Announcement

Collapse

No announcement yet.

1981 gs750 (gs750e) Retro Racer project

Collapse

X

-

This is the mess I stitched together last summer to get the bike rideable.. Hurts my eyes to look at it

This is the new electronics box with the M-unit Blue and ignition module. I also integrated a copper ground terminal.

I'l draw some sketches to see how to best route the rest of the cables and make Weather Pack connectors for the different cable clusters.

Comment

-

Hi! Could you please elaborate a little bit more about the CNC?! Is it this: https://www.v1engineering.com/ ???

Thanks, much appreciated

Originally posted by LarsKroghStea View PostWell.. stuff always seem to happen. My father in law bought a Creality Ender 3 Pro 3D printer a while ago. He was the one who printed the "speedo converter" I designed:

IMG_20200416_223222 by Lars Krogh-Stea, on Flickr

IMG_20200416_223222 by Lars Krogh-Stea, on Flickr

I ended up with another solution, but at least I now know I have the skills to design parts that are printable

A couple of weeks ago, he handed med the 3D printer. It had become an object of annoyance to him, as he never got it to work well. He recently moved into a new house, and had decided he didn't want to use any more time on it. It is now mine, if i print some parts for him now and then. I've gotten the printer to print perfectly now (took some work), and it's an awesome tool to have at my disposal. But what do you do when you have a machine that can make parts of alomst any shape? You make another cool machine Looking for solutions, he upgraded the controlboard, and he gave me the old board with the printer. I bought 5 used stepper motors for 20$, and the rest of the parts on Ebay for about 120$. If everything goes well, I'll have a CNC-router capable of milling aluminum at the cost of about 150$ As I have access to a lathe at my dads, the ability to make cool parts for my bike should now only be limited to my own CAD-capabilities

Looking for solutions, he upgraded the controlboard, and he gave me the old board with the printer. I bought 5 used stepper motors for 20$, and the rest of the parts on Ebay for about 120$. If everything goes well, I'll have a CNC-router capable of milling aluminum at the cost of about 150$ As I have access to a lathe at my dads, the ability to make cool parts for my bike should now only be limited to my own CAD-capabilities

Heres a picture of the printer:

Here's a picture of the parts I'm printing:

And here's a picture of what the router will look like. Most People in the US use Makita or DeWalt, but I'll print a tool holder for the blue Bosch grinder I already own. It's the same power as the Makita, 27k rpm and variable speed. Should mill alu with no problem;

Lang versjon by Lars Krogh-Stea, on Flickr

Lang versjon by Lars Krogh-Stea, on Flickr

I'm really exited to add these parts to my shop, and I thought it would be cool to post about it. I'll make som updates on the bike soon Vancouver, BC

Vancouver, BC

Suzuki GS 650G '81

Comment

-

Hi! Yes it's the MPCNC (Mostly Printed CNC) from v1 Engineering. It's the new model and they have redesigned most of the parts for greater stability and accuracy. I haven't had time to assemble it yet, and probably won't before fall. When I do get it up and going, I'll post some videos from the triple clamp projectOriginally posted by Berti View PostHi! Could you please elaborate a little bit more about the CNC?! Is it this: https://www.v1engineering.com/ ???

Thanks, much appreciated

Comment

-

Thanks! Sounds great. I'm eyeballing that DIY CNC for a while. Unfortunately I don't have the appropriate space (yet). Otherwise I would have already printed it... Maybe next winterOriginally posted by LarsKroghStea View PostHi! Yes it's the MPCNC (Mostly Printed CNC) from v1 Engineering. It's the new model and they have redesigned most of the parts for greater stability and accuracy. I haven't had time to assemble it yet, and probably won't before fall. When I do get it up and going, I'll post some videos from the triple clamp project

Vancouver, BC

Vancouver, BC

Suzuki GS 650G '81

Comment

-

Awesome, keep me updated! Would be great to exchange ideas and info about making motorcycle partsOriginally posted by Berti View PostThanks! Sounds great. I'm eyeballing that DIY CNC for a while. Unfortunately I don't have the appropriate space (yet). Otherwise I would have already printed it... Maybe next winter

Comment

-

Well.. Today I'm both happy and annoyed with my self. Last summer I spent hour after hour trying to get the petcock to flow enough gas to make the bike pull at higher RPMs. I overhauled the carbs, changed fuel-filter and more. I was convinced that the only thing I had changed from when the bike ran well was the little pocket-bike fuel-tank. I heard of someone that had the same problems and found out that it was a faulty coil. These bikes seem to run quite smooth on low RPMs, even when firing on only two of the cylinders. As the spark wires are in bad condition and one of the coils seemed to have leaked, I ordered a set of green Dynas with wires.

