Announcement

Collapse

No announcement yet.

Zagg's Project: '78 GS750E

Collapse

X

-

Zagg

Zagg

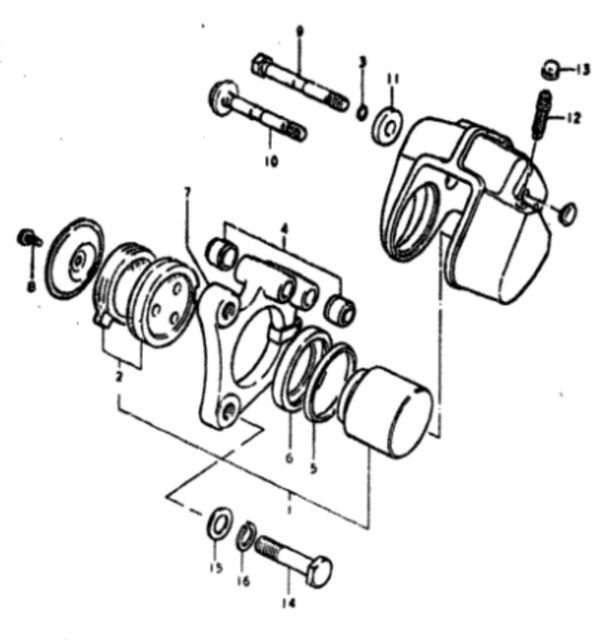

Thanks Weasel! I am sorry, I was not clear with my wording... what I meant was that I could not find a pic of my calipers after they were rebuilt and painted. Thank you for the exploded views!Originally posted by Weasel View Post

-

Zagg

Zagg -

Zagg

Zagg -

Zagg

Zagg

I do not have any pics of the bondo I used to fix the rust holes along the seems and the dents, but I had this briefly...

You could see the bondo if you looked closely. I have painted several truck and motorcycle parts before but none that mattered. This was / is my first attempt at a "good" paint job. Self etching primer on, 4-5 coats til the can ran out. All imperfections in prep work aside it wasn't all bad. I could live with it which is saying something. So I broke out the 1000 grit sandpaper to get it smoothed out AND...

Tank rolled off the sawhorse and BOOM. There was some "eye irritation" immediately following this event... Must have gotten some paint in my eyes... Anyway, a little more bondo and have it sanded down ready for a little more primer. More pics this weekend.

Comment

-

Zagg

Zagg

I was watching an interview with the owners of Blitz Moto and they were saying that they never touched the tank on their resto's. Kinda cool. I've considered picking up a tank with original paint and roll with it, but it seems like a waste of money at the moment. I can get this one good to go for $20. I am trying to stay focused on the "Road Ready" goals and leave the cool stuff for later.

-Necessary Goals for Road Ready-

Wiring

Test / Replace Original Coil

Test / Replace Original Stator

Test / Replace Controls

Battery Tray / Electronics mounting location

Brake Line Upgrade

Rebuild Rear Caliper

Rebuild Rear Master

Troubleshoot Tranny

Replace Clutch Discs

Rebuild Forks

Wheel Bearings

Tires

Chain Replacement

Comment

-

jibledso

jibledso

Hello! Great thread, it's helping me with my 77' 750 project. If you get the bike running before I get mine I'd love to know what your carb set up will be. I'm running a 4-1, not sure the make, and a K&N stock replacement, so similar to yours.

Good luck!

Comment

-

Zagg

Zagg

Awesome! Good luck! I have had mine for a while now. Seemed daunting at first, but focus on one part of the bike makes it doable. The money tree is my biggest obstacle followed by time. I have a 4-1 Vance and Hines. I am ditching the air box for screened velocity stacks. I don't have all the measurements, but I know that my carb needles/jets are not all stock so I am planning on tearing down the carbs again at some point to establish a baseline. Thanks for taggin' along!Originally posted by jibledso View PostHello! Great thread, it's helping me with my 77' 750 project. If you get the bike running before I get mine I'd love to know what your carb set up will be. I'm running a 4-1, not sure the make, and a K&N stock replacement, so similar to yours.

Good luck!

Comment

-

jibledso

jibledso

I know how you feel about feeling overwhelmed. I took on a 71' Honda CB500/4 project that was just too much for me, mainly because I didn't do what you are doing by seperating segments and focusing on those. I rebuilt the top-end, spent a lot of money on machining it out to a 555cc, bench synced it, rode it around the block without a clutch and broke the shift seal. It was heart breaking to come back the next day and see a large amount of oil under the bike. I slowly began the process of trying to split the case and eventually gave up from frustration. I sold it to a guy for $200 just to get rid of it, it didn't have a title.Originally posted by Zagg View PostAwesome! Good luck! I have had mine for a while now. Seemed daunting at first, but focus on one part of the bike makes it doable. The money tree is my biggest obstacle followed by time. I have a 4-1 Vance and Hines. I am ditching the air box for screened velocity stacks. I don't have all the measurements, but I know that my carb needles/jets are not all stock so I am planning on tearing down the carbs again at some point to establish a baseline. Thanks for taggin' along!

