Announcement

Collapse

No announcement yet.

'81 GS550 Cafe Build

Collapse

X

-

Hone101

Hone101 -

D-Mac

D-Mac

I bought it from Dime City Cycles. http://www.dimecitycycles.com/vintag...-roadster.htmlOriginally posted by Hone101 View PostWhere is that seat from? I like it.

It's made by Roccity (if you go to their website there is a pic of a GS with one).

Roccity shipped it to Dime City instead of sending it to me, so that was the reason for the delay (they didn't realize the error until I checked in with them a second time).

Dime City has a video on the web showing how you can build your own for about $50. I will try that with my next project.

Comment

-

D-Mac

D-Mac

Last Sunday I picked up a parts engine for my project. It ended up having one broken exhaust stud (owner said it had none), but that’s still a heck of a lot better than the five broken studs on my bike! Not bad for $80. The engine was still in the frame (not titled, so basically useless), but the ignitor box, full harness, and other tasty bits are still attached to the frame.

“parts” engine.

So much for the perfect head. At least this broken bolt is accessible.

The plan: Keep my “main” engine in one piece for now (the one sitting on a bench in my lab) until I clean and paint the bottom end. Then I’ll remove the top end and replace it with the cylinder/head/valve cover from the parts bike (swapping out various internal components as needed – assuming that the pistons and cylinders match of course).

Parts bike:

With my plan in mind, I immediately tore into the “parts” engine and removed the valve cover, head, and cylinder. It was fun to finally get a look at this stuff. I checked the valves for the hell of it and discovered that ALL of the intakes and one exhaust were waaaaay too tight (at “0”). Not good. In fact, one intake cam has a small piece missing from it (shown below). I’ll probably toss it and use the one from my “main” engine – assuming it’s in better condition of course.

Intake cam with a chip in it.

I see lots of gasket scraping in my future!

The head was really attached to the cylinder. My garage temperature is 3F, so it took a little heat and some firm tapping to break it loose.

Finally, the head is coming loose.

