Announcement

Collapse

No announcement yet.

BanditRE's GS850

Collapse

X

-

BanditRE

BanditRE -

BanditRE

BanditRE

Try the pictures again..........

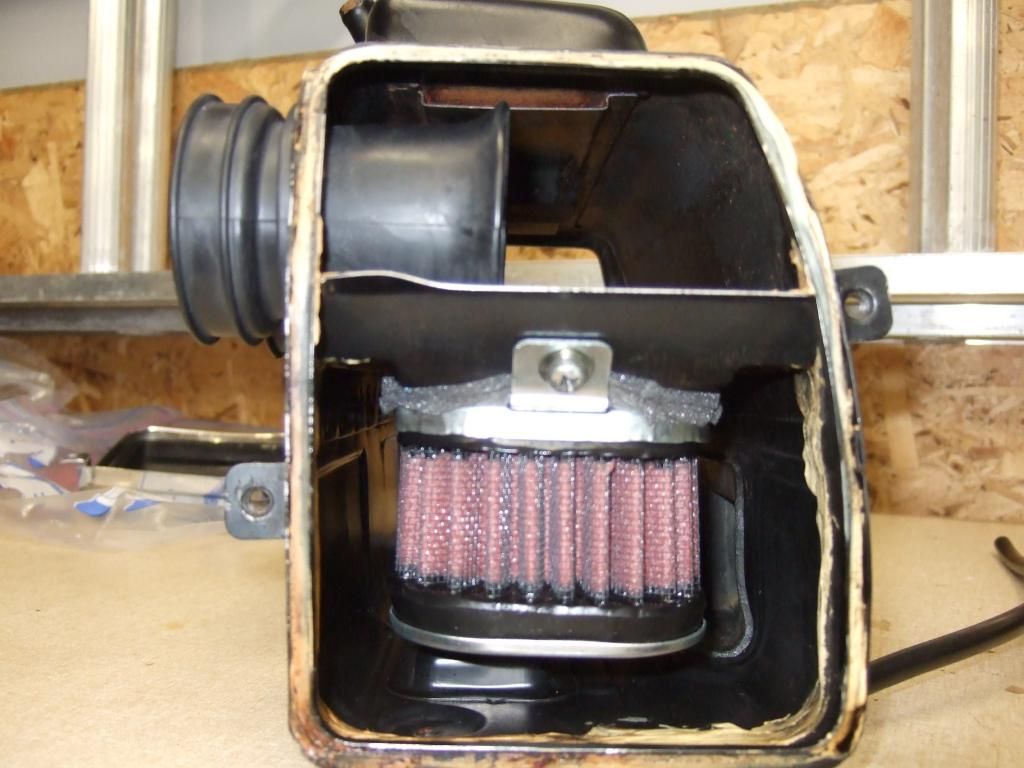

Filter cage is ok, the filter seems ok but is very dark and dirty. The rubber boots within the airbox side covers and are intact as well, but pretty old and misshapen, so I'm not sure they'll be working again or not.

I'm guessing in an attempt to start the bike, someone has sprayed starting fluid in there to get the engine moving, overdid it, backfired and suddenly you're on fire. I'm guessing an oil soaked foam filter would probably burn quite nicely.

Comment

-

I bought a K&N filter for mine. It works well and will probably outlast the rest of the bike.

Proper application of closed-cell weather stripping should seal things up okay on those end caps.

Good theory on what caused the fire, I can see that happening. (Almost would have liked to be there to watch!)

Comment

-

BanditRE

BanditRE

I was reading through old posts on filters and I think I've settled on a K&N filter too. I've had them in the past, my Enfield has one and they've worked well. I read on the forum that no re-jetting was required with the K&N filter which is nice.

Do you think I need weatherstripping if I still have the rubber seals? I cleaned up the ones that came with the bike and they're in surprisingly good shape and still supple. Covers came up nice as well with some effort.

While I was looking through the air box I checked the crankcase breather tube passages. I read an older post earlier this week where someone had mentioned that his was blocked with rust and crud and he had to clean it with a piece of wire. So I checked mine and it was totally blocked, couldn't blow through the breather fitting at all. An hour later, after scraping, filing, compressed air, carb cleaner and anything else I could think of, its now clean. I couldn't believe how much junk came out. I need to look up that post and thank the guy for mentioning it!