So, yeah this GS tidy up project is much better for my mind then a complete tear down and re-build.Last edited by Guest; 01-04-2017, 09:06 AM.

Comment

-

jibledso

jibledso

I wouldn't mind so how the velocity stacks home out either, seems best to leave them be but for looks they are incredible.Originally posted by Zagg View PostAwesome! Good luck! I have had mine for a while now. Seemed daunting at first, but focus on one part of the bike makes it doable. The money tree is my biggest obstacle followed by time. I have a 4-1 Vance and Hines. I am ditching the air box for screened velocity stacks. I don't have all the measurements, but I know that my carb needles/jets are not all stock so I am planning on tearing down the carbs again at some point to establish a baseline. Thanks for taggin' along!

Comment

-

Onlt $20 to get that dent out?

Do it.#1: 1979 GS 550 EC "Red" – Very first Bike / Overhaul thread New here? ☛ Read the Top 10 Newbie mistakes thread

#2: 1978 GS 550 EC "Blue" – Can't make it a donor / "Rebuild" thread Manuals (and much more): See Cliff's homepage here

#3: 2014 Moto Guzzi V7 II Racer – One needs a runner while wrenching

#4: 1980 Moto Guzzi V65C – Something to chill

Comment

-

[QUOTE=Zagg;2358739]I do not have any pics of the bondo I used to fix the rust holes along the seems and the dents, but I had this briefly...

May I suggest while it's in this sate, not knowing how bad your pinholes of rust were at the seams, to grind away the bondo there, and re-do the repair with JB Weld. The gas, if there are actual holes, will eat right trough bondo or plastic filler in no time and your new paint job will be ruined. I've seen that happen to too many home projects.1979 GS1000S,

1982 Honda CX500 Turbo, 1982 Honda MB5 w/CR80 motor, 1977 Honda "nekid" Goldwing, 1976 Honda CB550F cafe', 1972 Honda XL250 cafe'

Comment

-

Zagg

Zagg

Well, not exactly. $20 was what I have invested in bondo, sandpaper, and the first couple rattle cans. What I mean is that instead of $100+ for a new tank, I could get this one decent for what I have invested already.Originally posted by roeme View PostOnlt $20 to get that dent out?

Do it.

Comment

-

Zagg

Zagg

[QUOTE=nvr2old;2358879]Oh man. I did not know that. Okay, well I guess it's back to the drawing board then. Thanks a lot that is very helpful!Originally posted by Zagg View PostI do not have any pics of the bondo I used to fix the rust holes along the seems and the dents, but I had this briefly...

May I suggest while it's in this sate, not knowing how bad your pinholes of rust were at the seams, to grind away the bondo there, and re-do the repair with JB Weld. The gas, if there are actual holes, will eat right trough bondo or plastic filler in no time and your new paint job will be ruined. I've seen that happen to too many home projects.

Comment

-

JB Weld is gas "resistant". It's not a 100% guarantee fix, but it'll give you a much better chance of success. If there's even the slightest leak of gas, anywhere, your paint will be infected and will bubble. I always had good luck before starting any body work to take a pin-holed tank (stripped to bare metal) into a radiator repair shop. They can find the leaks and seal them just like they do a radiator, line the tank, and then pressure test for any pin holes. Unfortunately you've already done the body work and the submerged process would ruin that. That's why the JB Weld is basically a plan B. At this point I would also advise once the plastic filler is ground completely off to follow up with a stiff wire wheel on a drill. You need to actually re-open the pinholes so that the JB Weld will re-fill them. If you don't, the gas will seep through the plastic filler in the pin holes and there's a chance it will find it's way up and through the edges of the JB Weld. Good luck on your project.Last edited by nvr2old; 01-05-2017, 01:51 PM.1979 GS1000S,

1982 Honda CX500 Turbo, 1982 Honda MB5 w/CR80 motor, 1977 Honda "nekid" Goldwing, 1976 Honda CB550F cafe', 1972 Honda XL250 cafe'

Comment

-

Zagg

Zagg

I didn't realize I was going down the wrong path on the repairs. Copy on the grind down. The P.O. had a mess of bondo on the bottom seams. I found the pinholes by grinding all that off down to bare metal. Thanks for the tips. I am heading back to the drawing board to re-think this one.Originally posted by nvr2old View PostJB Weld is gas "resistant". It's not a 100% guarantee fix, but it'll give you a much better chance of success. If there's even the slightest leak of gas, anywhere, your paint will be infected and will bubble. I always had good luck before starting any body work to take a pin-holed tank (stripped to bare metal) into a radiator repair shop. They can find the leaks and seal them just like they do a radiator, line the tank, and then pressure test for any pin holes. Unfortunately you've already done the body work and the submerged process would ruin that. That's why the JB Weld is basically a plan B. At this point I would also advise once the plastic filler is ground completely off to follow up with a stiff wire wheel on a drill. You need to actually re-open the pinholes so that the JB Weld will re-fill them. If you don't, the gas will seep through the plastic filler in the pin holes and there's a chance it will find it's way up and through the edges of the JB Weld. Good luck on your project.

Comment

.png)

Comment