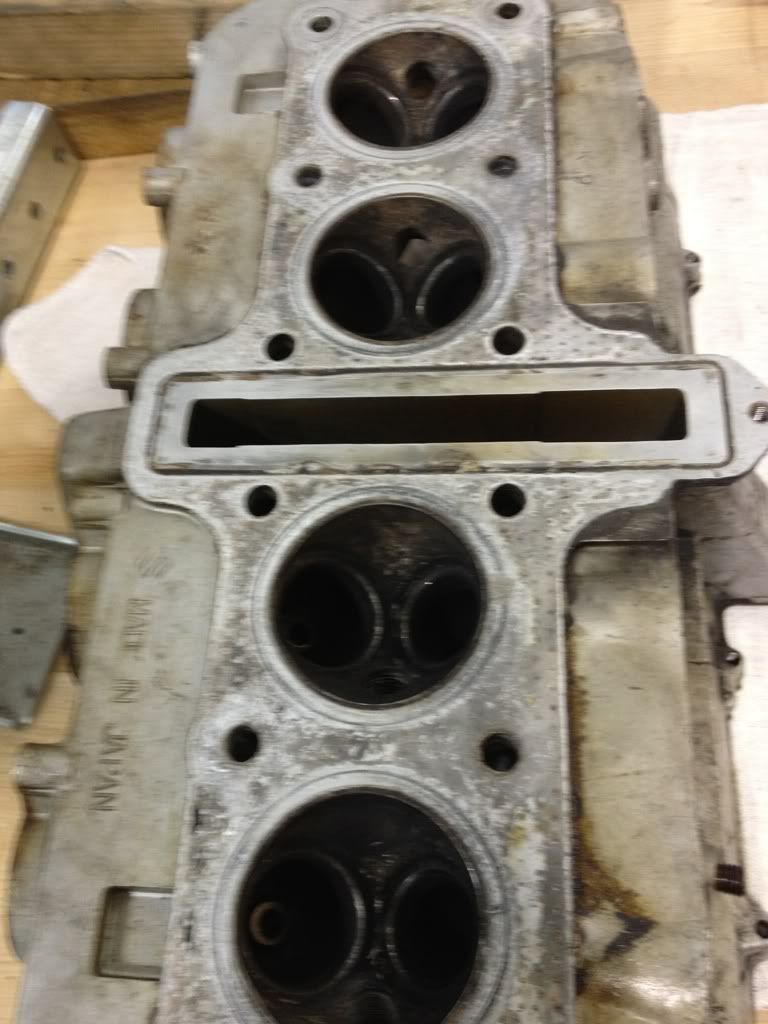

Here is the head. One exhaust valve (not shown) looks funny – like it might be burned or something. I’m going to check to see if they’re leaking first. Then I’ll pull the valves (probably with the homemade tool or possibly the “shock” removal technique) and measure them. Seals will be replaced for sure. Hopefully the guides are ok, but I’ll check them as well.

Of course I managed to mix up the buckets/shims when I flipped over the head to remove the carb boots. Oh well, I’ll be swapping intake camshafts anyway so I’ll just sort it all out later.

Pistons. Cylinder has since been removed.

Pistons look ok. I’ll have a better look once I clean the area and get the clips/pins out. Clips and rings will be replaced, and assuming the cylinder and piston-wall clearance are ok (I still need to buy a bore gauge) I’ll just re-hone the cylinders and replace the rings/clips. If things aren’t so good, I’ll check the “main” engine before I contemplate a re-bore on this one. One cylinder looks a little less than perfect, so we’ll see how it measures.

----

Having a blast?

I’m ready to repaint the valve cover and cylinder from the “parts” bike, and the carb bodies look pretty rough, so I figured I’d look into soda blasting. Harbor Freight had their 40lb soda blaster advertised for more than half-off this week, so I went to the nearest store to check it out. My rule for HF is that I’ll buy their stuff when all of the following apply: (a)reviews are good, (b)the tool won’t kill me if (when) it breaks, (c) the tool won’t be used more often than monthly, and (d) the tool is comparable in quality to alternatives that cost more than 100% more. Arriving at the store I noticed that their blasting cabinet was also extra cheap too, and even cheaper with their “insider club” price (costs $30 to join the stupid “club”, but the cabinet was an additional $35 off with a membership and I got a $10 gift card I could use immediately as well, so I went for it). Anyway, I walked away with the blasting cabinet for under $80 and the blaster for under $140 (including the extended warranty on them). Not much risk. The cabinet is actually pretty nice, and it only needs a light to make it functional. My compressor will have trouble running the blaster for very long, but I think I’ll be ok for short bursts. I put everything in my basement (too noisy and messy for my office). I’ll post pics as things go along.

Hmmmm. Baking soda. Should I blast parts with it OR buy 20 gallons of vinegar and make the biggest “volcano” of all time!?

Cabinet.

Set up.

Comment

-

Nice. Wish I had the funds for all those cool tools. Maybe on one of my trips to MI I can lug my head with me and stop by for a beer and blasting party hehe.

Oh, and I hate to say it but I don't think that broken stud is coming out. It looks like it has decomposed enough to weld itself to the aluminum. That one is going to be a stinker.1982 GS550M Rebuilt Winter '12 - 550 to 673cc engine conversion.

1989 Kawasaki ZX-7 Ninja

2016 Ducati Scrambler Full Throttle

Comment

-

D-Mac

D-Mac

Yeah. That stud does looks bad. I haven't even attempted to remove it. There are many options to try, but at worst it'll probably need to be drilled and replaced with a solid insert or I have a connection to someone with access to EDM who could zap it out.Originally posted by Sci85 View PostNice. Wish I had the funds for all those cool tools. Maybe on one of my trips to MI I can lug my head with me and stop by for a beer and blasting party hehe.

Oh, and I hate to say it but I don't think that broken stud is coming out. It looks like it has decomposed enough to weld itself to the aluminum. That one is going to be a stinker.

Comment

-

D-Mac

D-Mac

Today was pretty productive. Rather than work at home, I decided to drive in to the shop where I’m taking my motorcycle service courses. They have lots of tools I don’t own and guys who know a lot more than I do.

I started with some engine work – all on my “parts engine” since I have the head/cylinder removed.

