Thanks.

Announcement

Collapse

No announcement yet.

Brake Rotors and Threadlock

Collapse

X

-

Brake Rotors and Threadlock

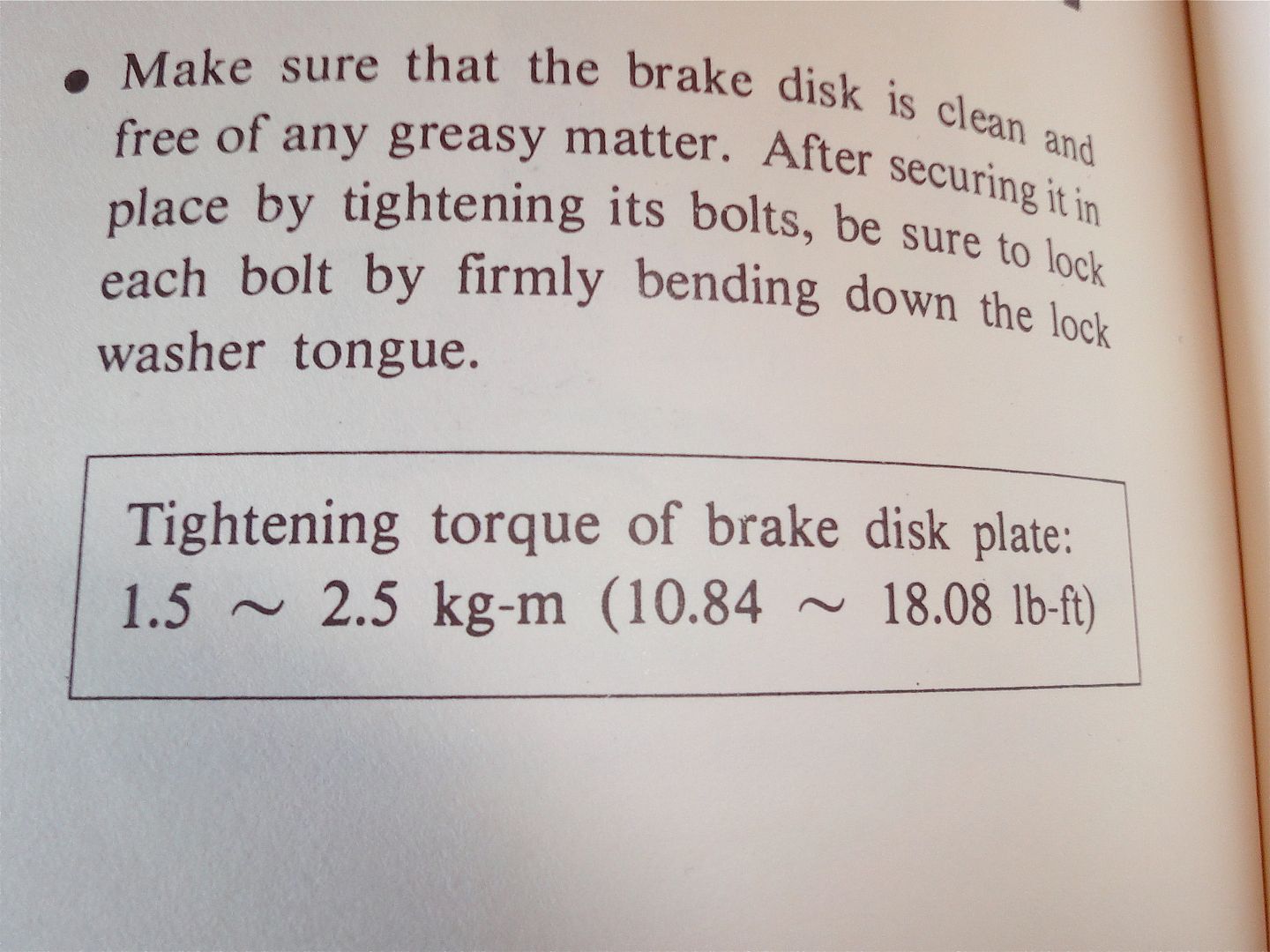

I couldn't find anything here to contradict my service manual but still wanted to ask. According to the service manual, I don't need threadlocker to put the brake rotors on. However, would it still be a good idea to use some? I ask as the old bolts have some kind of white gunk on them so I assume maybe someone had before.

Thanks.Cowboy Up or Quit. - Run Free Lou and Rest in Peace

1981 GS550T - My First

1981 GS550L - My Eldest Daughter's - Now Sold

2007 GSF1250SA Bandit - My touring bike

Sit tall in the saddle Hold your head up high

Keep your eyes fixed where the trail meets the sky and live like you ain't afraid to die

and don't be scared, just enjoy your ride - Chris Ledoux, "The Ride"Tags: None

-

7981GS

7981GS

Cowboy, I actually just put anti-sieze on the threads and torque to spec.

They aren't going anywhere and the locking tabs are more so that you can visually see if they get loose than to hold them in place.

BYW, the white crap is just years of oxidation. Be sure that you use a wire wheel/brush to clean the threads before you apply the anti-sieze.

DanielLast edited by Guest; 12-03-2011, 02:47 AM.

-

+1 Anti- seize will prevent the white oxidation. Don't think I have ever seen a brake disc come loose. And if it did you would see the lock tab being loose when you check the bike out before you ride.

Sprockets, on the other hand, loosen themselves once in a while. Probably there is a lot more vibration from the chain.

Comment

-

7981GS

7981GS

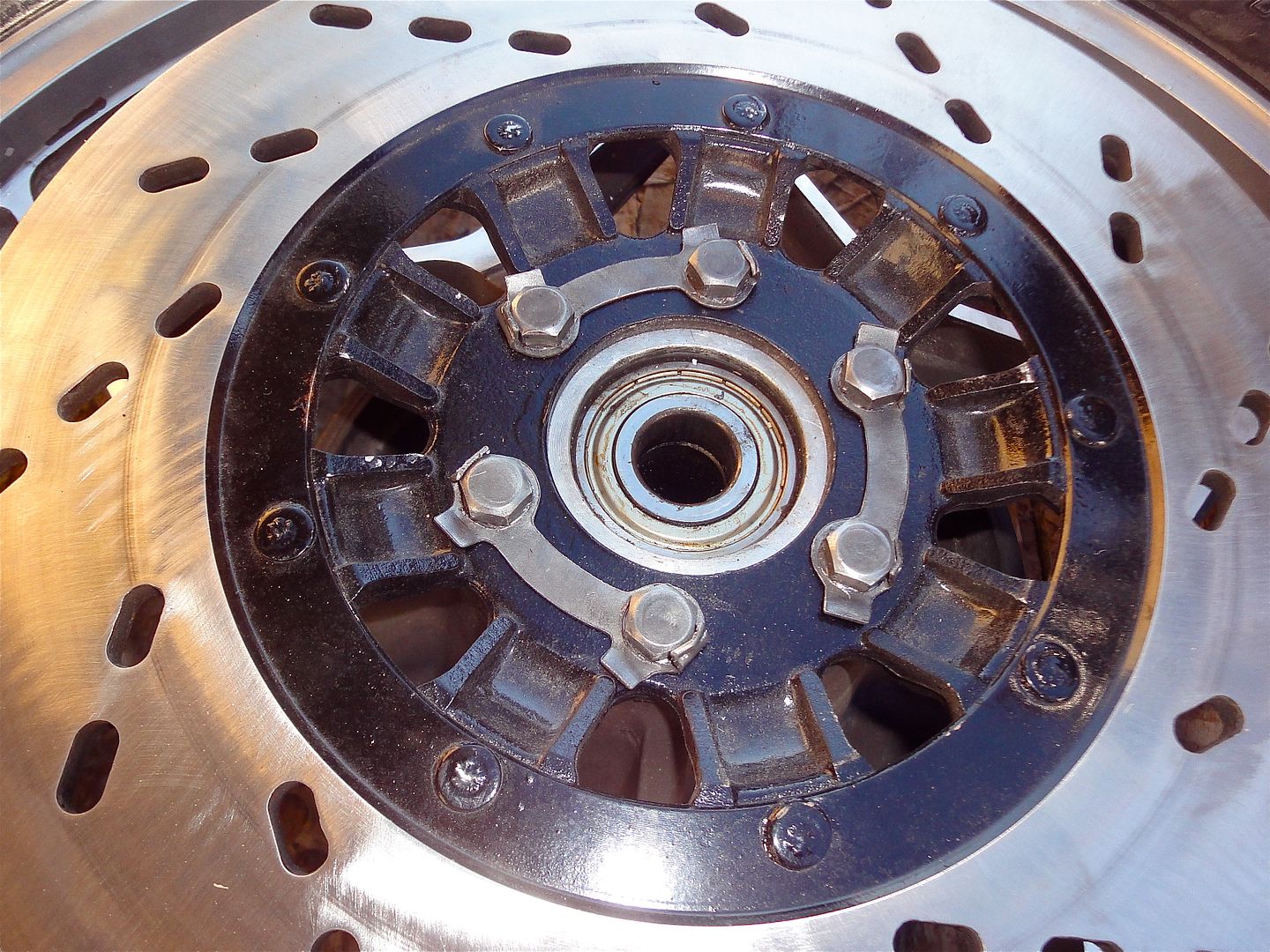

As I was busy doing the same thing,

I thought that I might take some pic's for you Cowboy.

Cleaned up bolts and keepers.

Just enough anti-sieze to fill the threads without having

any extend onto the bottom causing hydro-lock conditions.

Place ALL of the bolts in place before tightening down.

Factory recommendation.

As I am using anti-sieze, I torqued them to 25 Ft.Lbs.

Hope that helped.

Daniel

Comment

-

Um, why would that be necessary?Originally posted by 7981GS View Post...

As I am using anti-sieze, I torqued them to 25 Ft.Lbs.

...Dogma

--

O LORD, be gracious to me; heal me, for I have sinned against you! - David

Skeptical scrutiny is the means, in both science and religion, by which deep insights can be winnowed from deep nonsense. - Carl Sagan

--

'80 GS850 GLT

'80 GS1000 GT

'01 ZRX1200R

How to get a "What's New" feed without the Vortex, and without permanently quitting the Vortex

Comment

-

7981GS

7981GS

Most bolts will have a dry and a wet torque value.Originally posted by Dogma View PostUm, why would that be necessary?

