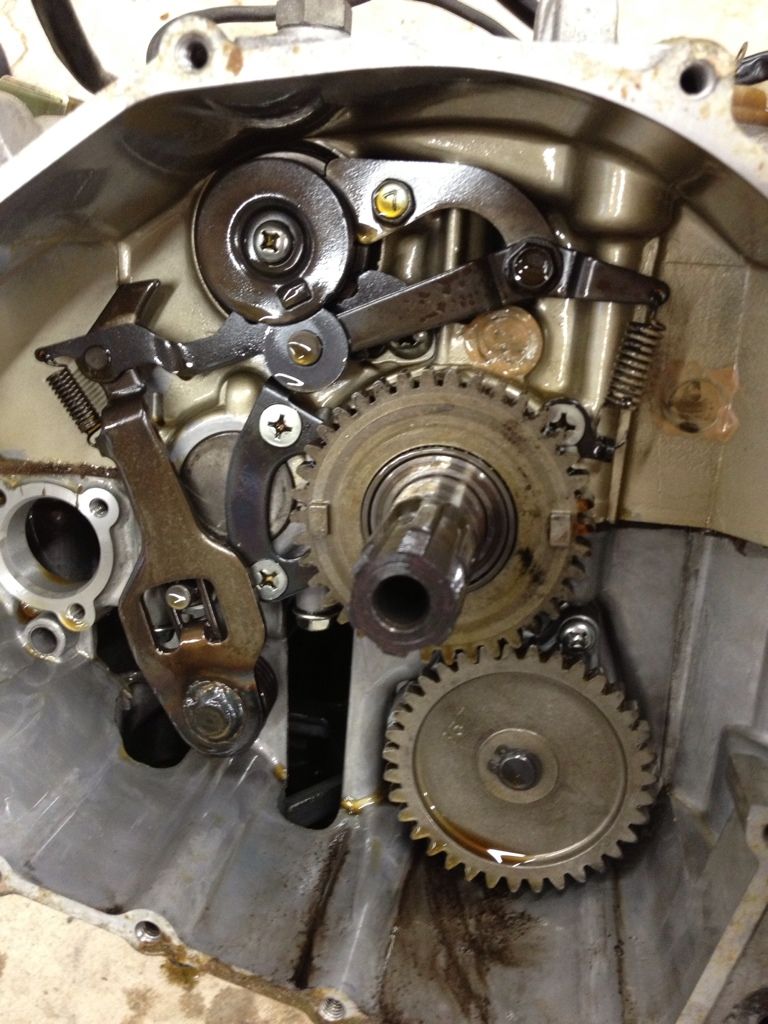

The nut came off easily. Sweet. Iíll either fab or spend a few bucks on a clutch holder for reassembly when I get to that point.

After removing the basket, a bunch of washers, various needle bearings, spacers, sprockets, more bearings, etc. etc. etc. I reached this point (below). Later this week I will pull the shift mechanism and start removing the >30 bolts holding the cases together. Iím a little worried at the rusty, corroded, and cheap quality of the case fasteners. I have a feeling I might end up having to drill them outÖ..hopefully only on this bike. Iíd like to keep both sets of cases in good shape.

Iím not going to use the mechanical advancer on this parts bike. The one on my Main bike is much cleaner. Note all the rust in the background on what looks to be the metal part of a crank sealÖ..I wonder how hard that one is to replace because it looks awful.

A friend just got back from Haiti and brought me this. Perfect timing! I need a drinkÖ..

Comment

-

D-Mac

D-Mac

A quick look at the parts fiche shows that the crank seal shown above swaps easily enough and should be replaced anyway. That's a bit of good news.

Comment

-

JvZ

JvZ

Originally posted by Sci85 View PostD-Mac, use this tool found in my thread I stole from Flyboy. Works like a champ to get the lower race out.

http://www.thegsresources.com/_forum...=185189&page=4

Sci85

I might be missing something here but I don't see the tool, could you please redirect or spell it out to me because I am wrestling with that issue at the moment and all help is appreciated!

Comment

-

D-Mac

D-Mac

You might want to PM Sci85.Originally posted by JvZ View PostI might be missing something here but I don't see the tool, could you please redirect or spell it out to me because I am wrestling with that issue at the moment and all help is appreciated!

I think you're referring to removing the lower steering head bearing race? If so, I didn't end up buying any tools to do the job. I welded a bead around the inside of the race. Old trick. The heat and weld causes the race to shrink. It'll fall right out! (If it doesn't, the weld provides a nice bump to tap it out from above). Just make sure you don't weld the race to the steering head by mistake! I have a pic of it somewhere in this thread. Any welding shop can do it in 5 minutes if you don't have a setup.

I believe the tool is some sort of pipe with slots cut in it that will "pop" out around the race if you put it down the head. Grabs the edges of the race and allows you to pound it out from above. Try MotionPro. ?

Comment

-

JvZ

JvZ

Yip, I think I'm going to give this a go. I just bought a welder for this project so it may as well get some use! Thanks guys!Originally posted by D-Mac View PostYou might want to PM Sci85.

I think you're referring to removing the lower steering head bearing race? If so, I didn't end up buying any tools to do the job. I welded a bead around the inside of the race. Old trick. ?

Comment

.png)

Comment