After hitting my broken exhaust bolt with some PB blaster (more on that later), I removed the valves from the head. The guys at the shop thought the valves looked really good, but since I’m planning to soda blast the head, they agreed that I should remove them first. I’d never done this before, but it’s REALLY easy with a good tool. It would be easy enough to make one myself (as many have done), but the shop has some good sets. Some pics….

Valve removal tool (parts are from two different sets).

One valve and some of its components (keepers, valve, springs, top piece).

Here’s the head with valves removed.

Some of the valves would have been open when the bike was put into storage, and those ones have some minor pitting/rust. I think I might re-cut the seats (really just lightly do them to remove any crud) and then lap them. Normally, I wouldn’t bother, but the shop has several cutting machines and I’ve been offered a chance to learn how to do it (and it’s free). On closer examination, one valve looks like it might be cracked, so that will need to be replaced. The guides will be checked (I’m pretty sure they’re fine), but the seals will be replaced before reassembly.

Next it was on to checking the cylinders. Using my trusty micrometer set and a borrowed bore gauge, the cylinders were all within spec (all measurements at least 20-ten-thousandths or more below the service limit, which is quite good). The walls are OK, although there is a little buildup above the ring lines and some minor build-up/rust from where the rings on each piston were sitting for so long. I’ll hone them, re-measure, and then decide if it’s ok. Worst-case-scenario I have another cylinder from the other engine I can use before I would have to consider a re-bore. I think it’ll be ok with just a little honing.

Next up, I tackled removing the swingarm bearings. I had tried it at home, but my drift wasn’t “beefy” enough and I had trouble getting it into position. After setting up the swingarm in a vice and applying some heat, I was able to get them to drift out quite easily. Sweet. Again, I could probably have left them alone except that I’m going to powdercoat the swingarm. The left one was in worse shape – likely from being leaned over on the sidestand and collecting more moisture over the decades.

Swingarm bearing removal setup.

Top done – bottom still in at this point.

Finally, I tackled the broken exhaust bolt sticking out of the head. My plan for the day (after repeated PB blaster and heat treatments) was as follows – in order:

(1) Vise grips to the max

(2) Weld nut or metal bar to “stud” and try to turn

(3) Cut off stop and use left hand bit on a milling machine

(4) Continue drilling with larger bits and then use the largest EZ-out possible (after drilling all the way through to the end of the bolt)

(5) EDM (if/when the EZ-out broke)

One of the shop guys gave the vise grips a shot. Then another guy tried. Neither could get enough ‘bite’ to break the “stud” loose. As one of you reported to me, this one looked pretty terrible – likely YEARS of repeated exposure and corrosion, so I wasn’t hopeful that vise grips could work.

Then I gave the grips a shot. First, I gave the stud a firm smack with a hammer (I’ve heard that can help work things loose). Then I filed the sides a little to make them squarer, and smeared on a little grinding compound for better grip. Next, I cranked the grips down as hard as I could and used every ounce of strength I have to lock them on. Then I turned it HARD. Nothing. The grips had slipped again.

Come on you #^@%@#&*@#ARGH!!

I tried one last time and then a miracle happened. The fastener MOVED! Just a tiny amount, but I saw it. As others on the GS forum have reported, there is NOTHING like the wonderful feeling of seeing one of these “studs” start to back out.

Still, I wasn’t out of the woods yet. I had a few tense moments while I thought that perhaps the stud was simply twisting off (again), but as I continued to work it slowly back and forth (with LOTS of PB Blaster) it became clear that it was really coming out. I took it very slow, and only turned it farther when it felt nice and loose. After about 30 minutes, I worked it free. I think the threads are still good too.

FREE AT LAST!!!!

Later on, I got home decided to remove the pistons from their connecting rods. It went surprisingly easy. After removing the clips (yes, I will certainly replace them), I was able to push two pins out by hand, and the other two required only the slightest push/nudge with a socket to remove.

Piston #4. All are dirty, but look good. I’ll measure them to be sure. I’ll be replacing the rings of course.

All in all it was a good day. I will likely be soda blasting and removing gaskets soon.

