Announcement

Collapse

No announcement yet.

Third time

Collapse

X

-

I´we been riding a few hundred kilometers now and the bike has been mostly ok.

It like motor oil. There are same cold smoking problems as before engine overhaul.

It has to be a worn piston rings, oval shaped cylinder or something else in the cylinders & pistons.

I changed the engine oil from Mobil Delvac MX 15W 40 to Motul 7100 10W 40 which reduces a lot the cold smoking problem.

When there was the big block mounted, it does not smoked so during this summer I just refill the oil.

The supercharger has made a clattering noise on idle and when not making boost.

So I ordered a new snout coupler, which I changed today.

In the sc snout has been Motul 75W 90 full synthetic gear oil, but now I refill it with Red Line 5W 30 full synthetic engine oil. Why not "real" sc snout oil. Because it´s not so easy to find.

Anyway the 5W 30 full synthetic engine oil is recommended by GM and it´s lighter than the gear oil = less heat and less power to spinning the sc.

Comment

-

I get the supercharger snout coupler and changed it. It does not help to get the clattering noise away. I have a spare supercharger which i swapped with the noisy one.

I dismantle the noisy sc and find the rotor bearing end play was too big.

I did some internet research and decided to change the bearings by myself.

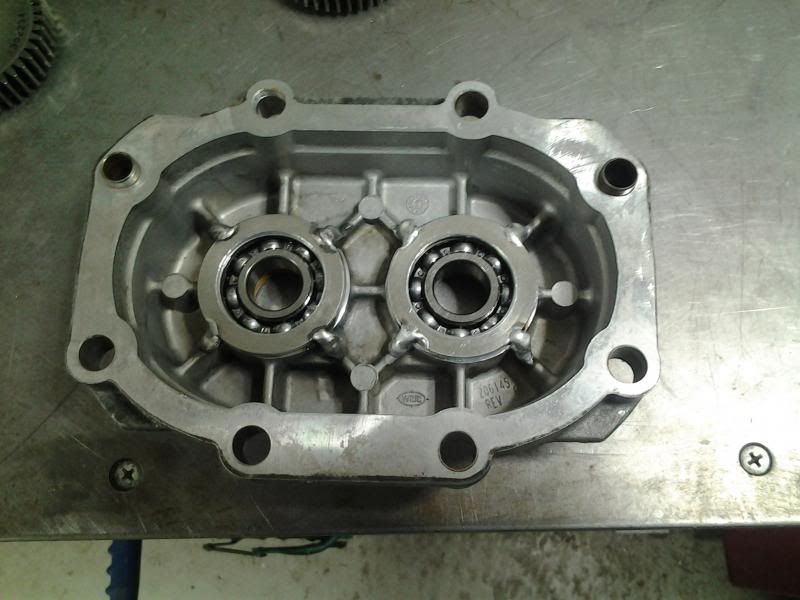

Supercharger dismantled. The snout bearings are already changed:

The rotor bearings was locked in their bores with a "rolled lip" which went broken when pressing the bearings out. I milled the lip rest away so much at the bearing sticks out about 0.2 mm. The rotor seals was in perfect condition.

ı made new rotor bearing locking washers from 2mm aluminum sheet:

New rotor bearings pressed in their bores and locking washers welded to lock the bearings:

The rotor/rotor timing is critical so I pulled a rag between the rotors when pressing the rotor gears on.

After the gears was pressed on I measured the rotor-rotor play and it was equal in both sides of the rotor lobes. The rotor endplay was only 0.06mm when it was 0.18mm with old bearings.

Next thing to do for the sc is made a smaller pulley (more boost).

Nearly finished sc:

Comment

-

Good Times

Good Times -

I need a guy like you to move in next door to me...

Personally I feel you should have left the bike the way it was and found another to do all of this to. Then you would have BOTH of the most incredible bikes I've ever seen someone build...

Just amazing work. Do you have any idea how much money you could make building these in the states????'83 GS 1100T

The Jet

sigpic

'95 GSXR 750w

The Rocket

I'm sick of all these Irish stereotypes! When I finish my beer, I'm punching someone in the face ! ! !

Comment

-

bbjumper

bbjumper

That is a miniature SC, very cool. any idea what the rpm of the rotor is at full song?

Very impressive...

Comment

-

Originally posted by bbjumper View PostThat is a miniature SC, very cool. any idea what the rpm of the rotor is at full song?

Very impressive...

Thank for your comment!

So far max rpm has been 14000. With smaller puller about 15500.

I'm going to swap the sc's when the big block is installed.

Comment

-

gearhead13

gearhead13

So, are you going back to the 1127/1150/1360 and busa pistons again? I would be interested in how it works out. Especially with boost and possible sleeve distortion, blowby.

I have had nothing but problems with mine leaking oil, from the breakthrough it seems. The oil works its way up the liners and out even though I sealed them with threebond. I found a used big block and some new sleeves on sale to run with my 80mm JE pistons.