Comment

-

BanditRE

BanditRE

Some not so good news........ran a compression test with the engine cold as it doesn't run right now. Air box off, carbs still on. #1 was at 120, #2 was at 90, #3 was at 65 and #4 was at 110psi. Squirted some oil down #2 and #3 and the values didn't change. I think that means its most likely valves, but I need to do some homework. Bummer

Comment

-

ShadowFocus603

ShadowFocus603

Adjust your valves for sure and get it running then do the test with a warm engine and throttle wide open. Don't panic right now about the low numbers. They'll most likely come up to spec after the engine has been running awhile again.

Comment

-

BanditRE

BanditRE

Yeah, I forgot about the valves. I went back to the thread I read a few days ago and saw the "adjust valves before the test" which I didn't do. I'll finish up with the carb cleaning I started, get those put back together and then set about checking the valves. Thanks

Comment

-

BanditRE

BanditRE

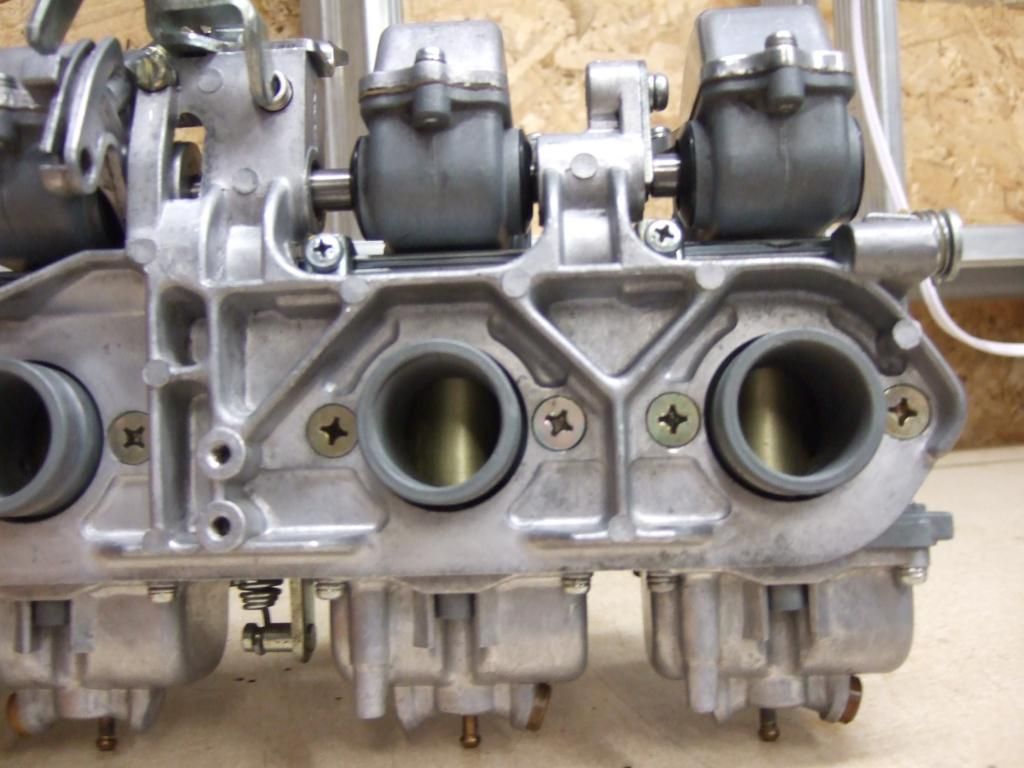

Well I got the carbs off.

Two weeks later and huffing too much solvent cleaner, they're looking a whole lot better. I'm still waiting on some parts to be able to re-install them, and I have yet to get to the valves....

Many thanks for the VM Carb Cleaning tutorial on Cliffbass' website by Paul Musser. That was very useful.

Last edited by Guest; 07-06-2014, 03:26 PM.