While I waited for the Dynas I found an old clip from when I did the first test run. And what do you know.. The bike was wired up with only the bare essentials, and with spring loaded connectors. Seems like I was wrong about the fuel tank, and I decided to check the wiring. There was all sorts of tings wrong with the weather pack connector for the coils:

It's a bit hard to see, but it's supposed to be three pins in this connectors in this plug. The middle one is 12V, the two outer pins are for each coil. One of them is pushed back by the bent plastic guide-pin. This was one of the first connectors I made, and I didn't have any previous experience. I managed to get two different pins mixed up. They are almost identical, but when you use the wrong one the won't lock in place. This error made one of the coils go dead of course, and I'm pretty sure the bike will run as it should after fixing this

Pretty annoyed that I wasted countless hours, and only got one trip on the bike last summer :/ But pretty happy that I found the error. I was going install the Dyna coils, but it seemed like they needed some adapters:

I decided to just fix the connector in stead. After I put everything together, I noticed it's possible to remove the adapters from the old ones. Doesn't matter.. I wanted to test the old ones anyway. I'll change coils later

I have a lot more wires to sort out, but I'm getting the hang of it and taking the time it needs to be done correctly.

Comment

-

I also ran into an issue with the wiring of my coils....Originally posted by LarsKroghStea View PostWell.. Today I'm both happy and annoyed with my self. Last summer I spent hour after hour trying to get the petcock to flow enough gas to make the bike pull at higher RPMs. I overhauled the carbs, changed fuel-filter and more. I was convinced that the only thing I had changed from when the bike ran well was the little pocket-bike fuel-tank. I heard of someone that had the same problems and found out that it was a faulty coil. These bikes seem to run quite smooth on low RPMs, even when firing on only two of the cylinders. As the spark wires are in bad condition and one of the coils seemed to have leaked, I ordered a set of green Dynas with wires.

While I waited for the Dynas I found an old clip from when I did the first test run. And what do you know.. The bike was wired up with only the bare essentials, and with spring loaded connectors. Seems like I was wrong about the fuel tank, and I decided to check the wiring. There was all sorts of tings wrong with the weather pack connector for the coils:

It's a bit hard to see, but it's supposed to be three pins in this connectors in this plug. The middle one is 12V, the two outer pins are for each coil. One of them is pushed back by the bent plastic guide-pin. This was one of the first connectors I made, and I didn't have any previous experience. I managed to get two different pins mixed up. They are almost identical, but when you use the wrong one the won't lock in place. This error made one of the coils go dead of course, and I'm pretty sure the bike will run as it should after fixing this

Pretty annoyed that I wasted countless hours, and only got one trip on the bike last summer :/ But pretty happy that I found the error. I was going install the Dyna coils, but it seemed like they needed some adapters:

I decided to just fix the connector in stead. After I put everything together, I noticed it's possible to remove the adapters from the old ones. Doesn't matter.. I wanted to test the old ones anyway. I'll change coils later

I have a lot more wires to sort out, but I'm getting the hang of it and taking the time it needs to be done correctly.

In fact during one iteration of the bike setup, I had pulled a wire from one of the coils to an electronic tachometer.

When I reverted the bike to OEM, it would refuse to take full rpm among other running issues!

The reason was that I had "borrowed" the wire that is normally used for the fuel gauge to carry the tacho signal.

When reverting to OEM, the tacho signal went to ground through the OEM defective fuel gauge.

BTW, I'd like to buy some Dyno coils but what's your model and what cables are you using?sigpicJohn Kat

My bikes: CB 77, GS 1000 ST Cafe Racer with GSXR 1052 engine, GS 1000 ST, XR 41 Replica with GS 1085 engine,

GS 1100 SZ Katana with GS 1135 EFF engine, KTM Superduke 1290 R 2020

Comment

-

Hope you got it sorted quickly

Here's the description from the ebay ad:

2021-06-20_03-17-10 by Lars Krogh-Stea, on Flickr

2021-06-20_03-17-10 by Lars Krogh-Stea, on Flickr

Keep in mind that I haven't mounted or tested it yet, but it should be the correct parts

Comment

-

The cables come as two wires with coil connectors in both ends. You cut them to length and crimp the plug connectors yourself.Originally posted by John Kat View PostI also ran into an issue with the wiring of my coils....

In fact during one iteration of the bike setup, I had pulled a wire from one of the coils to an electronic tachometer.

When I reverted the bike to OEM, it would refuse to take full rpm among other running issues!

The reason was that I had "borrowed" the wire that is normally used for the fuel gauge to carry the tacho signal.

When reverting to OEM, the tacho signal went to ground through the OEM defective fuel gauge.

BTW, I'd like to buy some Dyno coils but what's your model and what cables are you using?

Comment

-

Hi Lars

How are things going?

On my side, I'm currently restoring a GS 1000 with a GSX 1135 engine.

I'll look through your posts but I was wondering how you solved the throttle assy on your bike?

Given that the control switches are becoming a rarity we are almost obliged to use suitable aftermarket parts that leave an issue with the throttle assy.

Motion Pro has apparently a suitable item (Motion Pro Push/Pull Throttle Assembly Kit for Mikuni Racing Carburetors | Kawasaki and Suzuki Motorcycle Parts | Z1 Enterprises) but what about 3D modelling a plastic part that would take the OEM throttle cable?