Comment

-

Three weeks ago I get the 80mm MLS head gasket. Then I swapped the 1127/1150/1360 block back again. At the same time I inspected the cylinder head. Every one intake valve seal was leaked oil. Thats why the oil consumption was so big.Originally posted by gearhead13 View PostSo, are you going back to the 1127/1150/1360 and busa pistons again? I would be interested in how it works out. Especially with boost and possible sleeve distortion, blowby.

I have had nothing but problems with mine leaking oil, from the breakthrough it seems. The oil works its way up the liners and out even though I sealed them with threebond. I found a used big block and some new sleeves on sale to run with my 80mm JE pistons.

Strange thing, those were only about 500 miles old. Now there are other unknown brand seals and no leaks so far ( 200 miles ).

The overhauled supercharger is working fine. Boost is 0.5 bar ( 7 psi ) and what I can say, there is some kind of power in the engine

Oil leaks in the cylinder block breakthrough are sealed with Permatex Ultra Black sealer.

Areas are cleaned with acetone and then painted with sealer using small paintbrush.

Today was warm day and the cylinder temp (sensor under cam chain tensioner bolt) after highway and city riding was 130 Celsius and no leaks.

Comment

-

amxsteve

amxsteve -

My riding season with this bike ends in the end of the july. The crankshaft main bearing(s) start to made rumbling noise. I have a spare crankshaft which had also broken main bearing. I send that spare crankshaft to one of the best crankshaft specialist in Finland for reparation. I dont going to open the engine before I get that repaired crankshaft back.

So while I waiting for the crankshaft I think to minimize the risk of possible oil leaks in the cylinder head gasket area.

I´m going to block the top end oil bores in the engine block and in the cylinder head.

I made top end oiler kit which I think looks more oldskool than those billet ones.

I hope it does not vibrate broken...

First I made banjo bolt to the end of the main oil gallery. I made it from M14 bolt:

Then I made M10x1.25 threads in the rocker shaft end plugs, buy some brazed banjo fittings & brake banjo bolts, and made oil lines from 6mm hydraul pipe:

Hydraulic pipe was zink plated which needs to remove before brazing.

Half an hour in the phosphoric acid bath removs the zink plating:

All parts done:

Test fitting before painting pipes black:

Comment

-

I really appreciate your attention to detail which obviously goes part and parcel with your outstanding fabrication skills, so I kinda ponder the Top End plumbing arrangement.

It seems that the exhaust cams appear to get less pressure than the intake cams due to the supply line going to the intake first. I know at idle with my TE oiler (GS1100ED and hi po gears)you can observe oil coming out the intake cams but very little out of the exhaust. With my relatively mild bike I left well enough alone, but it would seem with your engine that would be potentially problematic.

I have not instrumented the pressure at the two ports to know the relative pressure but it sure appears that feeding the intake first reduces the flow to the exhaust much more than what your would expect.

At some point if I get bored, I could buy extended hoses and flip my TE oiler around so the exhaust gets feed first.

Since you can custom fab nearly anything, it would seem that running the feed line straight forward to feed the exhaust first and then returning to the intake would be a more robust arrangement.

Comment

-

GSX1000E

GSX1000E

I agree with posplyr for the need of increased flow to the exhaust cams. Perhaps a simple restriction in the banjo bolts for the intake cams would be the easiest solution while keeping the beauty of your work intact.

Beyond incredible build that you are sharing BTW and looking forward to more progress posts. Thanks for allowing us to follow along!

Comment

-

Yea, a restriction might work but you then get into trying to instrument the whole thing in order to determine the proper orifice size. Also the way it is designed with the banjo bolt, he would probably have to remake the banjo to drill smaller holes.Originally posted by GSX1000E View PostI agree with posplyr for the need of increased flow to the exhaust cams. Perhaps a simple restriction in the banjo bolts for the intake cams would be the easiest solution while keeping the beauty of your work intact.

Beyond incredible build that you are sharing BTW and looking forward to more progress posts. Thanks for allowing us to follow along!

And what do you wanna guess that the flow rate is a function of engine temperature or more specifically cam temperature.

Comment

-

T-connector inlet diameter is 6mm = 28.26 mm2. Hydraulic pipe inside diameter is 4mm = 12.56 mm2. The rocker shaft end plug banjo bolts have 3mm bore = 7 mm2.Originally posted by posplayr View PostI really appreciate your attention to detail which obviously goes part and parcel with your outstanding fabrication skills, so I kinda ponder the Top End plumbing arrangement.

It seems that the exhaust cams appear to get less pressure than the intake cams due to the supply line going to the intake first. I know at idle with my TE oiler (GS1100ED and hi po gears)you can observe oil coming out the intake cams but very little out of the exhaust. With my relatively mild bike I left well enough alone, but it would seem with your engine that would be potentially problematic.

I have not instrumented the pressure at the two ports to know the relative pressure but it sure appears that feeding the intake first reduces the flow to the exhaust much more than what your would expect.

At some point if I get bored, I could buy extended hoses and flip my TE oiler around so the exhaust gets feed first.

Since you can custom fab nearly anything, it would seem that running the feed line straight forward to feed the exhaust first and then returning to the intake would be a more robust arrangement.

So in theory there should be nearly same flow and pressure in both camshaft.

Comment

.png)

Comment