Last edited by Guest; 07-06-2014, 03:26 PM.

Comment

-

BanditRE

BanditRE

With the carbs freshly cleaned, I was ready to get to the valve adjustment. Things were going well, until I got to one valve cover bolt. The head of the bolt sheared right off with minimal effort. I've tried what I can think of to get the cover to budge, but it will not move. There must enough corrosion between what's left of the bolt and the valve cover to hold it firmly together. I've used as much force as I dare to without risking damage to the head or cover. Any suggestions would be appreciated. I'm about to search the site now......

Picture is from the left side. Broken bolt is immediately below the rear of the breather cover. You can see a chip on the valve cover already. I'm not sure if I did that or not. Either way, that bolt ain't moving...

Comment

-

BanditRE

BanditRE

Sheesh. Almost 6 weeks since the last post. The frozen bolt in my last post, took much time and effort to remove. It is now removed, although the original threaded hole for the bolt in the cylinder was damaged during the process. A slightly larger hole was drilled and tapped and an oversize bolt installed. All new allen head bolts used now and ALL installed using anti-seize. All that work, just to get access to check the valve clearances! So a few weeks ago, I got to check the valve clearances, #1 and #4 cylinders were within tolerance, #2 and #3 cylinders were tight on inlet and exhaust.............and those were the two with low compression when tested a few weeks ago. Of the four valves that needed new shims, three of them took the next size thinner to come within spec. The remaining valve that needed adjusting, the exhaust valve on cylinder #3, needed 3 sizes thinner, it went from a 2.60x to a 2.45. It is now gapped at 0.003", at the outside of the specified range. The tight valves on the inner cylinders had obviously contributed to the initial low compression results, but that last valve was so far off, I assume the valve has been partially open for some time. That could well cause a problem down the road.

With the new shims in place and all gaps adjusted to within the spec, the compression results were much better.

#1 cylinder = 120 psi (unchanged from previously)

#2 cylinder = 110 psi (up from 90)

#3 cylinder = 105 psi (up from 65)

#4 cylinder = 110 psi (unchanged from previously)

These readings are on a cold engine with no airbox and no carbs, as the bike is still disassembled. I'm pretty happy with that, and I'll check them again once its up and running and has a few miles under its belt.

In other news, with my work being less frantic and that rusty bolt in the valve cover finally taken of, I was able to clean up the airbox, install the new filter, seal it up and get it ready for re-installation.

Comment

-

Yay, progress! I have a boogered up bolt on my breather cover too. PO dropped the bolt on top of the cylinder in between the fins and instead of bothering to fish it out, he drove in a non-metric bolt instead, which naturally snapped when I tried to remove it. I'll get to it some day, but for now the breather cover is not leaking.

Just noticed you're pretty close by. I hail from the Ypsi/Arbor region, if you ever need a hand taking out an engine or something, let me know. I'm thinking there needs to be a regional GSR meetup soon.

Comment

-

BanditRE

BanditRE

Fasteners.........sheesh. I've had my fair share of hassles from stuck fasteners so far on this project, but the valve cover bolt was the only one that caused extended delay. I have to say it felt good to get that damn thing out, the valves adjusted and the compression back towards spec. Progress is good. Thanks for the offer of help, that's much appreciated. The engine may have to come out at some point depending on much wear the exhaust valve on #3 has seen. That old shim was likely holding the valve partially open and that could have caused some valve and seat problems. Time will tell. If I ever need help, I'll reach out to you, I'm only up M-14 and I-96 about 20-30 minutes max from Ann Arbor/Ypsi. There's always cold beer in the fridge

Comment

-

BanditRE

BanditRE

More progress on the bike. Moved on to front brakes, forks and wheel. Here are some of the front brake pictures........

Nice looking brake fluid, huh?

Frozen capiler......

Caliper apart, ready for cleaning...

Master Cylinder piston. Very nasty, a pig to disassemble, will need a complete replacement.

More lovely fluid behind the caliper piston...

Cleaned, painted and ready for the new pads, seals and lines I've ordered.....

Comment

-

BanditRE

BanditRE

Comment

.png)

Comment