1980/81 GS1000G US Spec UK import

Collapse

X

-

US Spec would have had a painted and pin striped front fender to match the painted and pin striped tank and side covers. The aftermarket Vetter fairing and luggage was, of course an American product. I'm pretty certain that UK market 1000Gs had a chrome front fender, and a paint job with more than just simple pin stripes.sigpic Too old, too many bikes, too many cars, too many things

-

eddypeck

eddypeck

There's a bill with the documentation for caliper rebuild and new master cylinder and I can see from the reservoir that the brake fluid is still a nice clean and clear colour. Also on the bill is details of a fork rebuild, with new seals and fresh fluid. It could probably benefit from new (progressive) springs at some point, just as an upgrade but as I know it's had some attention it's more of a nice to do than essential. It's also had a new clutch and can see from the colour of the oil leaking from the head :-( that the oil is clean and new. Although I will rebuild over the winter so a full service will be happening immanently.Comment

-

eddypeck

eddypeck

Looking at the condition of the front fender (or mudguard as we call them over hear) it looks new and possibly an aftermarket pattern part. So it may well have had a painted one originally. I've been looking at replacements as I think I'd prefer it painted rather than chrome, but there's no rush to change it. What's there looks the part even if it's not correct.US Spec would have had a painted and pin striped front fender to match the painted and pin striped tank and side covers. The aftermarket Vetter fairing and luggage was, of course an American product. I'm pretty certain that UK market 1000Gs had a chrome front fender, and a paint job with more than just simple pin stripes.

Question, were the painted ones painted metal or plastic?

As for the pin striping, it's had the tank, panels and rear section repainted at some point so no idea what the original colour was or how the decals looked but I like it how it is now. I would like to refresh it at some point, so if that time comes I'll need to make a decision on whether to go back to a stock colour with stripes etc. or do something else.Comment

-

Not sure if you meant "progressive" as a type of spring or a brand name, but I'd like to offer a suggestion on both points.

Progressive Suspension (brand name) offers some very nice products, no doubt. The stock springs in your 1000G are likely progressively-wound springs, but of a lighter material that requires some pneumatic assistance. All of the advertising hype of air-assisted suspension sounds good, and it actually feels pretty good, until the air leaks out. Then you are left with rather inadequate springs.

Progressive (brand) springs are of a heavier spring rate than the stock springs, you likely will not need to use any additional air. However, in the process of adding enough preload to the springs so your suspension is set correctly, you might use up all of the 'softer' portion of the spring. Then you lose some of the hyped 'softer ride' and go to the stiffer portion of the springs. Many of us prefer the action of a straight-rate spring, instead. The air that is inherently trapped when you close the top of the fork tube also acts as a progressive spring, so rather than having two progressive springs compounding the rate, it's better to use straight-rate metal springs and leave the progression to the trapped air.

Sonic Springs fill that niche rather nicely, and the owner of the company happens to be a member here. Until recently, we had four GSes in the "stable" here. Three of them had Progressive fork springs, one has Sonic. I prefer the ride and control of the bike with Sonic springs. Of course, it happens to be MY bike, but I do ride the others on occasion for comparison.

.sigpic

mine: 2000 Honda GoldWing GL1500SE and 1980 GS850G'K' "Junior"

hers: 1982 GS850GL - "Angel" and 1969 Suzuki T250 Scrambler

#1 son: 1986 Yamaha Venture Royale 1300 and 1982 GS650GL "Rat Bagger"

#2 son: 1980 GS1000G

Family Portrait

Siblings and Spouses

Mom's first ride

Want a copy of my valve adjust spreadsheet for your 2-valve per cylinder engine? Send me an e-mail request (not a PM)

(Click on my username in the upper-left corner for e-mail info.)Comment

-

Hi I would recommend you get Oem gaskets for at least the cylinder base and head and orings on cylinder base along with the tear drop orings ( cylinders to crankcase) be aware though the cost is pretty steep suzuki are now issuing multi steel layer head gaskets ?100+

if you use the MLS gasket suzuki recommend you do not use the oblong oring that goes around the cam chain tunnelThe big guy up there rides a Suzuki (this I know)

1981 gs850gx

1999 RF900

past bikes. RF900

TL1000s

Hayabusa

gsx 750f x2

197cc Francis Barnett

various British nailsComment

-

eddypeck

eddypeck

OK, so a little update on the head gasket issue. No action, but I've been reading up and gathering info to the point where I decided to take make some purchases.

