Announcement

Collapse

No announcement yet.

JohnnyL's 1980 GS550L Cafe Build

Collapse

X

-

No kidding. I wish I could build mine at just half the pace he's going at.Originally posted by Spyder View Post

-

That gauge may be mounted a little too flat, no? May be difficult to see it. Especially on a bright and sunny day? Superb work so far. Can't wait to see this thing done. Which by the looks of your progress, won't be very long from now...

Leave a comment:

-

Cool, I've always wondered about harbor freight welders. I've read good reviews, but have never known anyone personally with experience. I bought a 120-Volt 140 Amp Easy Weld FC-i Flux Core welder "used" (the guy bought it thinking he could convert it to gas but realized he couldn't and sold it.) I've never welded before, but following some online guides and with some practice I should be able to do a good enough job for my needs. I haven't really had the chance to practice with it much yet though. I already don't like flux core though, it's messy and requires more grinding but that's what you get for $100 off craigslist haha.Originally posted by JohnnyL View PostThanks. They're by no means purty welds but they are solid. I used to have a Lincoln flux welder and hated it. Only really used it once. I always wanted to learn how to weld but wanted to do it with a gas shielded welder. I broke down and bought a Vulcan OmniPro 220 from Harbor Freight with a 15% coupon. I gotta tell ya...this welder is the *@%^$*@%^$*@%^$*@%^$. Just dial in what thickness metal your welding and what size wire you're using and it does all the settings for you. I LOVE this thing.

Leave a comment:

-

Nice to see someone doing it up right! Can't wait to see the finished result.

Leave a comment:

-

Very nice work, Johnny.

No way i would powdercoat it.

You should be showing off that cool bit o' kit.

Leave a comment:

-

I finished up the triple clamp this morning. I'm pretty stoked on how it turned out. One more piece ready for powder coat.

Leave a comment:

-

I'm still undecided on color layout yet. I know it's going to be black, red and white. I have some ideas but just not sure yet.

Time to call it a day. I was able to get the triple clamp milled out today and a bracket to hold the gauge. I still need to cut slits for the clamps and drill and tap holes for the clamp bolts. I'm pretty happy so far.

Leave a comment:

-

Dam, you're not messin' around with this thing. Awesome progress so far.

What are you thinking for paint/scheme?

Leave a comment:

-

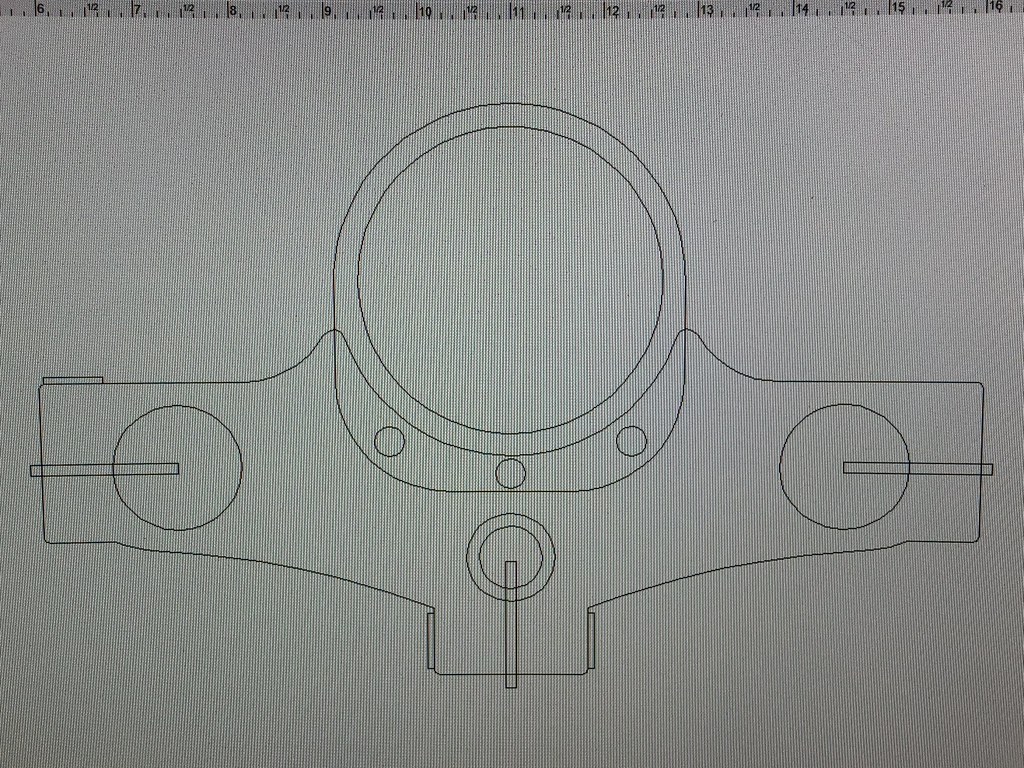

I have been thinking about my triple clamp and how I am going to mount my new all-in-one gauge. I thought about using the stock triple clamp but I'm not using the risers for handlebars since I will be using clip-ons. I then thought about grinding off the risers but if I do that, the casting is hollow underneath. So I've decided that I am going to pick up a chunk of 1" 6061 aluminum and machine my own triple clamp. This way I can have a clean looking install with my new gauge. I have drawn the triple clamp on the computer. Just need to pick up the aluminum.

Stock triple clamp

No good

New gauge

New triple clamp design from billet aluminum

Leave a comment:

-

Thanks. They're by no means purty welds but they are solid. I used to have a Lincoln flux welder and hated it. Only really used it once. I always wanted to learn how to weld but wanted to do it with a gas shielded welder. I broke down and bought a Vulcan OmniPro 220 from Harbor Freight with a 15% coupon. I gotta tell ya...this welder is the *@%^$*@%^$*@%^$*@%^$. Just dial in what thickness metal your welding and what size wire you're using and it does all the settings for you. I LOVE this thing.Originally posted by 93Bandit View PostI can't weld, but to my untrained eye I'd say those welds are really good for only a 3rd timer! What welder are you using?

I made a little shield for the back of the seat pan today so stuff won't get up underneath the cowling. I also think I am going to figure out a way to suck the back of cowling down to the frame. Hence the little tap you see on the shield.

Leave a comment:

-

I can't weld, but to my untrained eye I'd say those welds are really good for only a 3rd timer! What welder are you using?

Leave a comment:

.png)

Leave a comment: