Announcement

Collapse

No announcement yet.

rewinding a gs1000 speedo

Collapse

X

-

max parsons

max parsons

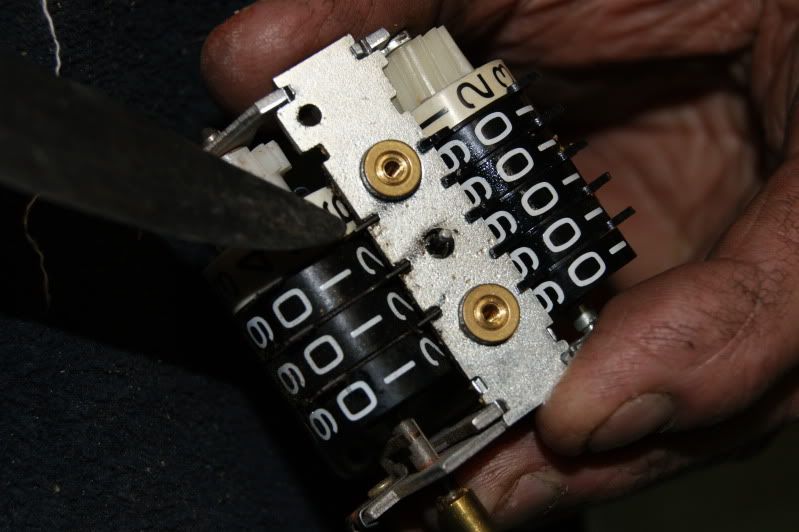

Now slide the black wheels to create space to turn the wheels.Start with the mile wheel and centre it in the gap and it will turn freely.When it's done mesh it into the white wheel and move onto the 10mile wheel.Keep going until you've got a brand new bike.

-

max parsons

max parsons

Now put the glasses back on to replace the clip.I use a pair of pliers to get the clip in position before flicking it back into place.

Comment

-

max parsons

max parsons

I had a tacho showing 11,000revs while stopped because of a broken spring.If you have this problem start by removing the clip that holds the trip meter in place.

Comment

-

max parsons

max parsons -

max parsons

max parsons

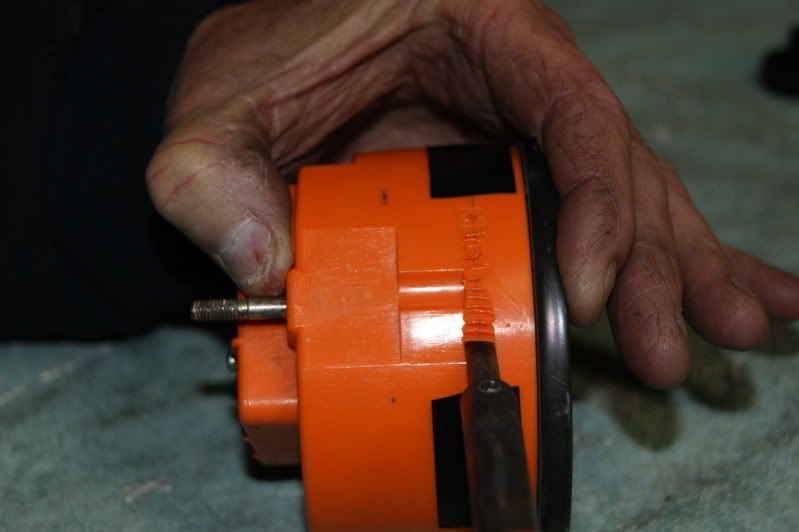

If your spring is broken use a strong,sharp knife to lever the spring holder open to remove the broken end,then hold the end of the spring in the holder and squeeze it back over.

Comment

-

max parsons

max parsons -

max parsons

max parsons

In one thread it recommended spraying the bell with silicone jet oil but none of Finleys jet builders had any so I used silicone spray on the bell and shaft.

Comment

-

max parsons

max parsons

When bolting the pieces back together ensure that the cover above the bell goes back in the right way as it stops the needle from dropping below 0.The needle pushes back on so line it up first.To check your work cut up an old cable to a manageable length,hook it into your electric drill and watch it go.Igot 125ks from the speedo and 8500revs.Make sure you run your drill in reverse.

Comment

-

max parsons

max parsons

After bolting the speedo back into the holder refit the seal and then using the manufacturing marks line up the 2 pieces.Then use some tape to hold the pieces together.

Comment

-

max parsons

max parsons

To hold the pieces together I use a soldering iron.If you touch on and off quickly you won't have any trouble.

Comment

-

max parsons

max parsons

As I have little faith in my soldering skills I follow up with a bead of 5 minute araldite.If you hold the join vertically and keep turning it while it dries you should end up with a neat join.

Comment

-

max parsons

max parsons -

max parsons

max parsons -

max parsons

max parsons

I had to pull my gauges apart to fix them and this was the last job needed for me to be able to say it was finished and like new.The Pig was reliable but rough when I got and it has taken all these years to get it finished,thanks in no small part to what I've learned on this site and as I will never buy a new bike I settled for winding back the speedo.I'm going on a 400km ride tomorrow so the numbers will build up quick enough.

Comment

.png)

Comment