As the anti-sieze has less friction (is a little more slippery) than metal to metal,

it is safe to go a wee bit higher as you are still actually at the same torque if it were not lubricated.

For example, go to ARP Fastener's site (the industry standard for high grade bolts/ fasteners) and they

will give you multiple torque specs for their bolts with or without their lubricant.

And another for bolts dipped in motor oil.

Daniel

Comment

-

I poked around for a while and never found any examples of multiple torque specs given. Anyhow, if a lubricant is going to influence a torque spec, why would it be higher instead of lower?Dogma

--

O LORD, be gracious to me; heal me, for I have sinned against you! - David

Skeptical scrutiny is the means, in both science and religion, by which deep insights can be winnowed from deep nonsense. - Carl Sagan

--

'80 GS850 GLT

'80 GS1000 GT

'01 ZRX1200R

How to get a "What's New" feed without the Vortex, and without permanently quitting the Vortex

Comment

-

GateKeeper

GateKeeper -

Normk

Normk

Loctite recommend reducing torque by 10% in order to treat their product as a lubricant.

It is not advised to go higher because the torque specification is intended to provide sufficient twisting effort to overcome thread friction, clamping surface friction, and to tension the fastener to the desired degree. Anything which reduces friction, given the same torque, will necessarily increase tension. Increasing tension out of the elastic range into yield is not productive.

Torquing to a specified limit is one of the least accurate means of arriving at the desired fastener tension but is convenient and accurate enough for less critical applications. Modern automotive (and many motorcycle) cylinder head tension specifications use "torque to yield method" which is similar to the "torque turn" technnique used for larger and more critical applications for many decades.

Comment

-

Spot on.Originally posted by Normk View PostLoctite recommend reducing torque by 10% in order to treat their product as a lubricant.

It is not advised to go higher because the torque specification is intended to provide sufficient twisting effort to overcome thread friction, clamping surface friction, and to tension the fastener to the desired degree. Anything which reduces friction, given the same torque, will necessarily increase tension. Increasing tension out of the elastic range into yield is not productive.

I don't bother with those locking tabs. All the second hand ones over here are rusted out and the new ones are I think made of platinum. Green Loctite was the favourite over here for many years but nobody ever planned to take the discs off again (can be done but it's the devil). So blue is the way to go now - the bolts don't fall out. There's an awful lot of bikes that come out of the factory without the tabs or similar so they're not worried.79 GS1000S

79 GS1000S (another one)

80 GSX750

80 GS550

80 CB650 cafe racer

75 PC50 - the one with OHV and pedals...

75 TS100 - being ridden (suicidally) by my father

Comment

-

SVSooke

SVSooke

The 81 Honda CB750 has no tabs(5 bolts) so they weren't worried abot the bolts backing out.I keep them cause I like the look.

Comment

-

So, I will just put a dab of loctite on, torque them to spec, and pull the tabs up again. Thanks fellas.Cowboy Up or Quit. - Run Free Lou and Rest in Peace

1981 GS550T - My First

1981 GS550L - My Eldest Daughter's - Now Sold

2007 GSF1250SA Bandit - My touring bike

Sit tall in the saddle Hold your head up high

Keep your eyes fixed where the trail meets the sky and live like you ain't afraid to die

and don't be scared, just enjoy your ride - Chris Ledoux, "The Ride"

Comment

-

Normk

Normk

Contrary to popular belief, the biggest advantage to using blue Loctite is that it seals the threads reasonably well and so excludes corrosion which makes the fasteners easier to remove. Excellent product.

Even the "permanent" Loctite releases easily with some heat and none of these products are effective on exhaust temperature fasteners.

We really should do a comprehensive fasteners thread as there is much misunderstanding.

Do yourself a big favor and make absolutely sure of the mouting surfaces for disk and rotor. Even a few thou' of run-out will give you fits in terms of vibration.

Comment

-

TheCafeKid

TheCafeKid

I'd picked up a suggestion recently regarding prepping mating surfaces of which run-out is critical (like this one). Using a whetstone to clean and smooth both surfaces. Ive tried it and it really cleans them up nicely.

Comment

-

Well, I actually sat and thought about what I was doing yesterday and changed my mind on this. I put the antisieze, torqued it down properly, but forgot to close up the locking tabs so I still need to do that.

I'm curious though Norm as to how to check the runout like you are saying? Is it something I will see (as in a bent rotor) or something I should check with a gauge? Where should I make my measurements?Cowboy Up or Quit. - Run Free Lou and Rest in Peace

1981 GS550T - My First

1981 GS550L - My Eldest Daughter's - Now Sold

2007 GSF1250SA Bandit - My touring bike

Sit tall in the saddle Hold your head up high

Keep your eyes fixed where the trail meets the sky and live like you ain't afraid to die

and don't be scared, just enjoy your ride - Chris Ledoux, "The Ride"

Comment

.png)

Comment