Let me know your thoughts.

Update:

I see you used a Domino throttle assy.

Is it the XM2 version?

Where did you buy it from?Last edited by John Kat; 08-30-2021, 01:39 PM.sigpicJohn Kat

My bikes: CB 77, GS 1000 ST Cafe Racer with GSXR 1052 engine, GS 1000 ST, XR 41 Replica with GS 1085 engine,

GS 1100 SZ Katana with GS 1135 EFF engine, KTM Superduke 1290 R 2020

Comment

-

Well.. I'm almost embarrassed to revive this old thread Started in 2015, and still the bike is not roadworthy (even though it was for a couple of weeks, before I started the fork swap).

Started in 2015, and still the bike is not roadworthy (even though it was for a couple of weeks, before I started the fork swap).

It got put in the back of the garage in '21 as my work in hospital leadership became too time consuming. This febrary, I descided to change my carreerpath and applied for a position as leadership advisor in stead. Maybe not the same long time carreer opportunities, but much less stress and no people to manage. Also the work itself is much more interesting.

With more spare time, I've started doing some mechanical stuff again. Changed the clutch/flywheel on a Volvo V60, which was a lot of work.. Also helped my youngest son with his Audi TT. Bought a lot of new tools, and got bitten by the garage bug again Last week I dug out the old GS from the garage and rigged a workshop in one of the sheds. Spent the evening there today, and realized how relaxing it is

Last week I dug out the old GS from the garage and rigged a workshop in one of the sheds. Spent the evening there today, and realized how relaxing it is

I promise you guys; this summer I'm going to ride the bike a lot. And now that i've made the promise, I'll have to get it done

I bought a new battery today, as the old one had gotten really old, and booted up the mo-unit. I cut most of the wires when switching out the stock fork for the 2005/6 GSXR fork, so the first I'll have to do is wire the bike up again. Then there's the brakes, clutch and throttle. I will also need to 3D-print a housing for the Motogadget mini.

Here's a motivational short of the Mo-unit booting up:

- Likes 1

Comment

-

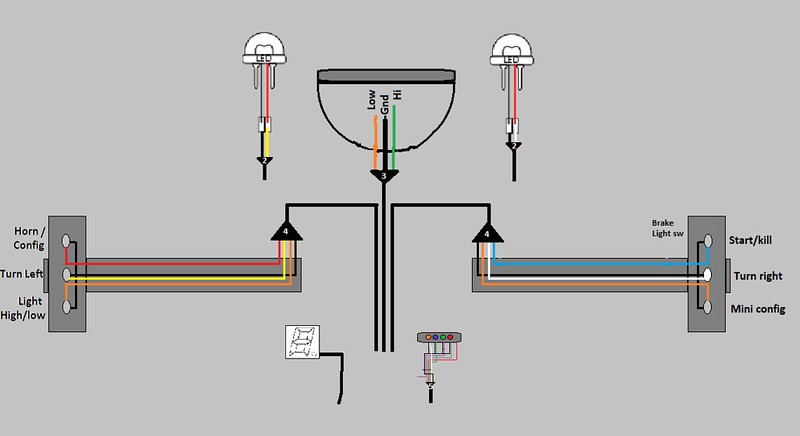

So, this is the wiring diagram for the bike:

Noisemaker_koblingsskjema by Lars Krogh-Stea, on Flickr

Noisemaker_koblingsskjema by Lars Krogh-Stea, on Flickr

First time I wired it up, I made several mistakes:- I used a lot of "velour tape" (looks like old electrical tape), because i thought it looked cool. Ended up with very a very stiff and bulky wiring loom.

- I didn't make the loom modular, which meant changing out parts resulted in the need to cut and resolder wires. I also got some advice to not rely too much on soldering, as the wires can become brittle and crack.

- I also didn't look into the original routes for the different wires. This resulted in the loom making a loop away from the frame when turning left, and getting almost too tight when turning right.

- Using nylon sleeves and heat shrink the ends. This makes for a very flexible loom, that also look good.

- Make a better plan for the layout, and put connectors between the main loom and the removable parts.

- Research better routes for the cables that connect to the fork. The wires should cross from the fork to the frame in a vertical path, rather than horizontal, to eliminate the need to compensate for the turning of the handlebars.

The solution for no.1 and 2, looks like this:

IMG_20210517_125303 by Lars Krogh-Stea, on Flickr

IMG_20210517_125303 by Lars Krogh-Stea, on Flickr

And grouping of wires looks like this:

Wiring front by Lars Krogh-Stea, on Flickr

Wiring front by Lars Krogh-Stea, on Flickr

Routing looks something like this, but I have to compensate for the clip-ons being positioned much lower:

Wire routing_1 by Lars Krogh-Stea, on Flickr

Wire routing_1 by Lars Krogh-Stea, on Flickr

Comment

.png)

Comment