From various eBay sellers I've found NOS genuine Suzuki gaskets for the Head and base gaskets and cam chain o-ring, saving me a fair amount compared to the main dealer price. The head gasket is the original type not the MLS one, but information suggested this was more forgiving so when I get it apart I'll see if I can get away without skimming.

For the rest of the parts I've ordered a Vesrha full engine gasket kit direct from Japan, reviews were mixed on this brand but seemed to be generally more positive than Athena kits. There's a few other gaskets that I may still swap out for OEM ones before I actually kick off, but for now at least I've started the ball rolling.

On VesrahVesrahComment

-

Just caught up with you on here (I'm the Admin on the UK GS Suzuki Owners Group) and I love the pics. I have several GS1100Gs which are pretty similar (1982 and 1983).

I also run a mobile motorbike Dyno (www.dynABike.co.uk) and have done a few dyno runs over the last year. Including a run on my own GS1100G:

Compare yours to mine. The biggest issue I can see is that your Air/Fuel ratio suddenly drops from mid range to max revs and you are running pretty rich at that level.

On mine you can see a little dip in the A/F level around 6K rpm which I can cure with a needle clip adjustment.

On yours you might need to look at your main jet which is mostly likely to be what is causing this richness in that range.

Going a size down will give you better top end and better mileage.Richard

sigpic

GS1150 EF bought Jun 2015

GS1150 ES bought Mar 2014: ES Makeover Thread AND blog: Go to the Blog

GS1100 G (2) bought Aug 2013: Road Runner Project Thread AND blog: Go to the Blog

GS1100 G (1) Dad bought new 1985 (in rebuild) see: Dad's GS1100 G Rebuild AND blog: Go to the Blog

Previously owned: Suzuki GS750 EF (Canada), Suzuki GS750 (UK)(Avatar circa 1977), Yamaha XT500, Suzuki T500, Honda XL125, Garelli 50

Join the United Kingdom (UK) Suzuki GS Facebook Group hereComment

-

eddypeck

eddypeck

Thanks for the advice, I'm never really sure how to read a dyno chart but interesting to see the difference in mine and your chart. Priority is to stop it leaking oil, then I can take a look into getting it running better. I presume, with a leaking head gasket I must be down on compression? Even though it goes well, certainly better than I was expecting since I'm coming from much more modern super sports bikes.Comment

-

eddypeck

eddypeck

So, the bike's been parked up since the end of October.

The full aftermarket gasket kit arrived from Japan, the NOS head gasket arrived from the states but was damaged so I had to find another one, which arrived safe and sound - eBay refunded the first one.

NOS base gasket and a genuine cam chain o-ring found locally and purchased off eBay.

You might think it's a bit of a faff gathering all these parts but I have to say it's saved me a small fortune compared to going to a Suzuki dealer.

I was off work over Christmas but didn't get chance to pop out to the garage as I had some decorating to do to keep the family happy. But I've just had a week off work, did some more decorating, but did manage a couple of sessions on the bike.

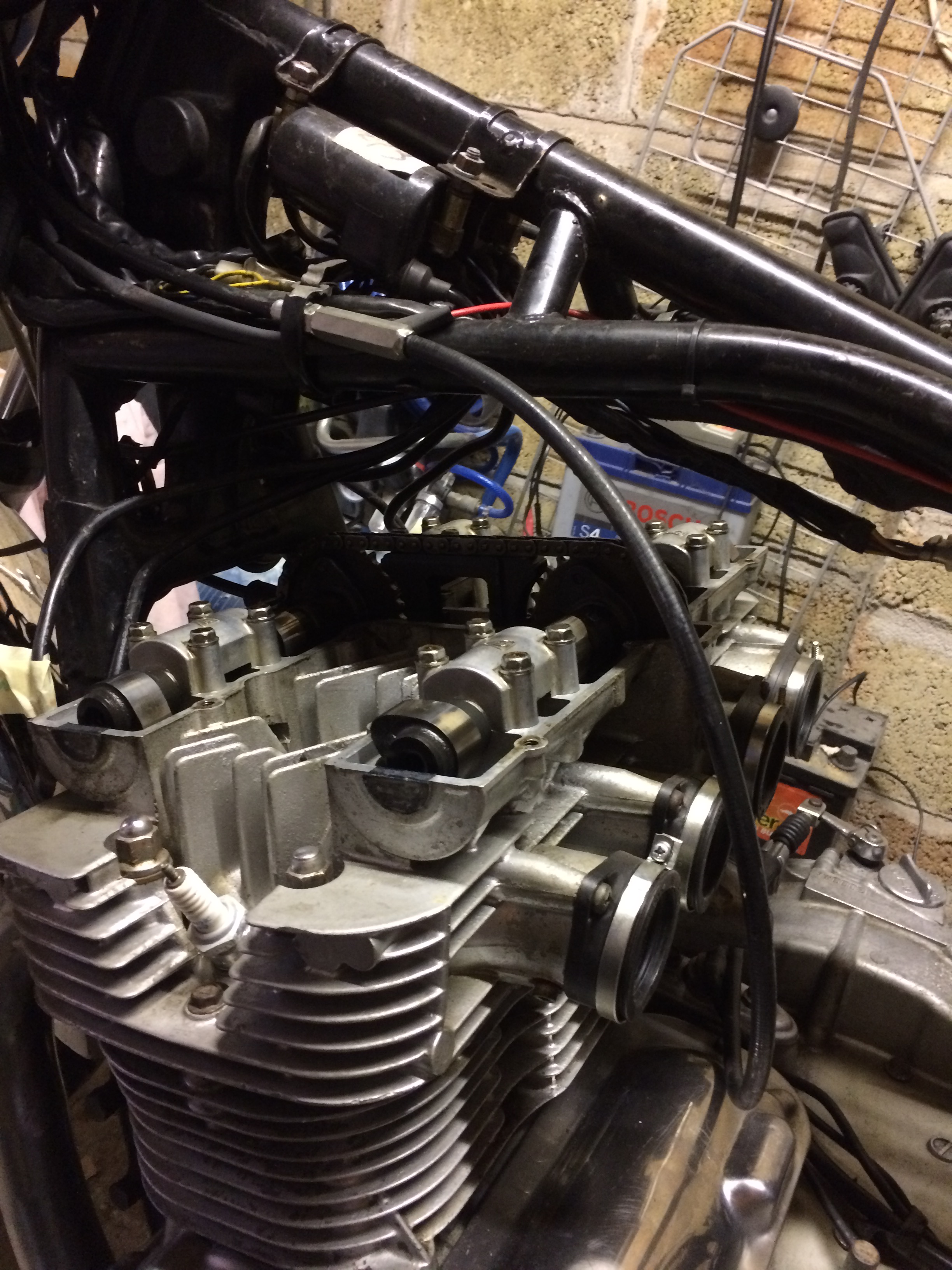

so it started:

and before long looked like this:

at which point I started getting very nervous having never gone this deep into an engine before, and then suddenly:

That was enough for one the first day.Comment

-

eddypeck

eddypeck

So what did I find?

Well after market head and base gaskets for a start, and this:

The egg shaped O-ring was there but had been sealed in with a little extra help. Is wasn't leaking obviously from this area but it could be seen to be damp from one of the earlier photos.

For day two I cracked out the over the top power tool:

To make these, as spec'ed in the Clymer manual. I had to work in inches, which I'm not used to over here!

After reading another thread where someone damaged the base gasket while fitting the cylinder I got a bit nervous again. But I wasn't convinced with fixing the gasket to the base of the cylinder and holding it in place with elastic bands as suggested. So I fitted it to the deck of the crank case, and cut out some cardboard to protect it, and with the wooden blocks and I have to say it was all very straight forward.

The valves looked like this after a bit of a clean up:

I then went ahead and fitted the head:

At this point the nuts are finger tight and the head is just sitting there.

And then had a change of heart....