Comment

-

Sounds like a long but productive day...good on you. Won't be too much longer and you'll be putting everything back together.Cowboy Up or Quit. - Run Free Lou and Rest in Peace

1981 GS550T - My First

1981 GS550L - My Eldest Daughter's - Now Sold

2007 GSF1250SA Bandit - My touring bike

Sit tall in the saddle Hold your head up high

Keep your eyes fixed where the trail meets the sky and live like you ain't afraid to die

and don't be scared, just enjoy your ride - Chris Ledoux, "The Ride"

Comment

-

Redneck

Redneck

Good work on the broken bolt, things are looking good. I take it from the soda blaster set up you going to blast that whole engine clean. Might I part some words of advice which from the sounds of things you might already know. Once everything has been blasted, rinsed, rinsed again, and blown out with an air hose, take the time and a good tap and die set, and re-tap all the holes. That was my biggest grief when I put mine back together after blasting. I am a restoration-newbie and learned that the hard way. I ended up snapping a bolt off after it bound up with grit as I was putting it back in.

Keep up the good work.

Paul

Comment

-

D-Mac

D-Mac

Excellent advice. I sprung for a set of thread chasers (also called thread restorers) from SnapOn a while back. I've read that chasers are better for this kind of thing because they clean don't re-cut the threads, which can result in undercutting and loose-fitting fasteners (among other things).Originally posted by Redneck View PostGood work on the broken bolt, things are looking good. I take it from the soda blaster set up you going to blast that whole engine clean. Might I part some words of advice which from the sounds of things you might already know. Once everything has been blasted, rinsed, rinsed again, and blown out with an air hose, take the time and a good tap and die set, and re-tap all the holes. That was my biggest grief when I put mine back together after blasting. I am a restoration-newbie and learned that the hard way. I ended up snapping a bolt off after it bound up with grit as I was putting it back in.

Keep up the good work.

Paul

That said, I know lots of guys who just re-tap them and they've never had a problem. Either method would be better than trying to force fasteners back in.

Comment

-

Good Times

Good Times -

Hi Dmac, Nice progress. What pistons are those? Look like they must be fairly high compression? Ray"Nobody goes there anymore, it's too crowded" -Yogi Berra

GS Valve Shim Club http://www.thegsresources.com/_forum...d.php?t=122394

1978 GS1000EC Back home with DJ

1979 GS1000SN The new hope

1986 VFR700F2 Recycled

Comment

-

D-Mac

D-Mac

Surprisingly enough, they're stock for this model. They are more impressive in crown shape than I was expecting, although they are really small and the stroke is sooooo short on these bikes.Originally posted by Ghostgs1 View PostHi Dmac, Nice progress. What pistons are those? Look like they must be fairly high compression? Ray

The stock shape might explain why there don't seem to be any aftermarket pistons available for the 550s (there isn't much room for improvement as far as the piston design is concerned).

Comment

-

D-Mac

D-Mac

Quick thread bump.

I spent some time this afternoon cutting off and grinding down some of the various frame tabs I no longer need (ones holding on the side covers and helmet lock; I still have the ones from the battery box, air filter, and rear fender to go). It's the most time I've ever spent with an angle grinder. The results aren't perfect, but close enough (I'll sand them a little to help things along).

If you're nervous about angle grinding, DO NOT read the following article......Yikes!

Injuries resulting from the use of angle grinders are numerous. The most common sites injured are the head and face. The high speed disc of angle grinders does not respect anatomical boundaries or structures and thus the injuries produced can be disfiguring, permanently disabling or even fatal. However, aesthetically pleasing results can be achieved with thorough debridement, resection of wound edges and careful layered functional closure after reduction and fixation of facial bone injuries. A series of penetrating facial wounds associated with angle grinder use are presented and the management and prevention of these injuries discussed.

Injuries resulting from the use of angle grinders are numerous. The most common sites injured are the head and face. The high speed disc of angle grinders does not respect anatomical boundaries or structures and thus the injuries produced can be disfiguring, permanently disabling or even fatal. However, aesthetically pleasing results can be achieved with thorough debridement, resection of wound edges and careful layered functional closure after reduction and fixation of facial bone injuries. A series of penetrating facial wounds associated with angle grinder use are presented and the management and prevention of these injuries discussed.

Comment

.png)

Comment