Ray.

Announcement

Collapse

No announcement yet.

Scratch built GS

Collapse

X

-

Urban spaceman

Urban spaceman

The process i have used is known as Bronze welding, not sure if thats the same, but it differs from brazing in that there is virtually no capillary action. You build up a bead much like a large tig weld. The rods used contain Manganese and Tin giving excellent strength properties and are ideal for use with an inline gas fluxer - which i used. (no messy flux residues to try and clean off afterwards). I use an oxy/propane setup.

Aerial atom car chassis are built that way, Theres some really good videos on YouTube of them using the process. https://www.youtube.com/watch?v=ZlLV0P6uGDw

The joint on a frame can never allow flexing. The design of a frame and the materials used can allow flexing, and in the case of Karts, they have no suspension and run for hours on sometimes bumpy tracks - and so the tube thickness and chassis design will allow flex to absorb the bumps, otherwise - if it was rigid something would break and it wouldn't handle. The reason they are sometimes brazed is that with all that flex welds could crack whereas brazed joints will not. The bronze welded fillet is probably stiffer than a tig weld if anything as it runs further up the tube. It also doesn't embrittle the parent material as theres not much heat put into the tube. So less chance of cracking in the HAZ.

I've chosen it as it's a nice and perfectly suitable way of joining tubes, and not used much these days.

Comment

-

Yeah, I know the process, same as building the cart chassis. I just don't see it as strong as tig welding with steel filler rod. There are NO chassis for drag racing, cars or motorcycles, welded that way here in the USA so not sure if it would even be legal here. When I worked for Gary Hansen Race Cars we did use silicon bronze rod at times for tig welding roll cage mounting plates to existing floor pans. We used it on sheet metal also but that was about it, & the metal is was being welded to had to be SPOTLESS clean! Interesting though. I am waiting to see how yours runs when finished.

Ray.

Comment

-

Urban spaceman

Urban spaceman

Your probably right ray, i doubt the join itself is as strong as tig either. The biggest benefit i found is that there's pretty much no movement whatsoever in the tubes while your brazing the chassis up. It required no tweaking, or allowances for movement whatsoever.

In europe i know a few bikes are bronze welded, in the UK Bob Brooks Yellow Metal bike and my own have been running bronze welded steel and ally wheely bars for years with no problems, oh and our UK national tech inspector - his very own race bike also has an entirely bronze welded chassis.

All my racing endeavors are on my Blog and FB page, so i'll copy some of it here and we'll get to see how it works sometime next year hopefully.

Oh, and the tube is also unconventional for you folks, it's T45 not chromoly. Just to break the mold some more.

Comment

-

Urban spaceman

Urban spaceman

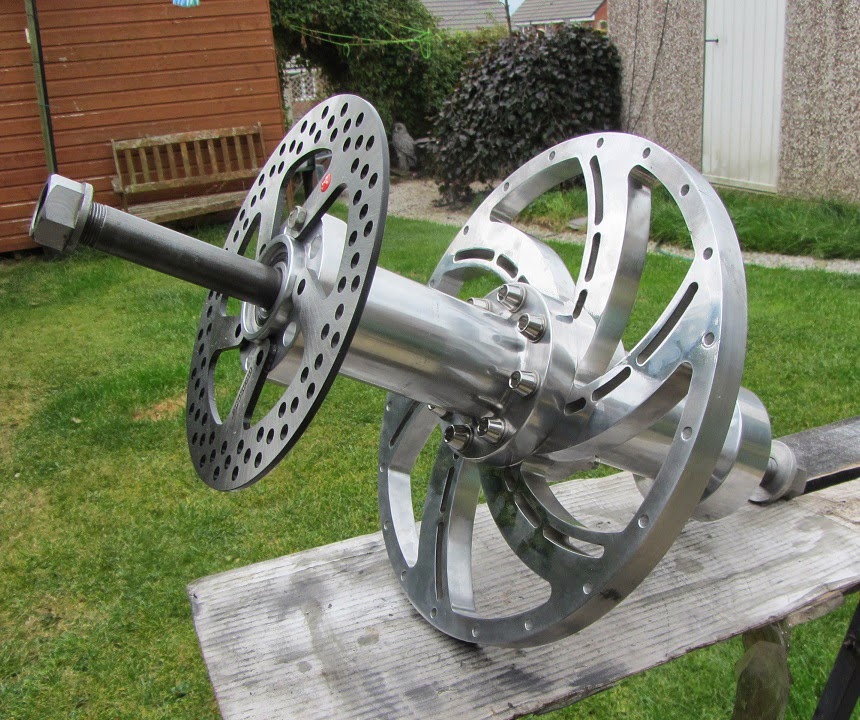

This was back in September, back wheel which is was done mostly on my lathe and with a waterjet cut center, which is under construction.....