I only have a large 1/2" torque wrench with a 30 to 210 nm range. The head bolts are supposed to be 36.6 or there about and I decided the range of mine was too wide to be that accurate. So I'm currently waiting for a 3/8" one with a 10-80 range to arrive.

I also thought, actually let's not cut corners, let's do this right. So I've ordered some lapping compound; course and fine, a valve spring compressor and some other bits and bobs. So when those arrive, hopefully in a few days I'll whip off the head, clean up the valves, pop them out, try and lap them in properly and fit the new oil seals since they came in the kit anyway.

Also ordered new plugs, oil and filter for when I'm done. Can't wait to crack on, but also want to take my time do it right and hopefully do it once.Comment

-

eddypeck

eddypeck

Tools and parts have all arrived now.

I made a start cleaning up the head

Now my valve spring compressor and lapping paste has arrived, this evening I'm hoping to take out the valves and finish the jobComment

-

Nice work Eddy!

I have my bike somewhat apart at the moment. Seeing yours with tank/carbs/headlight off is how mine is sitting.

EdGS750TZ V&H/4-1, Progressive Shocks, Rebuilt MC/braided line, Tarozzi Stabilizer[Seq#2312]

GS750TZ Parts Bike [Seq#6036]

GSX-R750Y (Sold)

my opinion shouldn't be taken as gospel or in any way that would lead you to believe otherwise (30Sep2021)

Comment

-

eddypeck

eddypeck

So the weekend brought me a puzzling situation.

With my newly acquired valve spring compressor I preceded to remove the valves. I might add, although a little daunting as I've never got this involved in a mechanical build before, the process was fairly straightforward. One thing I have learnt over the years is how much simpler a task is with the right tools.

Anyway I followed the Clymer manual, compressed the springs popped out the split keeper, released the tool and removed the top hat and springs, and dropped the valve out the bottom.

Then when it came to the bit about using needle nose pliers to remove the oil seals nothing seemed to move and things didn't look right. I tried to get some photos or videos to see if I could compare what I was looking at and found a YouTube video that suggested heat - I didn't go this far.

But I was beginning to suspect the valve seals weren't actually there. At first I thought maybe the rubber parts had gone and I was looking at the shell, then I tried a new seal and saw it fitted over the top. I eventually worked out, with confirmation from a few pics posted on Facebook, that the head had actually been rebuilt without valve guide oil seals fitted.... (or was it?)

That was what I was looking at, just the naked top of the valve guide.

However 2 of the valves came out with the remains of the seal...

Which was puzzling, how had this got onto the valve stem? Then I pulled a third that had the full oil seal still in situ and it dawned on me, they'd been fitted to the underside of the head on the hot side.

So the exhaust side ones were all gone, burnt up and blown out the exhaust no doubt. And of the inlet side, various bits remained, assuming the rest must had made it into the chamber - although no damage to pistons, valves or head luckily.

That mystery solved, I cleaned up the valves and head best I could. Lapped in the valves, another first for me and started to put it back together. So far only 2 inlet valves back in before I ran out of time. Those split keepers are fiddly. But I'm sure by the time I've done the other six I'll have got the knack of it. We're currently entering a cold spell again (not that it had really warmed up) apparently the next week is about to be the coldest week in the past five years - so still, no rush to get it back together but I am really looking forward to getting it done, especially now knowing things are getting done properly.

But I will be checking the whole bike over because I've no idea what other 'maintenance' the previous owners may have done and from what I've seen so far I've not been filled with confidence.Comment

-

FREAKY!

Never saw that before...1978 Gs1085 compliments of Popy Yosh, Bandit 1200 wheels and front end, VM33 Smoothbores, Yosh exhaust, braced frame, ported polished head :cool:

1983 Gs1100ESD, rebuild finished! Body paintwork happening winter 2017:D

I would rather trust my bike to a technician that reads the service manual than some backyardigan that THINKS HE KNOWS how to fix things.Comment

-

NickyGS750

NickyGS750

[QUOTE=Which was puzzling, how had this got onto the valve stem? Then I pulled a third that had the full oil seal still in situ and it dawned on me, they'd been fitted to the underside of the head on the hot side.[/QUOTE]

Wow, i cant even comprehend this... some peoples kids hahaComment

Comment