Comment

-

Urban spaceman

Urban spaceman

And this is where it's up to as of today.

Sprocket support plate also waterjet cut and finished on the mill.

Comment

-

Urban spaceman

Urban spaceman

Yeah, you may learn exactly how NOT to build a dragbike lol.Originally posted by rapidray View PostCool! I am always open to learning new things! I look forward to seeing your pictures & experience!

Ray.

I'm no expert ray, you'll know a damn sight more than i do. I'm just having a go and enjoying doing it.

Comment

-

Urban spaceman

Urban spaceman

Some more progress. Theres more work than i anticipated .... been on the go 12 months now, but getting there

Comment

-

ShadowFocus603

ShadowFocus603 -

Forum LongTimerGSResource Superstar

Past Site Supporter

Super Site Supporter- Mar 2006

- 35896

- Torrance, CA

Looks like plain old fillet brazed to me. If you are melting the parent steel tubing during the process I can see why they might call it "welding" though. At any rate, the rear end of that frame looks killer stiff but the front looks spindly. Particularly along the top backbone. Hopefully it's just an optical illusion.

Looks like a fun project.Ed

To measure is to know.

Mikuni O-ring Kits For Sale...https://www.thegsresources.com/_foru...ts#post1703182

Top Newbie Mistakes thread...http://www.thegsresources.com/_forum...d.php?t=171846

Carb rebuild tutorial...https://gsarchive.bwringer.com/mtsac...d_Tutorial.pdf

KZ750E Rebuild Thread...http://www.thegsresources.com/_forum...0-Resurrection

Comment

-

Urban spaceman

Urban spaceman

I've no idea why it's called bronze welding and no it doesn't melt the parent material, but it clearly differs from fillet brazing as ... well theres not a smooth fillet formed and the bronze doesn't flow at all.Originally posted by Nessism View PostLooks like plain old fillet brazed to me. If you are melting the parent steel tubing during the process I can see why they might call it "welding" though. At any rate, the rear end of that frame looks killer stiff but the front looks spindly. Particularly along the top backbone. Hopefully it's just an optical illusion.

Looks like a fun project.

It's the 'engineering' term for the process though and it uses a different composition of filler rod to brazing or fillet brazing.

The front end is somewhat unimportant on a drag bike (so long as it doesn't fall off it will do the job), but that said it's still got one cross tube to go in once i've decided how big to make the fuel tank. And remember the tubes ain't 1" erw like the factory tubes it's seamless 1 1/4 T45 tube. And it's amazingly strong

Comment

-

Urban spaceman

Urban spaceman

i forgot all about this thread. The bike is now finished and has done 3 race meetings, 2 of which were rained off and one it won. It handles really good and stops easily. I hope you like it.

Currently using my old bikes engine which is 1500cc with 26/31 valve head and 40mm Lectons. The new engine will be ready for next season hopefully.

Best time so far is a 7.34 @177mph and a 1.07 60ft.

Comment

-

Forum LongTimerGSResource Superstar

Past Site Supporter

Super Site Supporter- Mar 2006

- 35896

- Torrance, CA

Wow wow wow! That thing's AWESOME! 7.34 is FAST! Got a video?

EDIT: found a little blurb about bronze welding...http://www.technologystudent.com/equip_flsh/acet6.html

Not sure the weld engineers would call it that term though.Last edited by Nessism; 11-01-2015, 05:47 PM.Ed

To measure is to know.

Mikuni O-ring Kits For Sale...https://www.thegsresources.com/_foru...ts#post1703182

Top Newbie Mistakes thread...http://www.thegsresources.com/_forum...d.php?t=171846

Carb rebuild tutorial...https://gsarchive.bwringer.com/mtsac...d_Tutorial.pdf

KZ750E Rebuild Thread...http://www.thegsresources.com/_forum...0-Resurrection

Comment

.png)

Comment